At Tracerco, we are proud to spotlight the people behind our pioneering technologies, individuals like Patrick Hayes, whose career journey and passion for innovation exemplify what it means to grow with us.

Based in Houston, Texas, Patrick is our Global Development Manager in the Reservoir business unit, where he plays a key role in shaping the future of our business and delivering measurable value to customers around the world.

Patrick’s role is as dynamic as it is impactful.

“It’s all about collaborating with exceptional talent, driving opportunity development, and enhancing customer awareness of Tracerco’s innovative solutions across key regions and industries,” he explains.

Read More

Topics:

people,

employee recognition,

Life at Tracerco,

Working Lives,

Colleague Forum

When Jordan Crawford first stepped into Tracerco, it was meant to be temporary. Thirteen years later, she’s a cornerstone of the Diagnostic Services team, proving that great opportunities often begin with a simple “why not?”

Read More

Topics:

people,

employee recognition,

Life at Tracerco,

Working Lives,

Colleague Forum

When Junaid Badar, Tracerco’s Business Development Manager, attended the IAEA Emergency Preparedness and Response (EPR) Conference, he expected a valuable experience. The event exceeded expectations as the discussions closely reflected the work Tracerco does in radiation safety and radiation detection.

Read More

Topics:

Awards,

dose rate,

monitoring,

radiation,

monitors,

ped,

personal electronic dosimeter,

radiation monitor,

radiation detection,

dosimeter

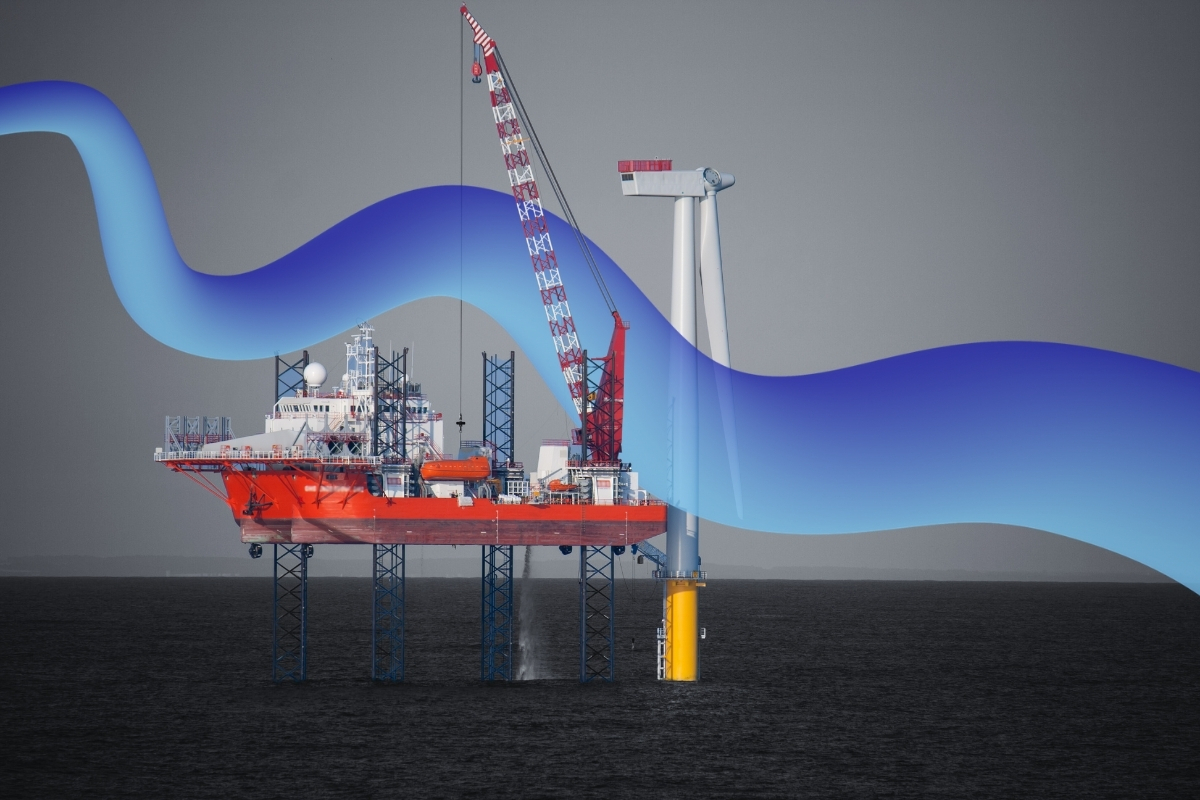

Offshore sector in Asia is entering an exciting phase. Deepwater oil and gas remain crucial, while offshore wind is rising as countries push for cleaner, independent energy.

As activity grows in both areas, operators are looking for better ways to ensure asset integrity and efficient operations. Successful completion of two major subsea projects in Southeast Asia demonstrating how Tracerco's technologies support both traditional and renewable energy markets.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Asset Integrity,

subsea pipelines,

Subsea Inspection,

Subsea Integrity,

pipeline life extension,

pipeline extension,

CT scanner,

grout monitoring

