For the first time in the United States, our proprietary chemical tracer technology has been applied to a Carbon Capture and Storage (CCS) project. This achievement strengthens the way operators monitor CO₂ injection and containment, offering independent verification that underground storage remains safe and permanent.

Advancing carbon capture: Our tracer technology in the first US CCS project

Posted by Nurhazirah MY

Sep 26, 2025 10:07:02 AM

Topics: chemical tracers, tracers, chemical tracer technology, Carbon capture and storage, CCUS, CCS

How chemical tracer technology helps drilling engineers get more from the reservoir

Posted by Nurhazirah MY

Sep 25, 2025 5:08:29 AM

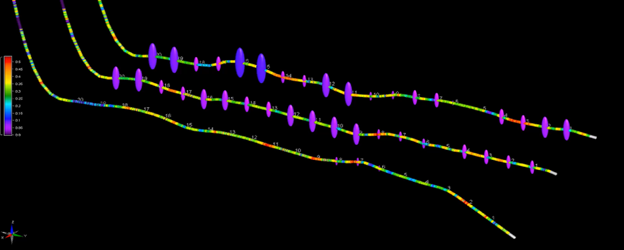

In the oil and gas industry, getting the most out of every reservoir is more important than ever. Drilling engineers are expected to improve performance, manage costs, and reduce risk all while making faster, better decisions in the field. To do that, they need more than good planning and the latest oil tools. They need the right data.

Topics: reservoir characterisation, fluid inflow, reservoir production modeling, tracers

Overcoming flare system integrity challenges with advanced leak detection

Posted by Nurhazirah MY

Apr 15, 2025 5:11:46 AM

High hydrogen sulphide (H2S) concentrations in flare systemspose significant operational and safety risks. To mitigate these risks, Tracerco conducted an advanced leak detection assessment on nine pressure safety valves (PSVs) within the Flare Header. The goal was to enhance safety, ensure regulatory compliance, and improve overall process efficiency using cutting-edge tracer technology and leak detection methodologies.

Topics: Gamma Scanning, tracers, Tru-Scan, leak tests, gamma ray inspection, flare system tracers, excessive flare flow, leak detection, increase production rates, optimising oil and gas production, oil processing, gas processing

Leak testing of pressure safety valves (PSVs) on a flare system

Posted by Nurhazirah MY

Mar 19, 2025 7:55:16 AM

Understanding the significance of flaring in offshore, refinery, and petrochemical operations

Flaring has long been an integral part of offshore oil and gas, refinery, and petrochemical operations, serving as a critical safety mechanism to manage excess gas. However, with increasing environmental regulations and economic pressures, operators are scrutinising their flaring practices to minimise emissions and maximise efficiency..

Topics: Gamma Scanning, tracers, Tru-Scan, leak tests, gamma ray inspection, flare system tracers, excessive flare flow, leak detection, increase production rates, optimising oil and gas production, oil processing, gas processing

