In this blog post we will highlight and discuss, the top five questions we are asked about a Tracerco™ Interwell Study.

1. What is a Tracerco™ Interwell Study? Why should you add it to your reservoir surveillance toolbox?

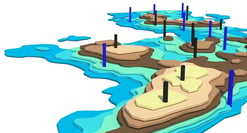

A Tracerco™ Interwell study enables interwell flow measurement of injected water, gas, steam and enhanced oil recovery chemicals. By injecting a range of specialised chemical tracers into both new field developments and mature reservoirs, operators can determine how their field is connected. They can also measure the presence of high permeability channels, provide flow trends, prove where barriers to flow and fault lines exist, and ultimately assess the effectiveness of EOR studies to optimise and maximise development plans.

2. Where is Interwell tracing used? Is it primarily still in use for conventional wells?

Interwell tracing is used in both conventional and unconventional fields for different reasons. In the case of conventional fields, it is used to better determine communication pathways and quantify flow volumetrics. In the case of unconventional reservoirs interwell tracing is used to optimize well spacing by measuring cross well communications from each stage. Tracerco has other tracer technologies that are used in unconventional reservoirs to quantify relative stage flow back for gas, water and oil.

3. What do you see as an ideal plan for green field development?

In a green field development, tracers can really help in determining fluid flows and confirm faults and layers that are present in the reservoir. It is therefore worthwhile using tracers from the onset of the project. Furthermore, tracers can be built-up in an inflow horizontal well to understand the flow distribution from different places in a horizontal well and differentiate between injection and connate water breakthrough. If scale may be of issue to a project, an additional benefit of using tracers at the beginning of the flood process is that it provides an early warning of injected water breakthrough, so that an effective scale inhibition program can be initiated well in advance of significant ion change.

4. How does the reservoir heterogeneity of the reservoir affect the time of tracer injection and sample frequency?

Reservoir heterogeneity does not make a huge amount of difference on the injection timing unless breakthrough is within hours (in which case a very short injection time is needed). It is important to consider heterogeneity / fracture presence / channelling when planning a sampling strategy so that fast breakthrough profiles are not missed. This is carried out as part of project design. If we suspect fast breakthrough due to heterogeneity, then we would normally sample very frequently at the beginning of a project and would subsequently reduce frequency as time moves forward and tracer is dispersed.

5. What additional challenges must be handled when dealing with horizontal injection wells?

Horizontal well projects generally work in the same manner as a vertical well. The pore volumetrics may be a little different when designing the project, due to the potential for water injected along the whole length of the wellbore but apart from this aspect, very little is different to a vertical well design. If the water injection well has isolation due to smart well completions, it is possible to inject different tracers into each horizontal well compartment in order to determine sweep from each position. It is also possible to combine interwell tracers with inflow tracers in horizontal injectors and producers. This allows both interwell pore volume sweep to be determined and position of entry into a well to be established through analysis of water samples for both tracer types.

Watch our webcast "Well-to-well tracer tests for reservoir characterisation and measurement of EOR effectiveness" to learn more about how a Tracerco™ Interwell Study can allow you to optimise field development plans and increase reservoir production.