Tracerco Insight Vol. 8 Ed. 2 newsletter is now available.

The Tracerco Insight newsletter featuring some of our latest case studies illustrating how Tracerco was able to provide our customers the necessary data that allowed the operations staff to make informed decisions for troubleshooting and optimising their process. Read more to see what's inside the latest issue.

This issue contains the following articles:

- Optimizing Desalter Performance Is Just One of Tracerco's Specialties We Proudly Provide.

- Crude Vacuum Tower Wash Bed Optimization.

- Application Note - ThruVision™

- Manage and Control Your Turnaround Costs to Avoid Possible Surprises.

- New Product Announcement: PED-ER and PED-ER+

Read more on how to download the latest issue.

Read More

Topics:

nucleonic instrumentation,

Tru-Scan,

process diagnostics technologies,

gamma scan,

monitor wash bed coking,

tracer technology,

Tracer Study,

catalyst bed wash,

desalter optimization,

wash bed optimization,

manage turnaround costs,

Depropanizer scan tray damage,

desalter,

Tracerco Profiler,

crude vacuum tower,

turnaround critical path project,

pre-turnaround scans

"Measure the Difficult to Measure"

2019 Innovative Process Diagnostics Symposium

May 21, 2019 in Deer Park, Texas, USA - 8:00 am - 3:30 pm

May 23, 2019 in Gonzales, Louisiana, USA - 8:00 am - 3:30 pm

Reserve your space today.

Tracerco is happy to announce that we have rescheduled our symposium "Measuring the Difficult to Measure" to be held in Deer Park, Texas and Gonzales, Louisiana. These new dates allow both our refining and petrochemical customers the ability to schedule their time to attend the symposium. Read more to learn about the topics of discussion.

Read More

Topics:

solids buildup,

exchangers,

gamma scanning distillation columns,

pipeline blockage,

flare gas meter,

Flow Study,

fccu studies,

flare flow measurement,

fugitive flare flow,

verify flow meters,

flare flowrate data,

flow rate calculations,

Process Diagnostics Technology,

tray fouling,

gamma scan,

fcc services,

level detection devices,

packing mal-distribution,

liquid distribution,

quantitative analysis pack beds,

PackView Analysis,

packed bed towers,

packed bed scan,

monitor wash bed coking,

tomography scan,

off spec product,

online leak detection,

chemical leak test,

feed/effluent heat exchangers,

exchanger bundle leak testing,

Tracer Study,

packed bed performance analytics,

Damage to vessel internals,

trayed tower,

mass transfer diagnostics

Are you planning a scheduled turnaround and want to know the advantages of scanning before and after your planned turnaround?

A Tru-Scan™ or Tru-Grid™ Scan will assist in defining and developing a turnaround critical path project scope at an early stage ensuring that your turnaround meets your goals. The most common use of gamma scans is to give process engineers and operations an online tool that results in understanding how a column is performing. This data can be used in advance of a turnaround to identify tray or packing damage and other process problems without having to shut down the column for internal inspections. These results will fully prepare turnaround planners with the knowledge they need for critical path decisions that must be made prior to a shutdown. At other times the results from a Tru-Scan™ or Tru-Grid™ Scan can either justify an unscheduled shutdown or identify options that will enable a plant to continue operating until the next scheduled shutdown.

Read more on how Tracerco scanning technologies can help to develop a plan for your turnaround planning.

Read More

Topics:

Gamma Scanning,

Liquid maldistribution,

packed column,

Packed Beds,

Tru-Grid Scan,

Suspected maldistribution in packed beds,

turnaround schedules,

turnarounds,

turnaround planning,

tray fouling,

gamma scan,

liquid distribution,

quantitative analysis pack beds,

PackView Analysis,

packed bed towers,

packed bed scan,

packed bed performance analytics,

density of liquid,

fouling,

critical path

Diagnose and take control of fouling issues.

In some processes a common problem that towers experience over a period of time is fouling of trays and packing with solid deposits. Fouling can cause conditions such as liquid maldistribution in packed columns or premature entrainment/flooding in trayed columns resulting in a loss of efficiency and an increase in operating pressure drop. Fouling may result from foreign material entering a column or from polymerization or decomposition occurring inside the column. The fouling may start under normal conditions or begin to build due to abnormal operating conditions.

Read more on how Tracerco scanning technologies can help to develop a plan to implement a routine maintenance programme for assets with fouling issues.

Read More

Topics:

Gamma Scanning,

Liquid maldistribution,

packed column,

Packed Beds,

Tru-Grid Scan,

Suspected maldistribution in packed beds,

tray fouling,

gamma scan,

liquid distribution,

quantitative analysis pack beds,

PackView Analysis,

packed bed towers,

packed bed scan,

packed bed performance analytics,

density of liquid,

fouling

Advanced analytics introduce a numerical and easily understood approach to tower gamma scanning

Refinery and chemical plant operations depend heavily on distillation and separation towers. Tower gamma scanning is well established in the process industries as a qualitative tool to help troubleshoot towers. Advances in data analysis have lead to a quantitative approach in expressing gamma scan data in numerical terms easily understood by process and operations engineers.

In a recent Tracerco article published by Petroleum Quarterly Technology (PTQ) magazine you will be able to read three example case studies of packed towers that will answer questions concerning the state of liquid distribution through the packed bed and illustrate how Tracerco's PackView™ analysis was developed to consistently analyse Tru-Grid™ Scan data to reach a conclusive result.

CLICK HERE To read the full article (Page 69) published in the Q2 2018 Petroleum Quarterly Technology (PTQ) issue.