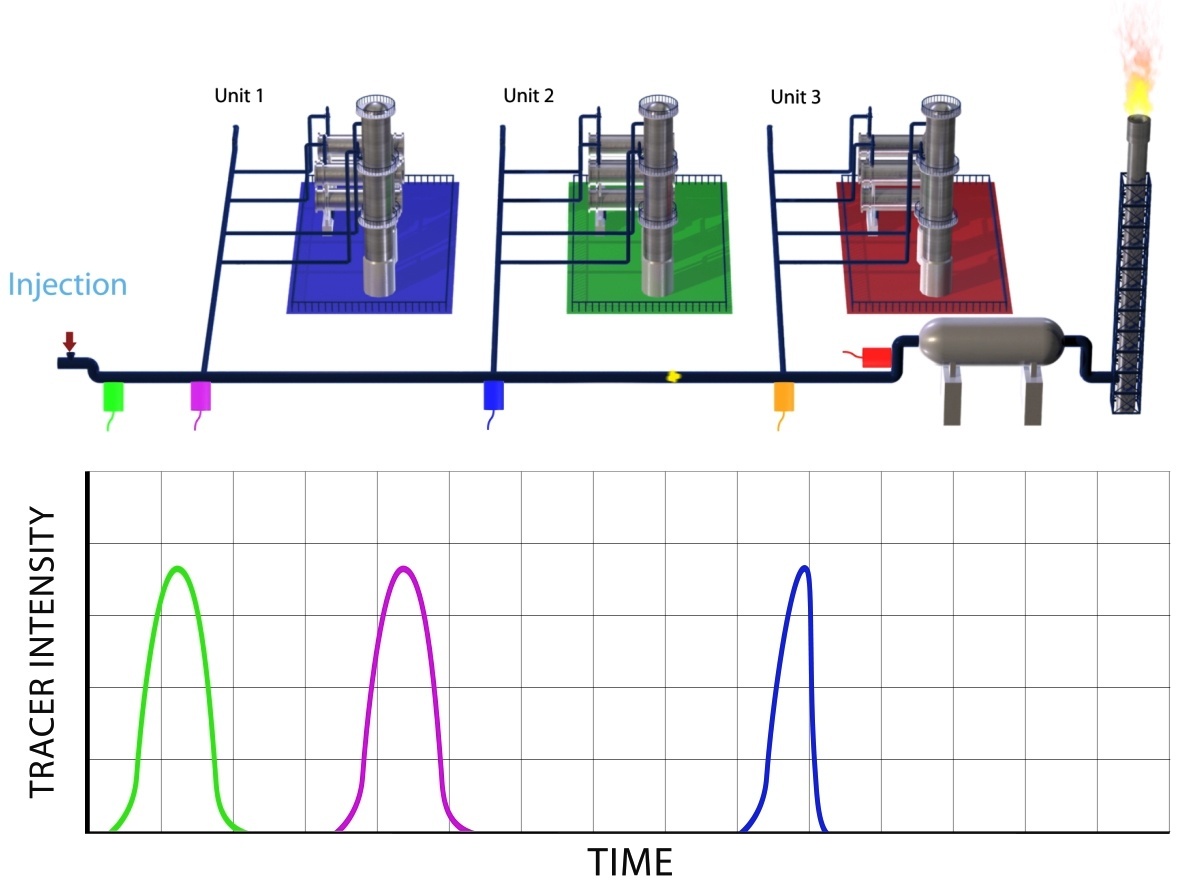

In January 2025, Tracerco partnered with World Oil to host a webinar on the latest innovative advancements in tracer technology for reservoir management. As part of the session, industry leaders shared insights on how low-risk, non-intrusive chemical tracer technology is reshaping the approach to phase production and well communication. Here’s a breakdown of the top 3 questions discussed during the Q&A section of the event:

Topics: Flow assurance, reservoir analysis, reservoir characterisation, tracers, well communication, chemical tracer technology, inflow tracer

