You may recognize Tracerco as the world leader in providing a wide range of scanning applications, but we would like to provide you some insight as to how we are the industry leader in tracer studies, heat exchanger leak testing, flowrate measurements, gas meter proving, monitoring for pipe blockage and FCC studies.

If you are looking to isolate mystery flare flows, detect heat exchanger leaks, optimize your desalter or to detect blockages within your piping system, Tracerco has the technology that can provide you with all the information you need.

If you would like to schedule an onsite presentation to learn more about our Process Diagnostic technologies or receive case studies on how our tracer and specialty scan technologies are able to help minimize unit downtime and optimize processes, please click here to submit your request.

Read More

Topics:

leaking exchangers,

Liquid maldistribution,

optimising plant production,

Suspected maldistribution in packed beds,

Flow Study,

fcc diagnostics,

flare system tracers,

flare flow,

excessive flare flow,

fcc troubleshooting,

fcc unit process,

fluid catalytic cracking unit,

fugitive flare flow,

verify flow meters,

flare lines,

gas meter proving techniques,

fcc services,

coke drum,

coker optimization,

delayed coke drum,

liquid distribution,

tomography scan,

off spec product,

online leak detection,

chemical leak test,

feed/effluent heat exchangers,

exchanger bundle leak testing,

Tracer Study,

density of liquid

The first issue of 2018's Tracerco Insight newsletter is now available.

Tracerco would like to wish you a Happy New Year. We are very much looking forward to celebrating our 60th anniversary in 2018.

To start the new year we have published the first issue of the Tracerco Insight newsletter featuring a few of our latest case studies illustrating how Tracerco was able to provide our customers the necessary data that allowed the operations staff to make informed decisions for troubleshooting and optimising their process.

Read More

Topics:

nucleonic instrumentation,

Tru-Scan,

gamma scan,

coke drum cycle,

coke drum optimization,

delayed coke drum,

feed/effluent heat exchangers,

tracer technology,

H2S Absorber,

Life cycle management,

Tracer Study,

SRU Unit,

coke,

Sulphur Recovery Unit,

catalyst bed wash,

Ammonia converter

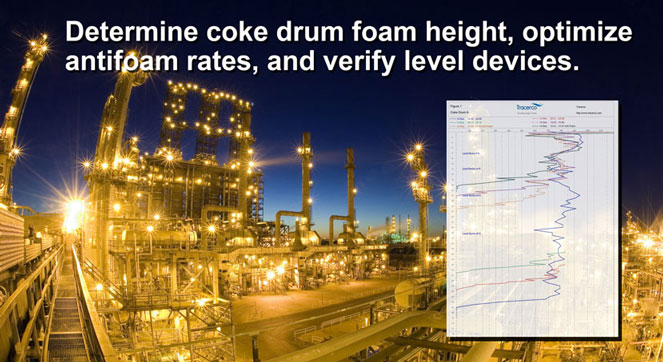

Tru-Scan™ is used by refineries to define foam profiles and verify level detection devices in their coke drums. A Tru-Scan™ can determine the difference in vapour density throughout a typical drum cycle.

In this latest blog, Tracerco, discusses how a Tru-Scan™ can be a powerful tool for gathering much needed information to optimise a coke drum cycle.

Read More

Topics:

Gamma Scanning,

Tru-Scan,

coke buildup,

coke deposits,

gamma scan,

level detection devices,

coke drum cycle,

coke drum optimization,

coke drum,

foam profile,

coker optimization,

coker units,

delayed coke drum