Tracerco is proud to spotlight Max Smithson, a Software Apprentice in our Process Diagnostic and Innovation (PD and I) Department, whose journey is a brilliant example of how curiosity, hands-on experience, and a supportive environment can shape a rewarding career in technology.

Read More

Topics:

people,

employee recognition,

Life at Tracerco,

Working Lives,

Colleague Forum

At Tracerco, we believe in the power of people to drive innovation, strategy, and success, especially in regions like Saudi Arabia where energy innovation is accelerating. One of those people is Anas Qutob, our General Manager - Sales for Saudi Arabia, who is helping shape the future of our business in the region.

Read More

Topics:

people,

employee recognition,

Life at Tracerco,

Working Lives,

Colleague Forum

At Tracerco, we believe that behind every breakthrough is a passionate individual driving it forward. One such person is Ros Arniza Ahmad Rodzli, a Senior Analytical Chemist at our Kuala Lumpur base in Malaysia, who has been a cornerstone of our Reservoir business unit for over a decade.

Read More

Topics:

people,

employee recognition,

Life at Tracerco,

Working Lives,

Colleague Forum

At Tracerco, we don’t just offer jobs, we build careers, foster belonging, and create space for people to thrive. For Anna, our Commercial Contracts Manager in the Measurement Instruments Business Unit, that journey has been both personal and transformative.

Read More

Topics:

people,

employee recognition,

Life at Tracerco,

Working Lives,

Colleague Forum

For the first time in the United States, our proprietary chemical tracer technology has been applied to a Carbon Capture and Storage (CCS) project. This achievement strengthens the way operators monitor CO₂ injection and containment, offering independent verification that underground storage remains safe and permanent.

Read More

Topics:

chemical tracers,

tracers,

chemical tracer technology,

Carbon capture and storage,

CCUS,

CCS

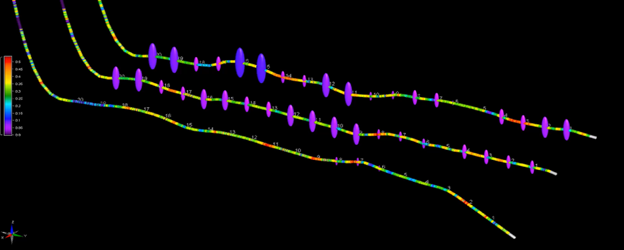

In the oil and gas industry, getting the most out of every reservoir is more important than ever. Drilling engineers are expected to improve performance, manage costs, and reduce risk all while making faster, better decisions in the field. To do that, they need more than good planning and the latest oil tools. They need the right data.

Read More

Topics:

reservoir characterisation,

fluid inflow,

reservoir production modeling,

tracers

.jpg)

.png)

.jpg)