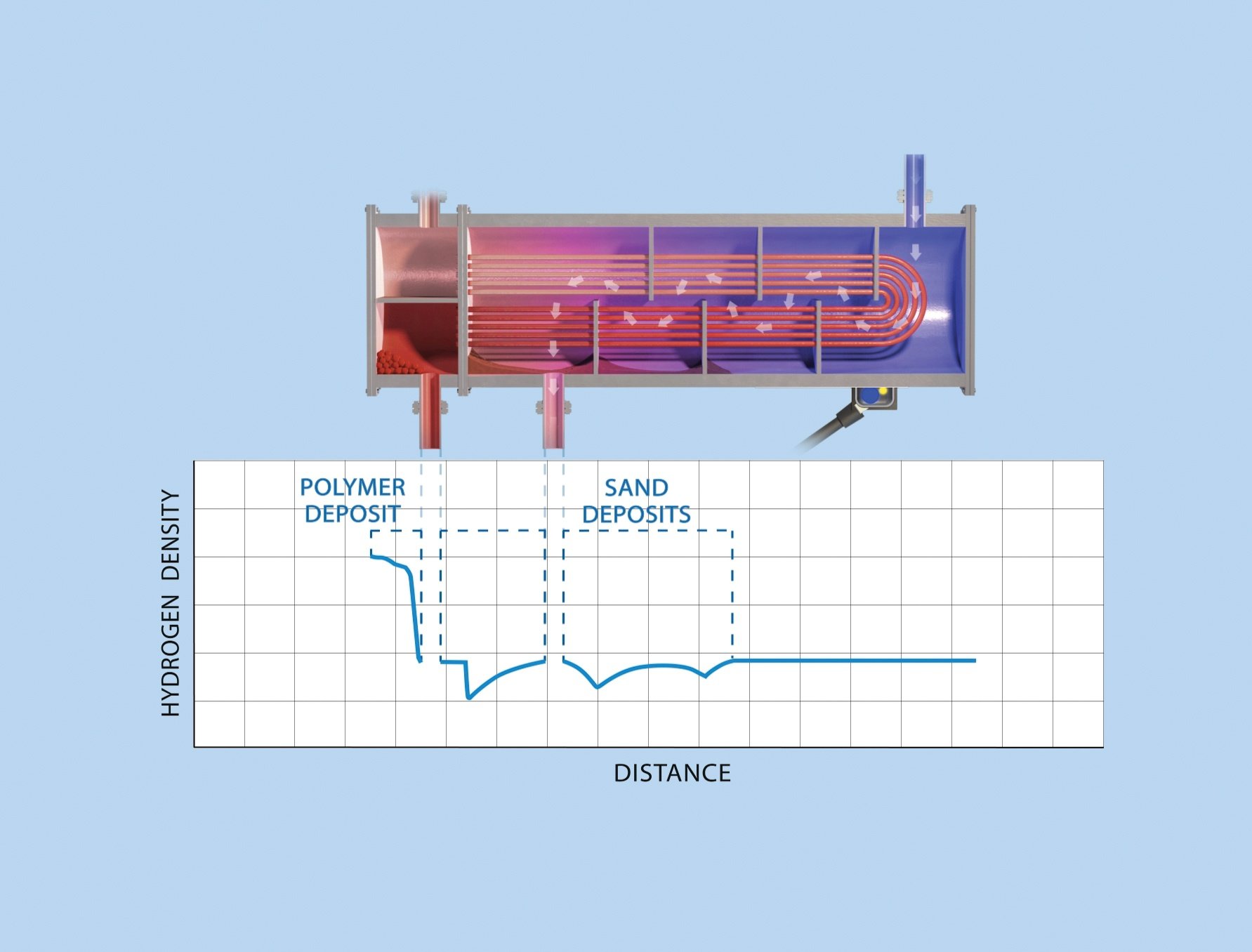

A problem plaguing butadiene purification unit operations is the potential for free radical polymerisation, commonly known as popcorn polymer. This popcorn polymer formation can disrupt the operation of the unit by plugging lines, sticking valves, and even physically damaging equipment. Under certain conditions the polymer growth can push apart flanges, rupture lines and even pop the head off exchangers.