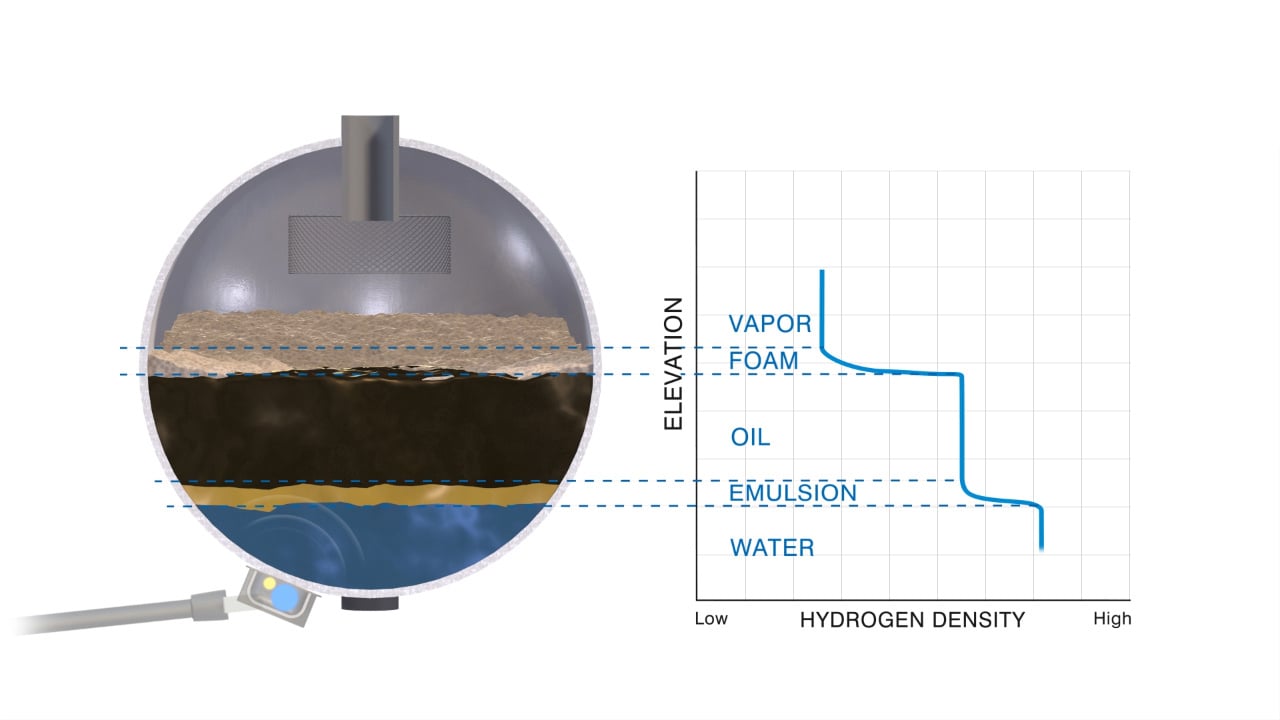

Optimising oil and gas production with advanced scanning and tracer technology

Posted by Nicola Porter

Mar 10, 2025 10:40:42 AM

In the high-stakes world of oil and gas production, every second counts. A minor disruption in operations can have a domino effect, leading to significant financial losses.

Topics: neutron backscatter, Gamma Scanning, tracers, Tru-Scan, gamma ray inspection, oil production, PhaseFinder, separator study, oil in water, water production, oil residence time test, increase production rates, optimising oil and gas production, gas undercutting, oil processing, gas processing, separator systems, liquid carry-over, hydrocarbon separation train

