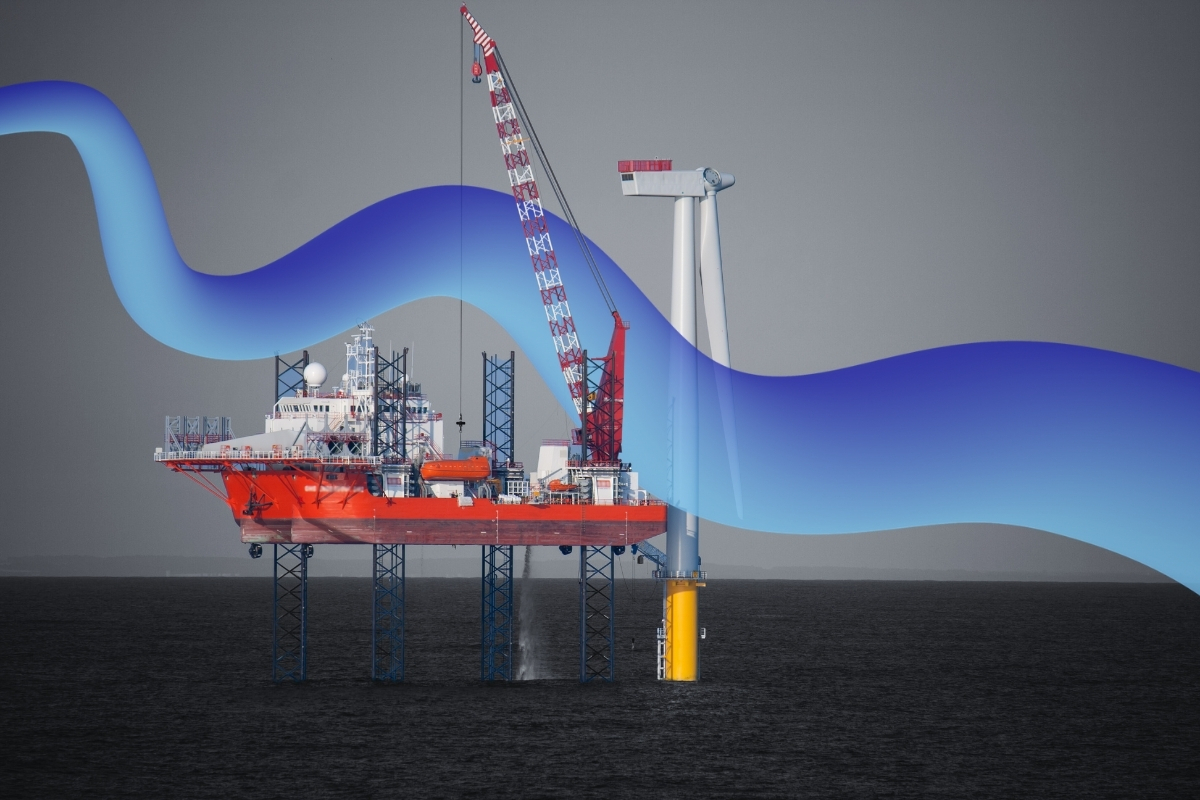

Offshore sector in Asia is entering an exciting phase. Deepwater oil and gas remain crucial, while offshore wind is rising as countries push for cleaner, independent energy.

As activity grows in both areas, operators are looking for better ways to ensure asset integrity and efficient operations. Successful completion of two major subsea projects in Southeast Asia demonstrating how Tracerco's technologies support both traditional and renewable energy markets.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Asset Integrity,

subsea pipelines,

Subsea Inspection,

Subsea Integrity,

pipeline life extension,

pipeline extension,

CT scanner,

grout monitoring

Maintaining offshore pipeline integrity

In the evolving world of offshore oil and gas, maintaining subsea pipeline integrity is not just important. It is essential for safety, efficiency, and long-term operational success. However, traditional pipeline inspection methods often struggle in the high-pressure, deepwater conditions typical of modern offshore fields.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Explorer,

