Are you planning to “wash” a catalyst bed in a reactor and need to monitor process conditions?

Using Tru-Scan™ technology to detect liquid levels in pressure vessels and catalyst levels in reactors is a fast and extremely reliable measurement performed online. One of the problems operations staff faced when planning a catalyst “wash” was not having an indication of any accumulated liquid level in the bottom of the vessel to monitor the procedure. Read more on how Tracerco was able to assist a customer with monitoring the liquid level throughout their planned wash campaign.

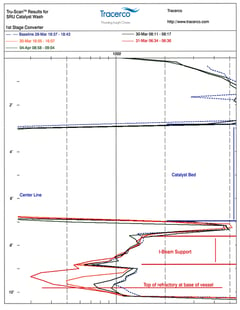

The following day six additional scans were completed but still no indication of accumulated liquid. On Day 3 the results of the scans showed the density in the bottom of the reactor had increased, signifying the presence of accumulated liquid (black solid scanline). The reactor level was monitored throughout the day at one hour intervals revealing that the liquid level rose slowly but steadily over the course of the day. The orange solid scanline was the final scan performed on Day 3.

Early on the morning of Day 4 the reactor was scanned showing the liquid level had risen to the bottom of the I-Beam support for the catalyst bed. This was the highest liquid level observed (red solid scanline). At this point the washing of the catalyst bed had been completed and further scans performed were used to monitor the liquid level receding. The reactor was scanned two more times after the completion of the wash on Day 5 with each scan indicating a continuing drop in the liquid level.

The final scan performed on Day 8 (green solid scanline) indicated that the reactor had returned to the baseline condition.

If you are planning to “wash” a catalyst bed of a reactor or any other unusual procedure and have the need to monitor process conditions consider using Tru-Scan™, stationary monitoring or PhaseFinder™ neutron scans to provide insight during the project. If you have any additional questions complete the enquiry form on our Tracerco website at https://www.tracerco.com/enquiries.

Click here to download a copy of our Tracerco Diagnostics™ Services for the Refining and Petrochemcial Industries brochure highlighting our Process Diagnostic™ applications.

Visit our website to subscribe to future issues of Tracerco Insight. https://www.tracerco.com/news-newslettersubscription.asp