How to save money and gain critical insights with inflow tracer technology

Posted by Nicola Porter

Oct 6, 2021 3:59:31 PM

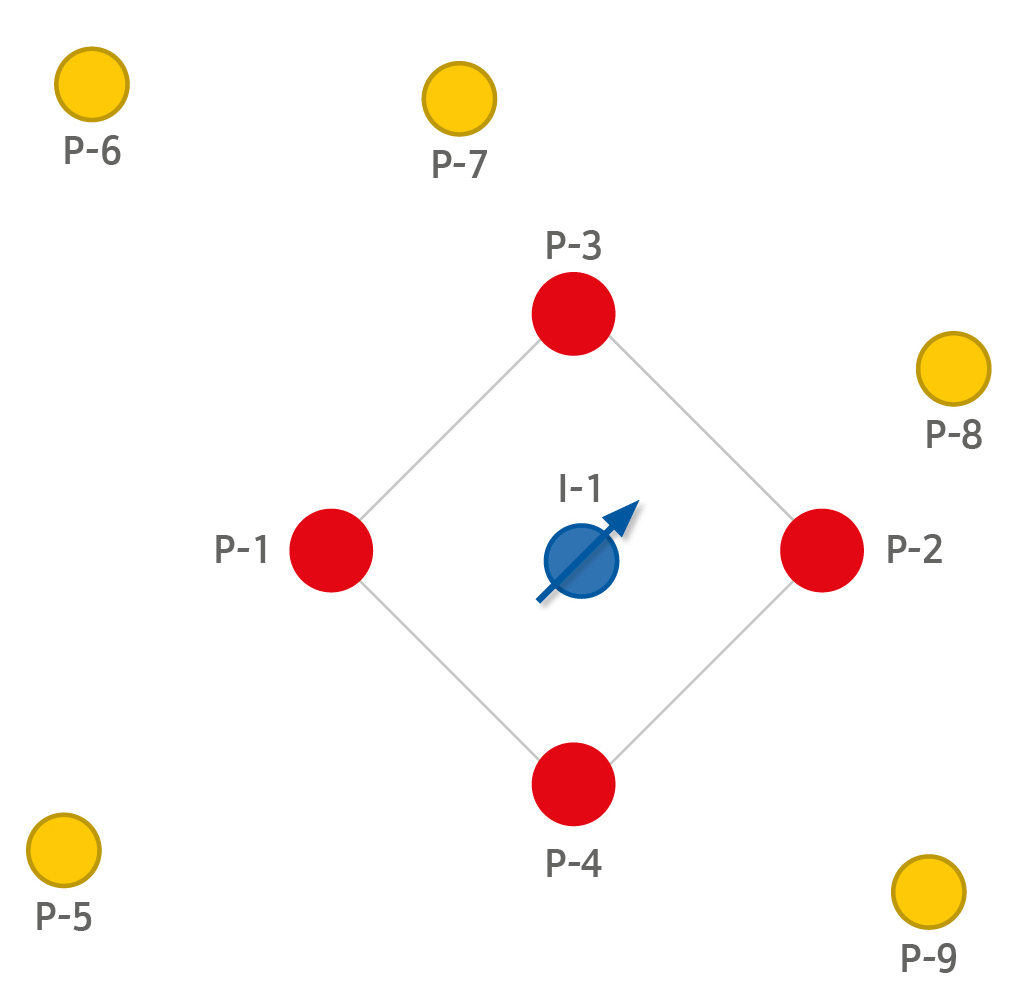

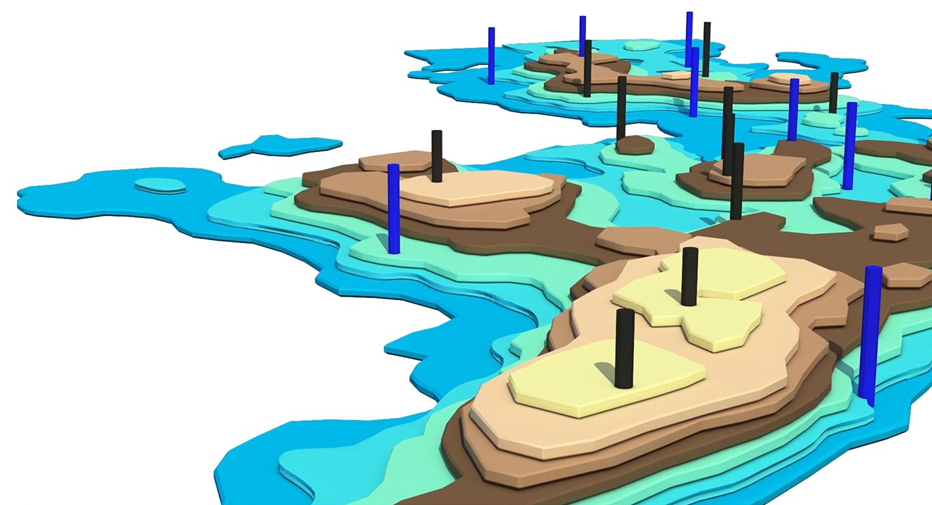

Oil, gas and water-based chemical tracers provide a true understanding of reservoir fluid flow pathways. It helps oil companies continuously monitor their reservoir and optimise drilling, completion and oil development strategies to maximise oil production.