Asset Integrity,

Subsea flexibles,

subsea pipelines,

pipeline blockage,

Subsea Inspection,

Subsea Integrity,

pipeline life extension,

pipeline extension,

CT scanner,

CT scanning,

gulf of mexico,

north sea

In the ever-evolving offshore energy sector, the integrity of subsea pipelines remains a fundamental priority and a growing challenge. As operations venture into deeper and harsher environments, maintaining pipeline health over its full lifecycle has become increasingly complex. With risks such as corrosion, flow restrictions, and limited inspection access threatening both performance and safety, operators are turning to smarter, more proactive methods to manage these subsea assets.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Explorer,

Asset Integrity,

Subsea flexibles,

subsea pipelines,

pipeline blockage,

Subsea Inspection,

Subsea Integrity,

pipeline life extension,

pipeline extension,

CT scanner,

CT scanning,

gulf of mexico,

north sea

Keeping operations flowing smoothly

Flow assurance is at the core of offshore and subsea oil and gas operations. Ensuring uninterrupted transportation of hydrocarbons from reservoirs to processing facilities is a fundamental challenge, especially in deepwater environments where extreme pressures and temperatures can cause blockages. As the industry evolves, so too must our approach to diagnosing and preventing these issues.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Explorer,

Asset Integrity,

Subsea flexibles,

subsea pipelines,

pipeline blockage,

Subsea Inspection,

Subsea Integrity,

pipeline life extension,

pipeline extension,

CT scanner,

CT scanning,

gulf of mexico,

north sea

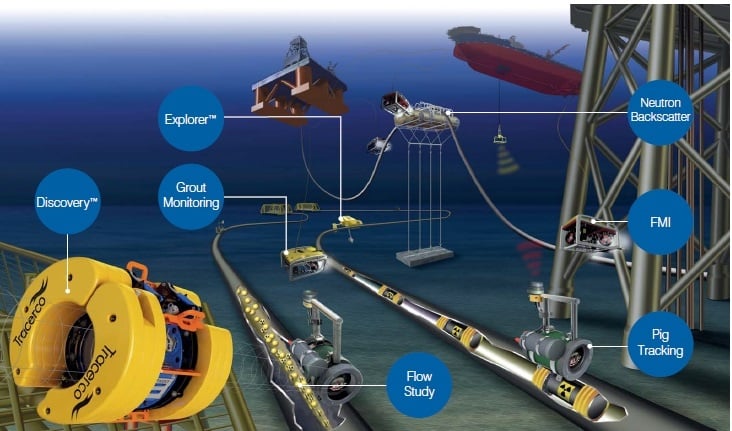

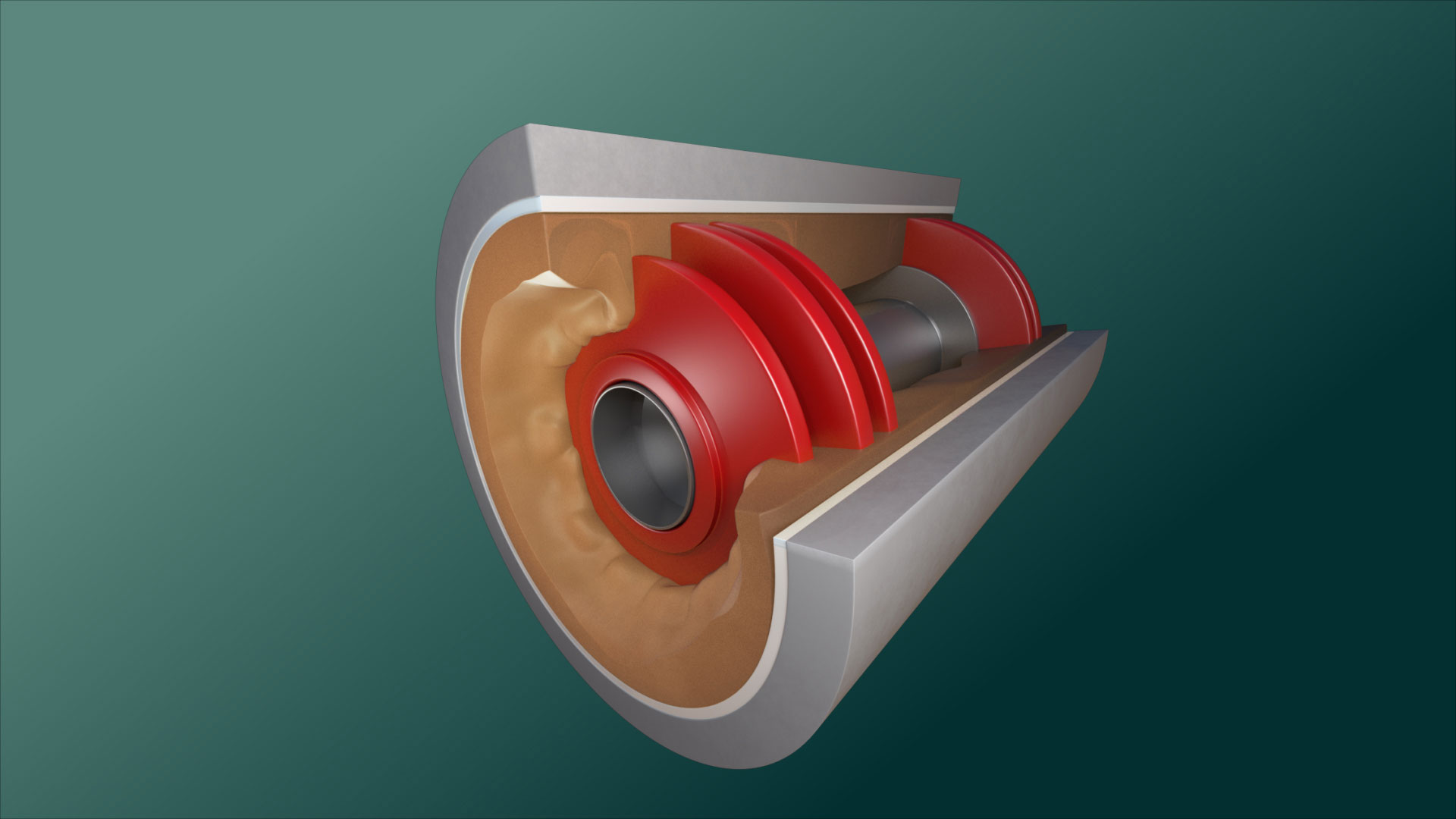

In the demanding realm of subsea oil and gas operations, maintaining pipeline integrity and ensuring optimal performance of pipelines is paramount. At Tracerco our innovative technologies, notably Discovery™ and Explorer™, have set new benchmarks in non-intrusive subsea pipeline inspection. We offer operators unparalleled insights into asset integrity and flow assurance, helping them make informed decisions about their operations without compromising production.

In this blog we discuss how Tracerco can help you gain insight into how operators are leveraging these technologies to their advantage.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Explorer,

