Oil, gas and water-based chemical tracers provide a true understanding of reservoir fluid flow pathways. It helps oil companies continuously monitor their reservoir and optimise drilling, completion and oil development strategies to maximise oil production.

In this blog we will discuss using a case study example, how our range of specialist chemical tracers can provide operators with critical insights without the need for well intervention or deferred production which can result in significant savings.

The Challenge

The first inflow tracer technology application in a UAE offshore field was performed with the expertise and

industry-leading technologies of Tracerco. In this study, an operator needed to collect fluid flow data in offshore oil producers in a new field development over a period of multiple years. Though production logging tools (PLTs) had been used in the past for a “snap shot” of production along the well laterals, these tools proved expensive for repetitive use and required the well to be shut-in each time a new dataset was to be collected. In its place, a project using Tracerco’s inflow tracer technology was used in order to achieve a similar quantitative understanding of the flow profile during transient production periods as well as an

on-going qualitative understanding of production during steady-state production, all without the need to stop production and at a lower price point than PLT operations. The typical well design was a 3300-ft horizontal lateral directionally drilled at an 87˚ inclination, allowing the well to intersect multiple discrete layers. Of these layers, five were expected to be productive oil layers, each with a high GOR (1425 scf/stb) and 36˚ API oil gravity. Each well was completed with liner and swellable packers with peripheral water injection support. The primary challenge for the operator was maintaining low development costs without

jeopardising either reservoir health or ultimate recovery.

The Solution

As part of the installed well completion, solid polymer tracer was attached along the lower completion liner.

These solid polymers were manufactured from non-dissolving material that encapsulate specialist chemical

tracers, allowing them to diffuse out of the polymer at a fixed rate when the polymer contacts a specific fluid

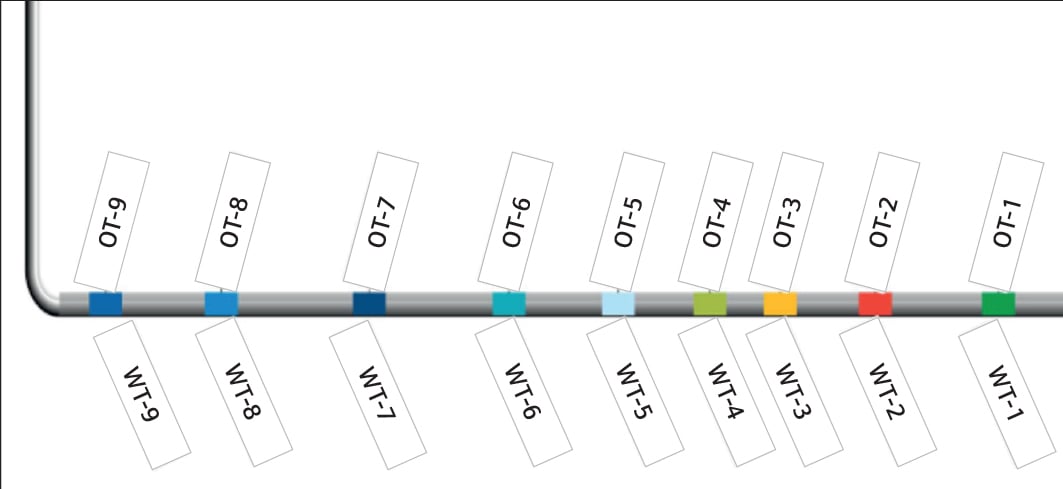

phase. The installed polymer was positioned into nine distinct zonal positions along the lateral with each zone containing a unique oil and water tracer signature assigned to that position.

Figure 1 - Unique oil and water tracer placement in each zone of the wellbore.

In the time prior to bringing the well online, each of these zones was potentially in contact with both oil and water (being a green field, the in-situ fluid was still above bubble point pressure so gas was initially ignored). During this shut-in period, tracer diffusion from its encapsulated solid polymer occurred and marked the

near-wellbore oil and water, creating a localised tracer “cloud” at each respective lateral position. With the start of production, the tracer cloud was driven into the production tubing alongside the reservoir fluid and produced to surface. Through analysis of tracer arrival times and knowing the volume of fluid within the production tubing that needed to be displaced prior to arrival, it was possible to provide a quantitative understanding of zonal inflow. In this way, it was possible to provide a definitive understanding of where

along the lateral oil and water was being produced and the relative rate of inflow at that position.