In this blog we will discuss using a case study example, how our range of specialist chemical tracers can provide operators with critical insights without the need for well intervention or deferred production which can result in significant savings.

Topics: chemical tracers, reservoir, interwell, reservoir characterisation, fluid inflow, tracers, oil inflow, water inflow, inflow measurement, inflow, waterflood, injected water, water breakthrough, water production, water tracer, chemical tracer technology, wellbore, mature offshore field, waterflood injection, residual oil saturation, polymer tracer technology, reservoir fluid inflow, inflow tracer

Optimise oil production using inflow, interwell and completion integrity tracers

Posted by Nicola Porter

Mar 22, 2021 4:01:23 PM

Mature oilfields are often characterised by increased water production. This results in costly water treatment and reduced oil processing capacity. Unwanted produced water may stem from well integrity failure, wellbore tortuosity, high waterflood injection rates, high permeability channelling, thief zones or injector / producer well spacing as well as water coning. Identifying the source of excessive water production and mitigating for its costly impact is critical during field development in reducing costs and maximising oil production.

Topics: chemical tracers, reservoir, interwell, reservoir characterisation, fluid inflow, tracers, oil inflow, water inflow, inflow measurement, inflow, waterflood, injected water, water breakthrough, water production, wellbore, mature offshore field, waterflood injection

Interwell partitioning tracers to measure the effectiveness of a chemical EOR flood

Posted by Nicola Porter

Mar 17, 2021 12:57:25 PM

Tracer technology is proven to be critical to assess remaining oil saturation measurement in a reservoir following secondary recovery. It allows the measurement of remaining oil saturation between wells, rather than just surrounding a wellbore. This technique is normally used before and after an Enhanced Oil Recovery (EOR) project to establish changes in crude oil saturation.

In this blog we will discuss using a case study example, how our range of specialist chemical tracers can allow operators to identify the amount of remaining oil saturation in a mature waterflood and determine the effectiveness of specific enhanced oil recovery techniques at reducing remaining oil to residual levels.

Topics: chemical tracers, reservoir, interwell, reservoir characterisation, fluid inflow, tracers, oil inflow, water inflow, inflow measurement, inflow, waterflood, injected water, water breakthrough, water production, water tracer, chemical tracer technology, wellbore, mature offshore field, waterflood injection, residual oil saturation, remaining oil saturation

The top five questions we are asked about a Tracerco™ Interwell Study

Posted by Tracerco

Feb 2, 2018 12:59:59 PM

In this blog post we will highlight and discuss, the top five questions we are asked about a Tracerco™ Interwell Study.

Topics: chemical tracers, reservoir, reservoir analysis, interwell, reservoir characterisation, tracers, smart tracers, tracer technology, well development

Oil and Gas Comment and News

Tracerco's news and comment on measurement and diagnostics in Oil & Gas and processing industries

Tracerco brings comment, news, how tos and more on their blog. Sign up for regular notifications of new posts.

Subscribe to Email Updates

Recent Posts

Posts by Topic

- people (18)

- reservoir (18)

- employee recognition (17)

- reservoir characterisation (17)

- Gamma Scanning (16)

- Life at Tracerco (16)

- chemical tracers (16)

- Flow assurance (15)

- Tru-Scan (15)

- Working Lives (15)

- gamma scan (15)

- pipeline inspection (15)

- Colleague Forum (14)

- Discovery (14)

- Process Diagnostics (14)

- pipeline integrity (14)

- tracers (14)

- Subsea Technology (13)

- subsea flowlines (12)

- Asset Integrity (9)

- subsea pipelines (9)

- Explorer (8)

- Subsea Inspection (8)

- Subsea Integrity (8)

- Tru-Grid Scan (8)

- liquid distribution (8)

- nucleonic instrumentation (8)

