Tracerco Insight Vol. 8 Ed. 2 newsletter is now available.

The Tracerco Insight newsletter featuring some of our latest case studies illustrating how Tracerco was able to provide our customers the necessary data that allowed the operations staff to make informed decisions for troubleshooting and optimising their process. Read more to see what's inside the latest issue.

This issue contains the following articles:

- Optimizing Desalter Performance Is Just One of Tracerco's Specialties We Proudly Provide.

- Crude Vacuum Tower Wash Bed Optimization.

- Application Note - ThruVision™

- Manage and Control Your Turnaround Costs to Avoid Possible Surprises.

- New Product Announcement: PED-ER and PED-ER+

Read more on how to download the latest issue.

Read More

Topics:

nucleonic instrumentation,

Tru-Scan,

process diagnostics technologies,

gamma scan,

monitor wash bed coking,

tracer technology,

Tracer Study,

catalyst bed wash,

desalter optimization,

wash bed optimization,

manage turnaround costs,

Depropanizer scan tray damage,

desalter,

Tracerco Profiler,

crude vacuum tower,

turnaround critical path project,

pre-turnaround scans

Flowrate and leak testing applications, pipe scanning and meter proving services are fast, accurate and cost-effective methods to determine the flow of vapour, carryover of liquid, build-up of sludge and fouling materials in piping, as well as the calibration of flow meters.

Read More

Topics:

process systems,

Process Diagnostics,

process diagnostics technologies,

tracerco diagnostics,

flare gas flow meter,

flare gas meter,

gas flow meter proving,

Flow Study,

flowrate,

flare study,

flare flow measurement,

flare system tracers,

gas flow meter prover,

flare flow,

flare gas flow measurement,

excessive flare flow,

flare flow meter,

flare gas measurement,

flare flowrate data,

flare lines,

Process Diagnostics Technology,

process diagnostics systems,

flare measurement,

flare gas meters,

gas meter proving techniques

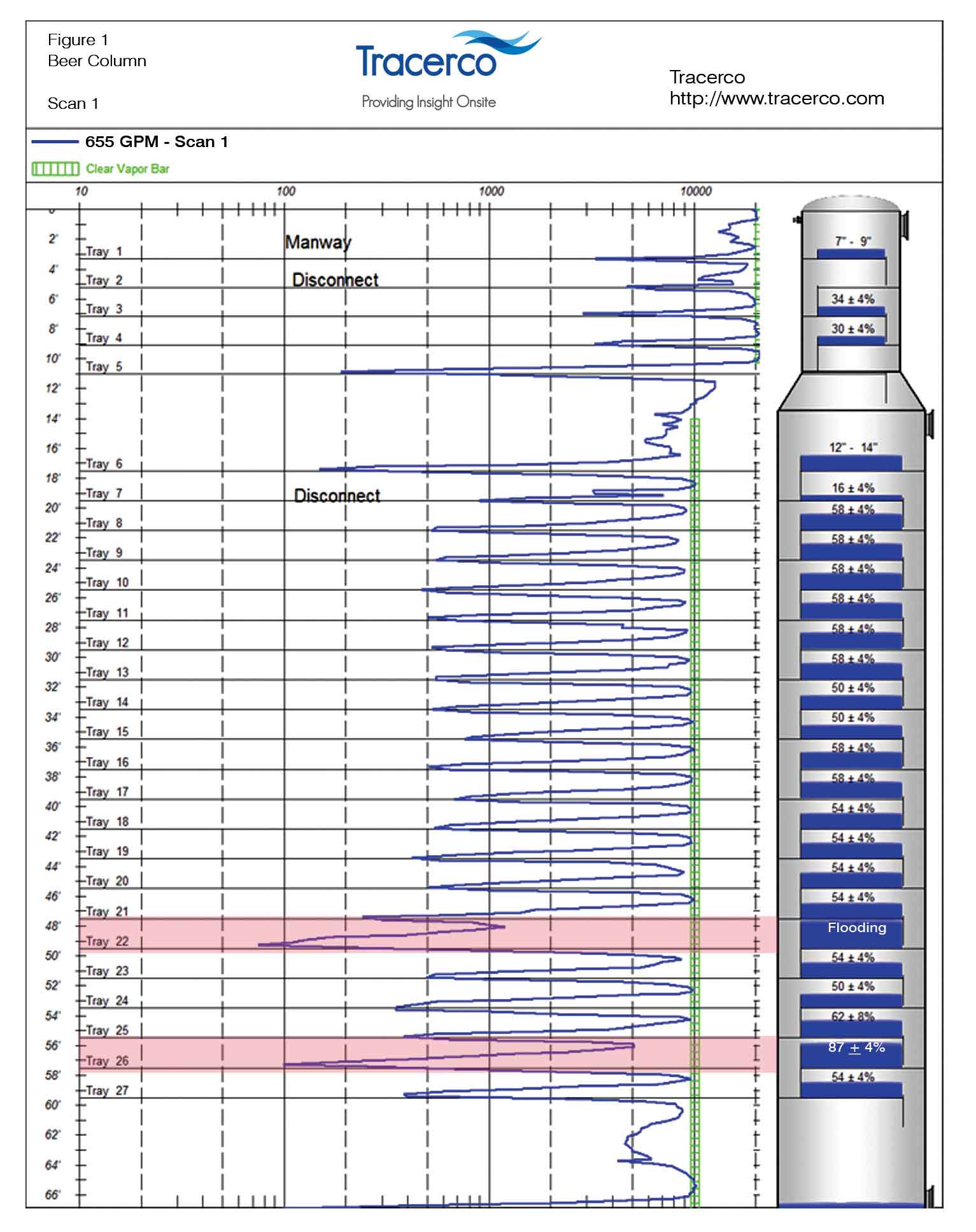

Scanning technology can provide a valuable insight when critical process equipment is experiencing problems and producing off-spec product. Based on the results provided, the best course of action to correct the problem can be identified in the least amount of time in order to save valuable process system downtime.

Read More

Topics:

Process Diagnostics,

Tru-Scan,

Tray Damage,

tower scan,

process diagnostics technologies,

tower scanning,

trayed columns,

flooded trays,

beer column,

process equipment,

fouled trays,

Process Diagnostics Technology,

process diagnostics systems,

tray fouling,

mechanical integrity

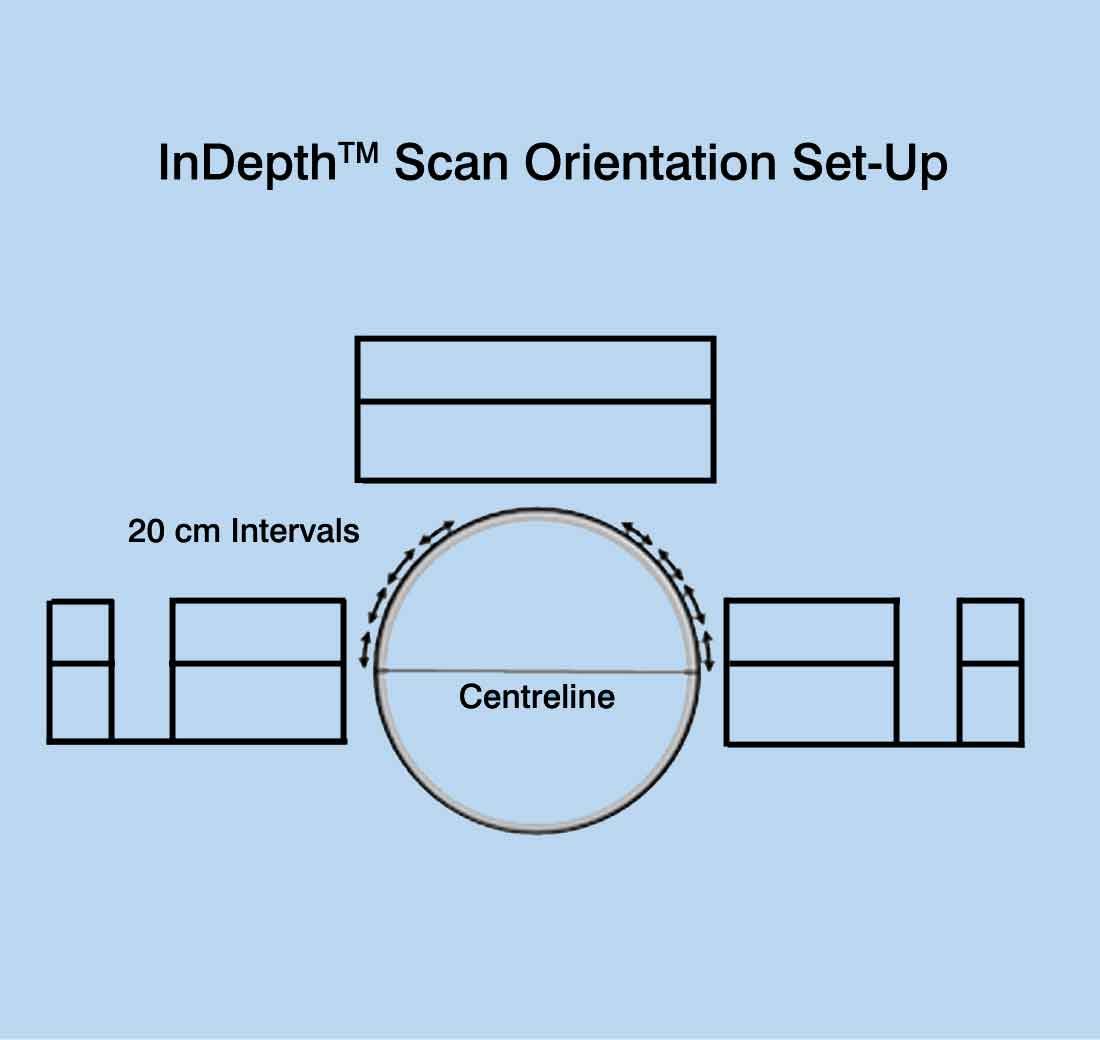

Every refinery invests a tremendous amount of time and money in planning a unit turnaround. Scheduling of the tasks, manpower and equipment has to be detailed and thorough. In order to plan, information is needed about the process system so that critical tasks can be planned to meet turnaround time constraints. Some of this condition-based information is gathered using tools such as gamma scans, radiography, ultrasonic probes, vibration monitors, acoustic sensors, and other non-destructive techniques whilst the process is still operating. It is vital to be aware of any internal damage to distillation columns, heat exchangers, reactors, and other vessels to avoid surprises that can disrupt the turnaround schedule. Each day of downtime is a day of lost production, so it is critical that a turnaround is not extended due to unexpected repair work.

