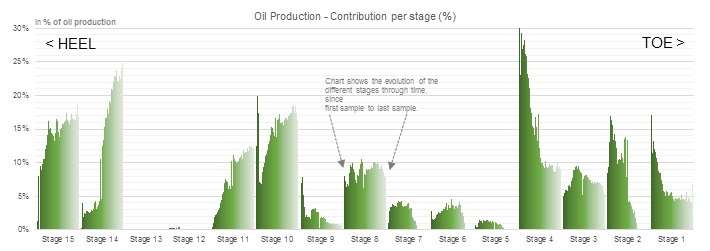

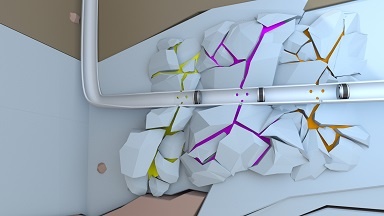

Selection of the stimulation target in unconventional shale formations is an important factor that impacts well productivity. In thick unconventional formations, it is essential that operators quantify the production of each stage of hydraulic fracturing executed in the well, in order to establish the most productive rock. It is also important for operators to be certain that every section of the stimulated well is effectively contributing to overall well production and clean-out of all stages has been achieved. In addition, other development challenges include optimal spacing between perforation clusters, stages and wells, allowing operators to optimize drilling and completion costs and maximize enhanced ultimate recovery (EUR).

This Blog describes the application of chemical tracers in a multi-stage horizontal well to gain insight on stage productivity in order to plan an optimal field development strategy.

Read More

Topics:

chemical tracers,

unconventional wells,

reservoir,

fracking,

reservoir characterisation,

tracers,

unconventional oil and gas,

smart tracers,

tracer technology,

frac wells,

shale,

shale production,

well development

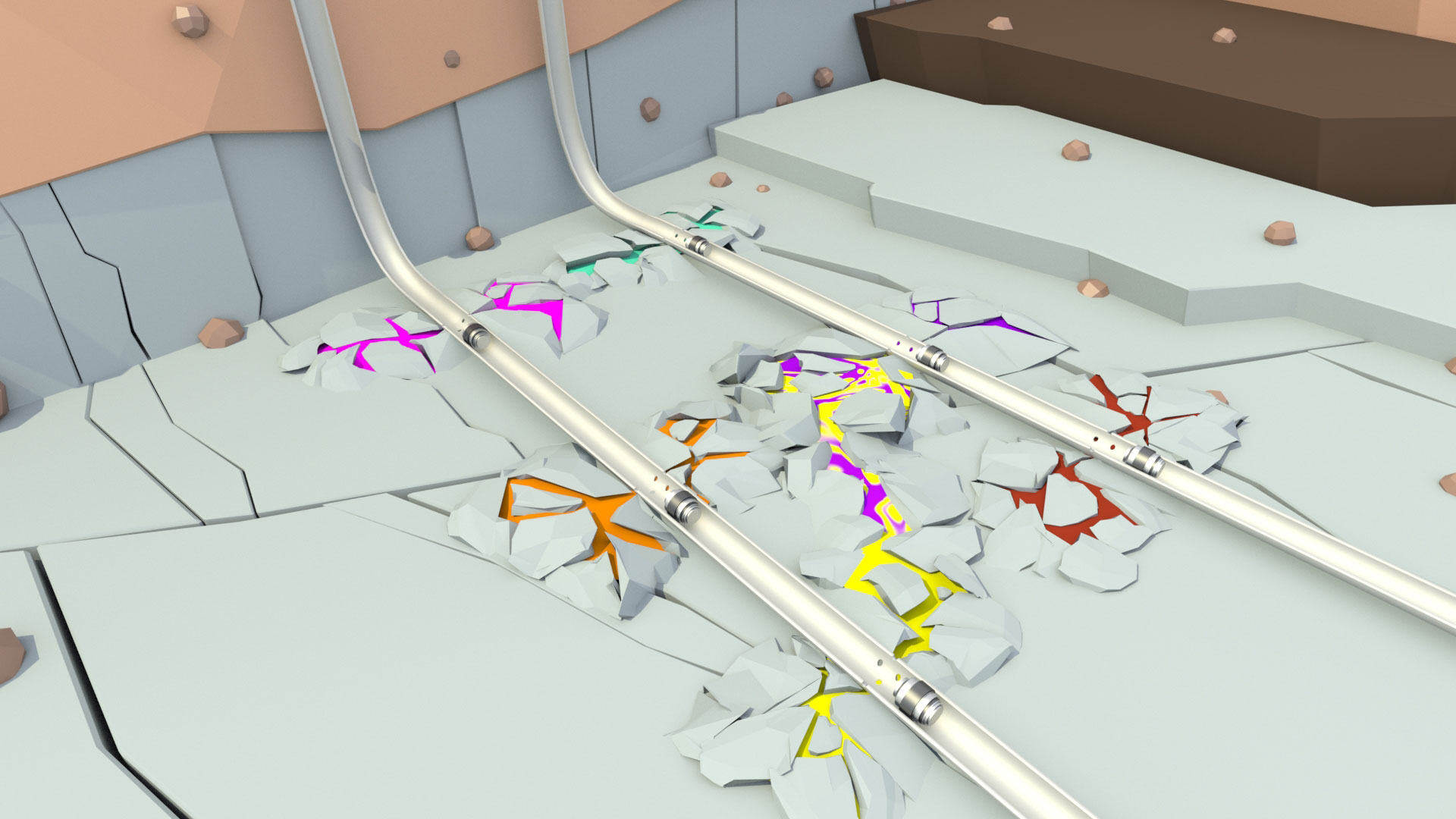

Tracerco, patented, pioneered and continues to enhance technology that enables the measurement of individual gas, oil, and water stage production along the length of a wellbore, without well intervention. This inexpensive technology provides confirmation that a wellbore is open to flow, identifies and quantifies stage flow contribution of each phase, and provides measurement of drainage area connectivity - simply by adding small amounts of unique chemical tracers to each stage’s stimulation fluid.

Read More

Topics:

chemical tracers,

unconventional wells,

reservoir,

fracking,

reservoir characterisation,

tracers,

unconventional oil and gas,

smart tracers,

tracer technology,

frac wells,

shale,

shale production,

well development

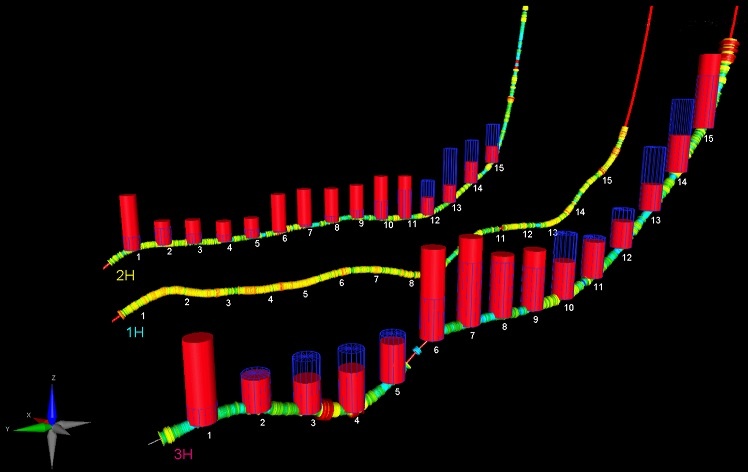

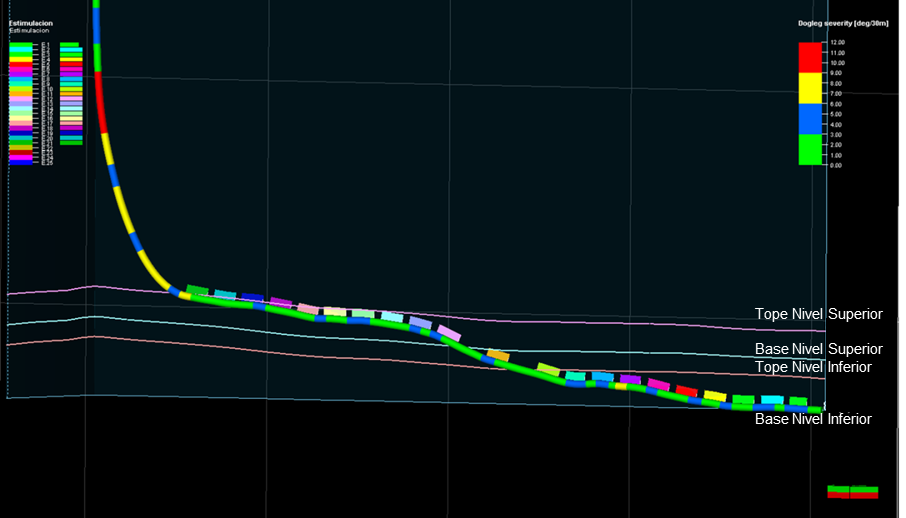

A customer wanted to test two different lithologies and compare the performance of both, in the gas window of the Neuquén Basin, in Argentina. For that reason, a slanted two-horizon target well was drilled, distributing 10 stages in the upper zone, and 10 stages in the lower zone. The intermediate zone, which was not considered a main target, received one stage.