- Awards (7)

- PackView Analysis (7)

- fluid inflow (7)

- optimising plant processing (7)

- packed bed towers (7)

- quantitative analysis pack beds (7)

- reservoir analysis (7)

- unconventional wells (7)

- Distillation Column Performance (6)

- Liquid maldistribution (6)

- Process Diagnostics Technology (6)

- Suspected maldistribution in packed beds (6)

- desalter optimization (6)

- excessive flare flow (6)

- flare system tracers (6)

- fracking (6)

- interwell (6)

- packed column (6)

- pipe in pipe (6)

- pipeline blockage (6)

- pipeline life extension (6)

- process diagnostics technologies (6)

- tracer technology (6)

- CT scanner (5)

- Separator (5)

- Subsea flexibles (5)

- Tracer Study (5)

- Tracerco Profiler (5)

- Tracerco innovations (5)

- distillation column maintenance (5)

- gamma scanning distillation columns (5)

- inflow measurement (5)

- packed bed performance analytics (5)

- packed bed scan (5)

- pipe bundles (5)

- pipeline extension (5)

- plant processing (5)

- radiation monitor (5)

- smart tracers (5)

- tracerco diagnostics (5)

- tray fouling (5)

- water inflow (5)

- CT scanning (4)

- NORM (4)

- NORM Management (4)

- Subsea Technologies (4)

- chemical leak test (4)

- chemical tracer technology (4)

- density of liquid (4)

- fcc diagnostics (4)

- fcc troubleshooting (4)

- fcc unit process (4)

- fccu studies (4)

- feed/effluent heat exchangers (4)

- fluid catalytic cracking unit (4)

- fugitive flare flow (4)

- gulf of mexico (4)

- hydrocarbon separation train (4)

- instrumentation (4)

- instrumentation control (4)

- multiphase separation (4)

- north sea (4)

- nucleonic instrument (4)

- oil inflow (4)

- online leak detection (4)

- process control (4)

- radiation (4)

- scanning technology (4)

- tower gamma scan (4)

- tower scanning (4)

- trayed tower (4)

- unconventional oil and gas (4)

- water production (4)

- Column Performance (3)

- Decommissioning (3)

- Downstream (3)

- Flow Study (3)

- Flowlines (3)

- FrothView (3)

- NORM Detection (3)

- Naturally Occurring Radioactive Material (3)

- Packed Beds (3)

- Radiation Protection (3)

- Radiation Protection Adviser (3)

- Tray Damage (3)

- adulterated fuel (3)

- brand authentication (3)

- brand protection (3)

- brand security (3)

- catalyst bed wash (3)

- consumer protection (3)

- controlled release (3)

- counterfeit detection (3)

- delayed coke drum (3)

- desalting (3)

- distillation column (3)

- distillation column scan (3)

- distillation column scanning (3)

- distillation tower scanning (3)

- enhanced interface control (3)

- exchanger bundle leak testing (3)

- fcc cracking (3)

- fcc services (3)

- fcc unit (3)

- fiscal tax recovery (3)

- flare flow (3)

- flare gas flow measurement (3)

- flare gas flow meter (3)

- flare study (3)

- fluid catalytic cracking diagnostics (3)

- fluid catalytic cracking services (3)

- frac wells (3)

- gamma ray inspection (3)

- gas processing (3)

- increase production rates (3)

- increased separator efficiencies (3)

- inflow (3)

- injected water (3)

- leak detection (3)

- leak tests (3)

- manage turnaround costs (3)

- mature offshore field (3)

- monitor wash bed coking (3)

- neutron backscatter (3)

- nucleonic technology (3)

- off spec product (3)

- oil & gas (3)

- oil processing (3)

- optimising oil and gas production (3)

- optimising plant production (3)

- packed column performance (3)

- packing mal-distribution (3)

- ped (3)

- personal electronic dosimeter (3)

- process condition monitoring (3)

- process systems (3)

- product quality (3)