Read More

Topics:

process vessels,

Process Diagnostics,

process diagnostics technologies,

tracerco diagnostics,

refractory depth,

shutdown planning,

refractory loss,

process pipes,

coke buildup,

InDepth,

turnaround schedules,

refractory measurements,

shutdowns,

turnarounds,

refractory lined pipes,

coke deposits,

Process Diagnostics Technology,

turnaround planning,

refractory lined vessels

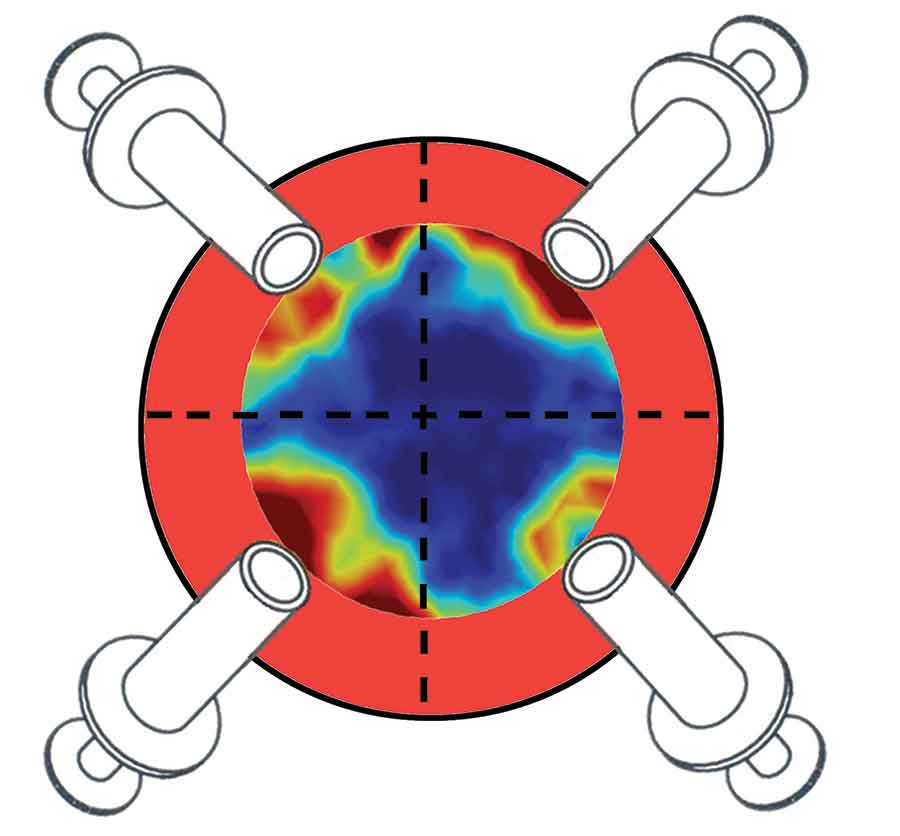

In FCC Units (Fluidised Catalyst Cracking Units), the atmospheric residue from the distillation is cracked to LPG, naptha and other components. This sometimes leads to “invisible” deposits inside the riser.

Read More

Topics:

optimising plant processing,

plant processing,

Process Diagnostics,

process diagnostics technologies,

tracerco diagnostics,

optimising plant production,

fcc unit,

fccu unit refinery,

fcc,

fcc diagnostics,

fccu process,

fccu studies,

cracking unit,

fcc riser,

fcc troubleshooting,

fcc units,

fcc unit process,

fluid catalytic cracking diagnostics,

fluid catalytic cracking services,

fluid catalytic cracking unit,

Process Diagnostics Technology,

Catalytic cracking,

fcc cracking,

fcc process

Tru-Scan™ and Tru-Grid™ scans are powerful tools that give you valuable insights into packed and trayed towers, tanks, pipes and more. Using this field-proven predictive maintenance technique on distillation columns allows plant personnel to monitor tray or packing hydraulics. A sophisticated monitoring programme can track the effects of fouling or other incapacitating conditions to extend run times and identify maintenance requirements in advance of scheduled turnarounds.

Read More

Topics:

Process Diagnostics,

Distillation Column Performance,

distillation tower scanning,

distillation column maintenance,

tower scan,

gamma ray inspection distillation,

gamma scan distillationcolumns,

gamma scanning distillation columns,

process diagnostics technologies,

distillation column service,

tower scanning,

tracerco diagnostics,

separation tower scanning,

tower gamma scan,

distillation tower scan,

distillation column scan,

distillation column scanning