Read More

Topics:

Gamma Scanning,

Liquid maldistribution,

packed column,

Packed Beds,

Tru-Grid Scan,

Suspected maldistribution in packed beds,

gamma scan,

liquid distribution,

quantitative analysis pack beds,

PackView Analysis,

packed bed towers,

packed bed scan,

packed bed performance analytics,

density of liquid

Are you planning to “wash” a catalyst bed in a reactor and need to monitor process conditions?

Using Tru-Scan™ technology to detect liquid levels in pressure vessels and catalyst levels in reactors is a fast and extremely reliable measurement performed online. One of the problems operations staff faced when planning a catalyst “wash” was not having an indication of any accumulated liquid level in the bottom of the vessel to monitor the procedure. Read more on how Tracerco was able to assist a customer with monitoring the liquid level throughout their planned wash campaign.

Read More

Topics:

Tru-Scan,

gamma scan,

liquid restriction,

SRU Unit,

coke,

Sulphur Recovery Unit,

catalyst bed wash

The first issue of 2018's Tracerco Insight newsletter is now available.

Tracerco would like to wish you a Happy New Year. We are very much looking forward to celebrating our 60th anniversary in 2018.

To start the new year we have published the first issue of the Tracerco Insight newsletter featuring a few of our latest case studies illustrating how Tracerco was able to provide our customers the necessary data that allowed the operations staff to make informed decisions for troubleshooting and optimising their process.

Read More

Topics:

nucleonic instrumentation,

Tru-Scan,

gamma scan,

coke drum cycle,

coke drum optimization,

delayed coke drum,

feed/effluent heat exchangers,

tracer technology,

H2S Absorber,

Life cycle management,

Tracer Study,

SRU Unit,

coke,

Sulphur Recovery Unit,

catalyst bed wash,

Ammonia converter

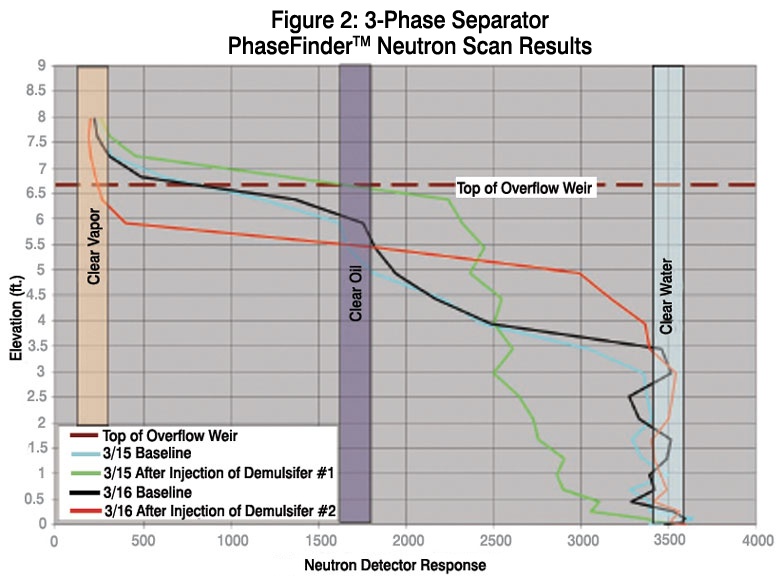

Scans aid plant personnel in determining which demulsifier is best suited for their application.

Tracerco’s scanning technology is an excellent means of measuring interface levels, whether between vapour and liquids, liquid and solids, or between two different types of liquids. Tru-Scan™ and PhaseFinder™ neutron scanning technologies can be used very effectively in trials of emulsion breaking chemicals to determine the best type and concentration to use in a particular vessel. This can lead to increased efficiency and significant cost savings as well as reduce the environmental impact of excess chemical use.

This blog will present two demulsifier trials that will show the difference in performance base on the presence or absence of an emulsion layer.

Read More

Topics:

neutron backscatter,

Tru-Scan,

gamma scan,

Separator,

PhaseFinder,

Demulsifier Chemical,

interface levels

Tru-Scan™ results assist with diagnosing problems even in a challenging process such as liquid-liquid extractors.

One category of special applications is liquid-liquid extractors. Besides the fact that liquid-liquid extractors are not “typical” distillation or fractionation unit operations, what makes them a special application for Tru-Scans™? The source and detector system that is used in scanning measures density changes of the process materials inside the tower. With a typical fractionation tower there is a large density difference between the vapour and liquid phases. Thus there is a large density range between clear vapour and clear liquid to detect process or operating conditions existing in a typical fractionation tower – entrainment, foaming, flooding, internal damage, etc. But liquid-liquid extractors are liquid full, with no large vapour-liquid density difference. Meaningful scan results from a liquid-liquid tower rely on the density difference between the two liquid phases being significant enough to distinguish as some extraction processes involve two liquids that have comparable densities.

So what will a Tracerco Tru-Scan™ of a liquid-liquid extractor tower show?

Since we do not have the large vapour-liquid density difference to work with, the information learned from a scan of a liquid-liquid extractor is less extensive than for a “typical” fractionation tower but not any less important. As the following examples show, scans of liquid-liquid extractors can detect problems when the two liquid phases are not properly mixing, preventing the tower from doing its proper extraction operation.

Read More

Topics:

gamma scan,

liquid liquid extractor,

extraction tower,

trayed extraction tower,

liquid restriction

On a regular basis customers see evidence suggesting the presence of a leak; such as a drop in process efficiency or the presence of a contaminant in product. This raises the question of where in the plant the leak is occurring or is the off-spec material do to some other problem.

In this latest blog, Tracerco, part of Johnson Matthey Plc, discusses how chemical tracers allowed the customer to replace a leaking exchanger bundle and restart the unit with minimal downtime.

Read More

Topics:

gamma scan,

off spec product,

online leak detection,

chemical leak test,

feed/effluent heat exchangers,

exchanger bundle leak testing