- profiler (3)

- radiation detection (3)

- radiation safety (3)

- revenue protection (3)

- separator performance (3)

- technology enabling cost savings (3)

- tomography scan (3)

- tower scan (3)

- trayed columns (3)

- turnaround critical path project (3)

- turnaround planning (3)

- turnaround schedules (3)

- turnarounds (3)

- verify flow meters (3)

- water breakthrough (3)

- waterflood (3)

- waterflood injection (3)

- well development (3)

- wellbore (3)

- Catalytic cracking (2)

- Damage to vessel internals (2)

- Depropanizer scan tray damage (2)

- Engineering (2)

- Events (2)

- Flooded Memeber Inspection (2)

- Flow distribution (2)

- High temperature plant processing (2)

- Houston events (2)

- INWED22 (2)

- Imagine the Future (2)

- International Women in Engineering Day (2)

- Inventors and Innovators (2)

- Level+ (2)

- Maths (2)

- PhaseFinder (2)

- Radiation Waste Adviser (2)

- SAGD (2)

- SRU Unit (2)

- STEM (2)

- Science (2)

- Subsea (2)

- Sulphur Recovery Unit (2)

- TENORM (2)

- Technology (2)

- ThruVision scan (2)

- Tracerco technologies (2)

- Tray Capacity (2)

- Upstream (2)

- Women in STEM (2)

- Women in engineering (2)

- annular liquid distribution (2)

- area monitoring (2)

- authentication (2)

- baseline scan (2)

- brand protection technology (2)

- coke (2)

- coke buildup (2)

- coke deposits (2)

- coke drum (2)

- coke drum cycle (2)

- coke drum optimization (2)

- coker optimization (2)

- column troubleshooting (2)

- counterfeiting (2)

- cracking unit (2)

- desalter (2)

- dose rate (2)

- dosimeter (2)

- drilling (2)

- employees (2)

- exchanger (2)

- fcc (2)

- fcc process (2)

- fcc riser (2)

- fcc units (2)

- fccu process (2)

- fccu unit refinery (2)

- fixed monitoring (2)

- flare flow measurement (2)

- flare flow meter (2)

- flare flowrate data (2)

- flare gas meter (2)

- flare gas meters (2)

- flare lines (2)

- flare measurement (2)

- flooded trays (2)

- flow profiling (2)

- flow rate calculations (2)

- flowrate (2)

- fouling (2)

- fouling deposits (2)

- fuel fraud (2)

- gas flow meter proving (2)

- gas meter proving techniques (2)

- grout monitoring (2)

- inflow tracer (2)

- insights (2)

- leaking exchangers (2)

- level detection devices (2)

- liquid restriction (2)

- marketing (2)

- mechanical integrity (2)

- monitoring (2)

- monitors (2)

- observa (2)

- oil in water (2)

- oil production (2)

- pigging (2)

- pre-turnaround scans (2)

- process diagnostics systems (2)

- process equipment (2)

- process vessels (2)

- product authentication (2)

- product protection (2)

- reservoir production modeling (2)

- residual oil saturation (2)

- safeguard brand equity (2)

- safeguard brand quality (2)

- safety (2)

- safety awareness (2)

- safety stand-down (2)

- separator study (2)

- shale (2)

- shale production (2)

- small leaks (2)

- solids buildup (2)

- stuck pig (2)

- tracer analysis (2)

- water tracer (2)

- well communication (2)

- work safe home safe (2)

- workplace safety (2)

- Ammonia converter (1)

- Be Safe (1)

- Blockages in perforated plates (1)

- CCS (1)

- CCUS (1)

- CDU (1)

- Carbon capture and storage (1)

- Carryover (1)

- Column Flooding (1)

- Demulsifier Chemical (1)

- Digital Marketing (1)

- EHS (1)

- EHS behaviour (1)

- EHS culture (1)

- EPD (1)

- Entrainment (1)

- FCCU (1)

