Tru-Scan™ is used by refineries to define foam profiles and verify level detection devices in their coke drums. A Tru-Scan™ can determine the difference in vapour density throughout a typical drum cycle.

In this latest blog, Tracerco, discusses how a Tru-Scan™ can be a powerful tool for gathering much needed information to optimise a coke drum cycle.

Knowing where the foam level is at any time during the batch cycle is vital to controlling coker operations. This is particularly true during "switch", the time when coker feed is diverted from one coke drum to another. A Tru-Scan™ will identify the location of the foam front during the switch.

Project Field Test

A customer requested a Coke Drum Optimization study be performed on their A and B coke drums to determine foam heights and verify the accuracy of their level devices. They also wanted to determine the effectiveness of their current antifoam system.

Project Analysis

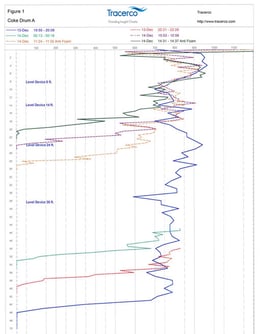

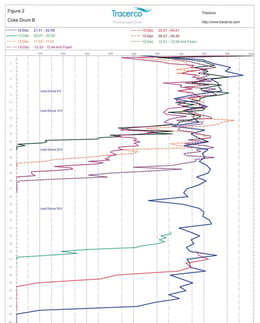

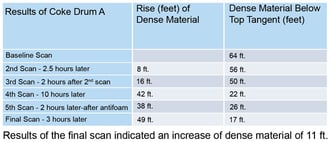

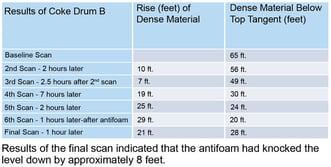

Coke drums A and B were scanned (Figures 1 and 2, shown right) at various times before, during and after the switch to verify the density differences during  the cycle. Tru-Scan™ results for coke drums A and B are shown in Tables A and B below.

the cycle. Tru-Scan™ results for coke drums A and B are shown in Tables A and B below.

Nuclear Level Device Calibration

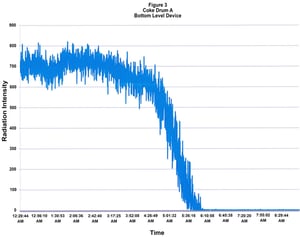

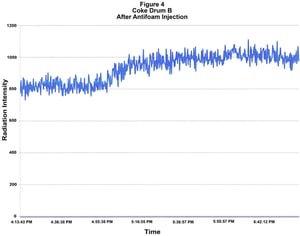

Stationary monitoring scans were performed on drums A and B at each elevation where a nuclear level device was installed. Scan results at each location provided the dates, times, radiation intensity count rates, the presence of foam and when antifoam was introduced. These time studies were used to determine density versus time to establish the sensitivity of the level indicating devices. Figure 3 shows the results of one of the stationary monitoring scans performed at the elevation of the bottom nuclear level device on Coke Drum A where the foam front was advancing as evidenced in the reduction in the count rate. Figure 4 shows the results from Coke Drum B where the foam receded after the antifoam injection.

With the results from the stationary scans the level devices were calibrated to allow the customer to determine the appropriate amount of antifoam.

Conclusion

Based upon the coke drum Tru-Scan™ results, it appeared as though foam was not being carried overhead at any time during the study. The Tru-Scan™ results indicated that the antifoam was successful in reducing the foam front.

The ultimate objective of a Coke Drum Optimization Study is to modify operating procedures in order to implement a more precise foam height control strategy. This includes periodic testing, to assure that the coker utilization strategy is appropriate for the feedstock, charge rate, and other conditions that are subject to change. Optimising antifoam rates alleviates unnecessary maintenance and turnarounds of downstream hydrotreater units in addition to enabling refiners to increase coker throughput with little or no capital cost. Tru-Scans™ performed before and after a switch identify the minimum outage safely obtainable.

Visit our website locations page to reach a Tracerco technical advisor in your area for additional information.

If you want to learn more about how Tracerco's technology enable's you to make the right decision, click here to request more information.