21 unique organic gas and water tracers were added to each of the different stages of the well during stimulation. The injection was controlled and care was taken to tag all stages in the same way, ensuring that the tracers would penetrate deep into the fracture structure and make contact with formation hydrocarbons. Subsequent flowback and sample analysis for the presence of the injected tracers allowed relative gas and water flow from the different stages to be evaluated.

Read More

Topics:

chemical tracers,

unconventional wells,

reservoir,

fracking,

reservoir characterisation,

tracers,

unconventional oil and gas,

smart tracers,

tracer technology,

frac wells

Understanding zonal contribution is imperative when developing stacked plays where a primary appraisal objective is to quantify zonal productivity to determine which layers of the formation to target. One proven evaluation method is the use of chemical-based tracer technology. In this blog post we will provide a real case example of where chemical tracer technology was used to determine zonal contribution and assist in the planning of future well and field development.

Read More

Topics:

chemical tracers,

unconventional wells,

reservoir,

fracking,

reservoir characterisation,

unconventional oil and gas

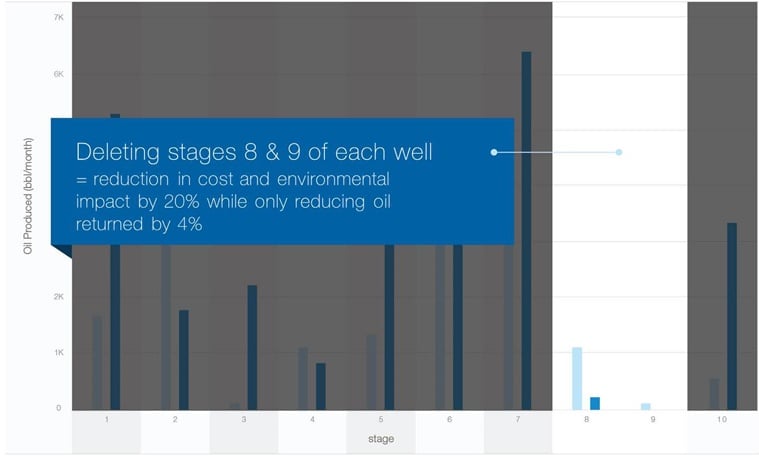

In the challenging market conditions that we face today, reducing lift costs is paramount. One area where this can be achieved is through stimulation optimisation, ensuring reduce spend on stimulation activities and maximum oil or gas flow for a particular field.

In this post we examine five steps to achieving savings of as much as 20% in reservoir stimulation costs by using accurate flow data to optimise stage stimulation in individual wells and development of unconventional fields.

This is based on our vast experience across numerous fields and the insights and figures are taken from real projects conducted over the last few years.

Read More

Topics:

unconventional wells,

reservoir,

reservoir analysis,

reservoir characterisation,

drilling,

technology enabling cost savings,

reservoir stimulation

Tracerco is tailoring our offering to meet the needs and challenges of our customers with five brand new tracer labs to analyse reservoir samples.

Read More

Topics:

Tracerco innovations,

chemical tracers,

unconventional wells,

reservoir,

fracking,

controlled release,

flow profiling,

reservoir analysis,

tracer analysis,

interwell

With the oil price remaining low, the entire oil and gas industry together with their supply chain are faced with the challenge of producing more for less. Constantly looking to cut costs without compromising on production or quality of product, technologies demonstrate their value not only in how they can help optimise production at any stage in the hydrocarbon production and processing chains, but also in how they can act as enablers to operators who need to save on the cost of producing oil and gas.

In this post we examine three steps to achieving savings of as much as 66% in drilling costs by using accurate flow data to optimise well spacing in unconventional fields. Tweet this.

This is based on our vast experience across numerous fields and the insights and figures come from real projects conducted over the last few years.

Read More

Topics:

unconventional wells,

reservoir,

reservoir analysis,

reservoir characterisation,

drilling,

technology enabling cost savings