- FMD (1)

- FMI (1)

- Global exchange (1)

- H2S Absorber (1)

- Heavy oil (1)

- InDepth (1)

- Intercat (1)

- Life cycle management (1)

- NORM Monitor-IS (1)

- NORM Survey Meters (1)

- OTC (1)

- PSV (1)

- Physics (1)

- Platform Members (1)

- Platform Memeber Integrity (1)

- Platform Structural Members (1)

- ROV-deployed instrumentation (1)

- SEO (1)

- Suspected maldistribution (1)

- ThruVision (1)

- Tracerco Day (1)

- Tray weeping (1)

- Water Ingress (1)

- Weeping (1)

- activities (1)

- adulteration (1)

- authentication solutions (1)

- authentication, product authentication (1)

- beer column (1)

- brand (1)

- brand protection tehnology (1)

- butadiene condenser (1)

- butadiene purification unit (1)

- calibrate flow meters (1)

- catalyst loss (1)

- celebration (1)

- coker units (1)

- counterfeit fuel (1)

- critical path (1)

- critical path planning (1)

- crude distillation unit (1)

- crude unit (1)

- crude vacuum tower (1)

- debutanizer (1)

- desalter maldistribution (1)

- desalter performance (1)

- distillation column service (1)

- distillation tower scan (1)

- distribution study (1)

- education (1)

- electronic personal dosimeter (1)

- environmental reporting (1)

- exchangers (1)

- extraction tower (1)

- fcc addition systems (1)

- fcc additives (1)

- fcc reactor (1)

- flare gas measurement (1)

- foam profile (1)

- fouled trays (1)

- fouling accumulation (1)

- fracture diagnostics (1)

- fuel adulteration (1)

- fuel marker (1)

- fuel marker technology (1)

- fuel marking (1)

- fuel smuggling (1)

- fugitive emissions (1)

- gamma ray inspection distillation (1)

- gamma scan distillationcolumns (1)

- gammatrac (1)

- gas flow meter prover (1)

- gas plant (1)

- gas undercutting (1)

- grout compliance (1)

- grout density monitoring (1)

- grout quality (1)

- health and safety (1)

- heat exchanger (1)

- heat exchangers (1)

- interface levels (1)

- leak study (1)

- leak testing (1)

- leaking pressure safety valve (1)

- leaking psv (1)

- liquid carry-over (1)

- liquid liquid extractor (1)

- marker systems (1)

- mass transfer diagnostics (1)

- medical (1)

- mental wellbeing (1)

- mobile tracer labs (1)

- monopile and jacket foundations (1)

- new technology (1)

- oil residence time test (1)

- outdoor fun (1)

- personal dosimetry (1)

- pig run (1)

- pig tracking (1)

- pig tracking services (1)

- plant performance (1)

- polymer tracer technology (1)

- polymerisation (1)

- popcorn polymer (1)

- pre-turnaround planning (1)

- pressure safety valve (1)

- process optimisation (1)

- process pipes (1)

- product assurance (1)

- providing insight onsite (1)

- radioactive source security (1)

- radiography (1)

- reactor cyclone (1)

- reactor distributor (1)

- reactor riser (1)

- reactor stripper (1)

- real-time density profiling (1)

- real-time insights (1)

- real-time measurement (1)

- refining (1)

- refractory depth (1)

- refractory lined pipes (1)

- refractory lined vessels (1)

- refractory loss (1)

- refractory measurements (1)

- regenerator cyclone (1)

- remaining oil saturation (1)

- reservoir fluid inflow (1)

- reservoir stimulation (1)

- responsive design (1)

- riser reactor (1)

- risers (1)

- safety behaviour (1)

- safety culture (1)

- safety education (1)

- separation tower scanning (1)

- separator systems (1)

- shutdown planning (1)

- shutdowns (1)

- source security (1)

- source theft (1)

- tower performance (1)

- trayed extraction tower (1)

- wash bed optimization (1)