Asset Integrity,

Subsea flexibles,

subsea pipelines,

pipeline blockage,

Subsea Inspection,

Subsea Integrity,

pipeline life extension,

pipeline extension,

CT scanner,

CT scanning,

gulf of mexico,

north sea

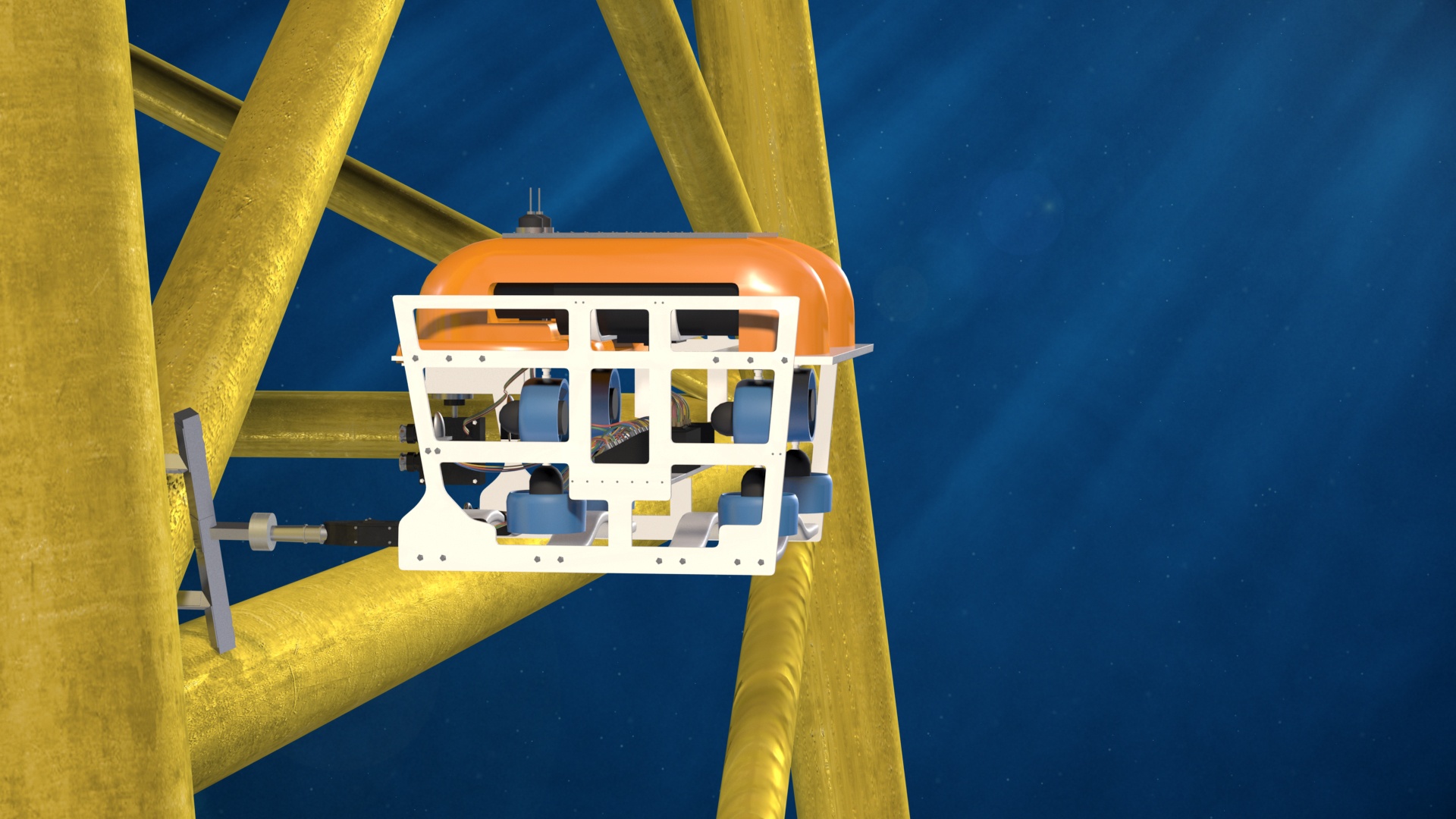

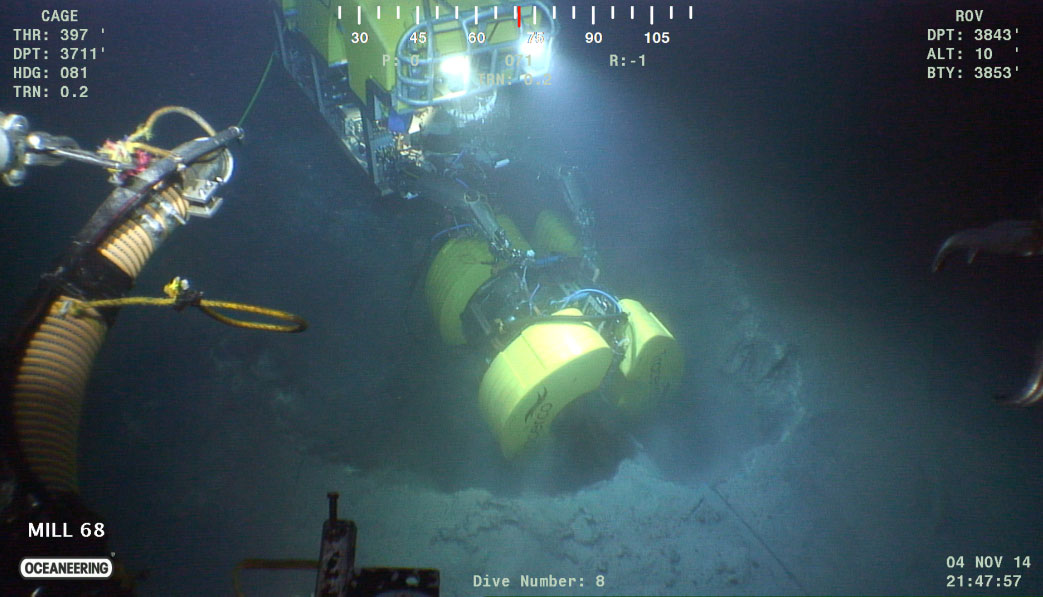

Tracerco Diagnostics™ FMI (Flooded Member Inspection) technology has become the industries number one choice for inspecting platform members for water ingress. Over recent years we have seen reduced time for inspection campaigns in order to meet the new financial demands expected from the Oil and Gas Industry. At Tracerco we continue to put an emphasis on successful initial inspections, ensuring that there are no unnecessary delays. This ensures that inspections are right first time and reduces the risk of far greater financial impact which can be associated with repeat inspections, or remedial work that may not even be required.

The FMI system can measure the degree of water ingress into platform structural members indicative of through wall defects without any need to remove marine growth or specialist coatings. It is operable as a simple attachment to any Remotely Operated Vehicle (ROV) or can be manually deployed by a suitably trained diver. A highly focused beam of gamma radiation and an ultra-sensitive detector unit are mounted on opposite forks of a variable yoke system and positioned across the diameter of the member under inspection. The transmitted radiation intensity is measured and compared to the intensity expected for a dry member based upon the particular member’s diameter, wall thickness and system calibration. Water inside the member will result in a decrease in the expected “dry member” transmitted signal. Each response is evaluated by our bespoke software and trained Offshore Technicians to provide a full report of platform jacket integrity.

Read More

Topics:

Subsea Technology,

Subsea Technologies,

Subsea,

FMI,

FMD,

Flooded Memeber Inspection,

Platform Members,

Platform Memeber Integrity,

Platform Structural Members,

Subsea Inspection,

Subsea Integrity,

Water Ingress

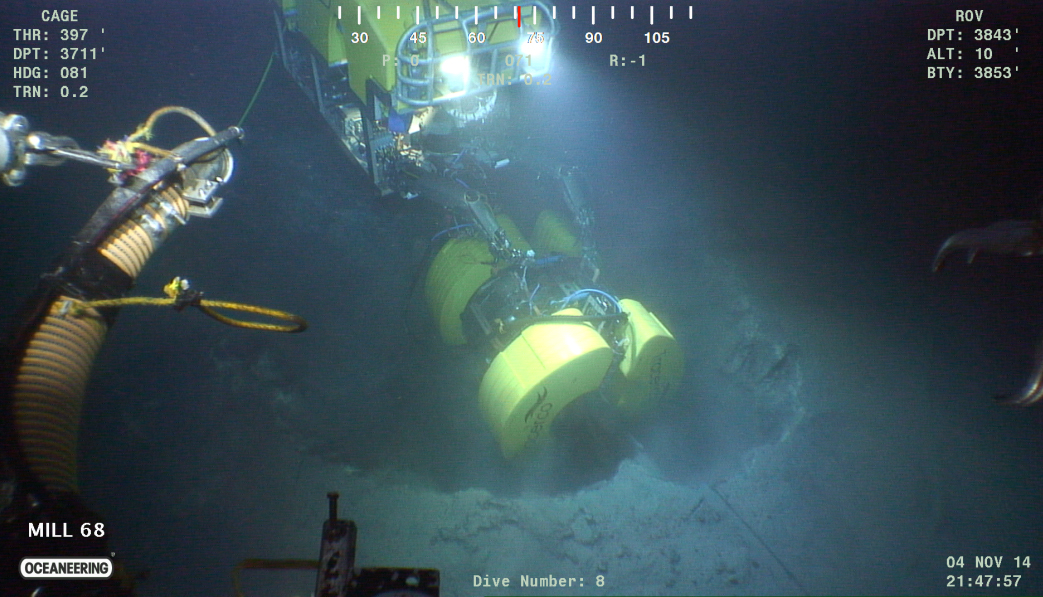

It's a nightmare scenario no one wants... You run a PIG and it becomes stuck in the line. You now have an unsuccessful pigging campaign, a subsea pipeline blockage, and a missing PIG to deal with.

The cost of a shutdown due to a PIG stuck in a subsea pipeline can run into tens of millions in lost production, which is why it is absolutely critical to remedy the situation as quickly as possible. In this post we will examine the first step to remedying a blocked subsea pipeline due to a stuck PIG; that is locating the stuck PIG.

Read More

Topics:

pipeline inspection,

subsea flowlines,

Flow assurance,

Subsea Technology,

pipe bundles,

pipe in pipe,

Explorer,

scanning technology,

Flowlines,

subsea pipelines,

pipeline blockage,

pigging,

stuck pig

Tracerco are exhibiting in two areas at OTC and have a lot of exciting new developments to talk about in Reservoir and Subsea Technologies respectively. Please visit booths 8213 in the NRG Arena or booth 2241L part of the UK pavilion in the NRG center to learn more about these technologies and innovative new developments.

In the mean time we have listed a preview of the top four stories from Tracerco at OTC.

Read More

Topics:

Tracerco innovations,

Discovery,

pipeline inspection,

subsea flowlines,

Flow assurance,

Subsea Technology,

Awards,

chemical tracers,

oil & gas,

reservoir,

controlled release,

flow profiling,

reservoir analysis,

tracer analysis,

interwell,

Explorer,

mobile tracer labs

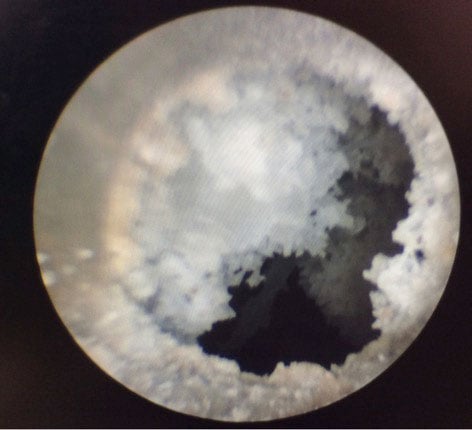

Flow assurance specialists have long faced the challenge of maintaining continuous flow through subsea pipelines. Over time deposits can build-up and can lead to shortfall of revenue through lost production. When these issues occur, they face the problem of determining the exact location and nature of the blockage in order to take action, without risking damage to the subsea pipeline.

In this post we will explain step by step how to pinpoint the exact location of any flow assurance issues including how to investigate them further, determining whether they are hydrate deposits or wax deposits, or indeed distinguishing between asphaltene deposits or scale deposition. All without shutting down production or modifying subsea pipelines in any way.

Read More

Topics:

Discovery,

pipeline inspection,

subsea flowlines,

Flow assurance,

Subsea Technology,

pipe bundles,

pipe in pipe,

Explorer

Last night DiscoveryTM won the Innovation and Technology category at the Subsea UK Awards.This is the second award it has picked up in the last 12 months. As an industry breakthrough in pipeline inspection, diagnosing flow assurance issues as well as pipeline integrity flaws, we give you five reasons why the industry regards it as so unique and special, and how it helps our customers overcome challenges they face.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Awards