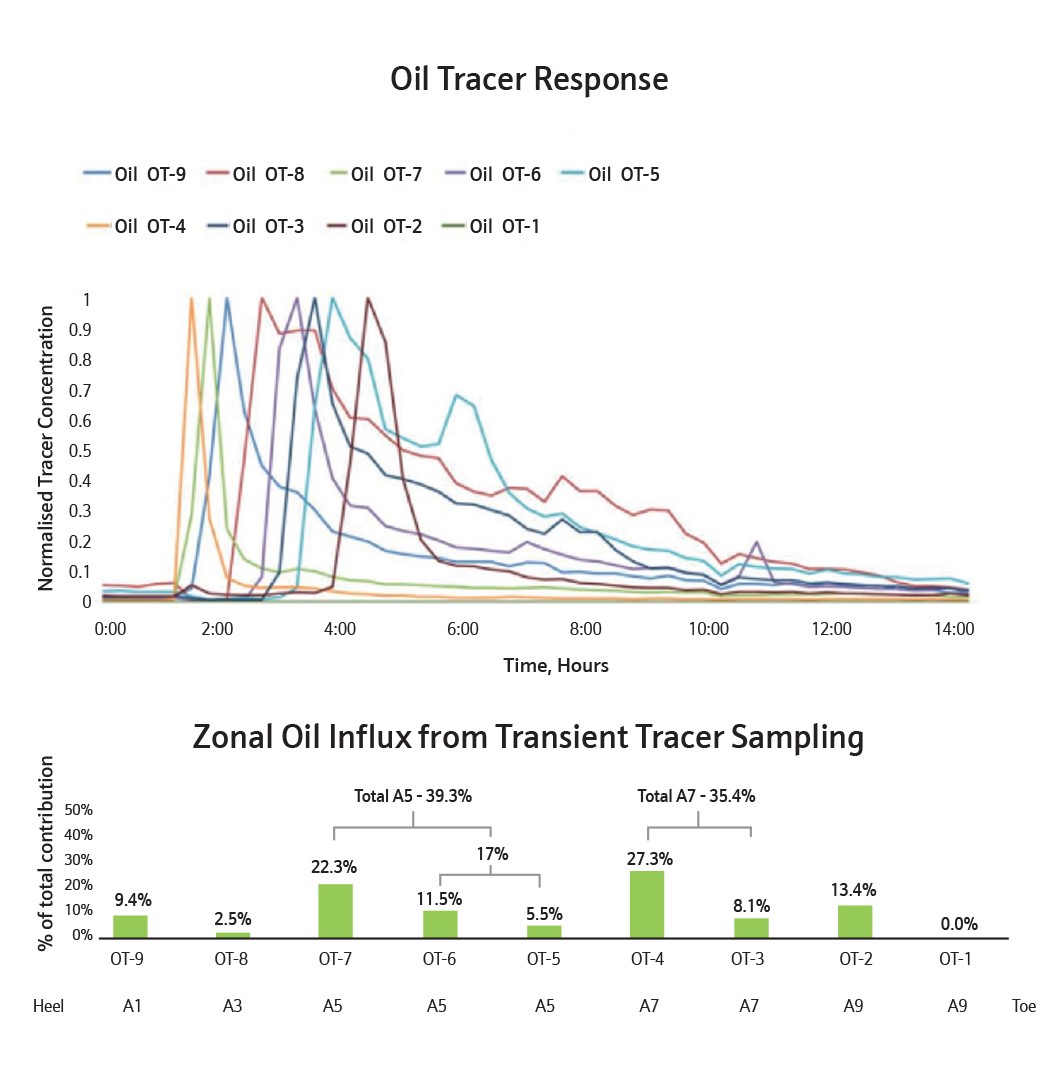

In the example shown in Figure 2, samples from production fluid allowed the varying tracer concentration to be measured against time, showing when the cloud from each tracer position arrived at surface. Using a mass balance along with the arrival time and rate of change in tracer concentration, this chart of tracer production was converted into an inflow profile along the lateral.

Figure 2 - Transient tracer data providing measurement of flow contribution along wellbore length.

Figure 2 - Transient tracer data providing measurement of flow contribution along wellbore length.

Comparison to Production Logging Tool (PLT) Data

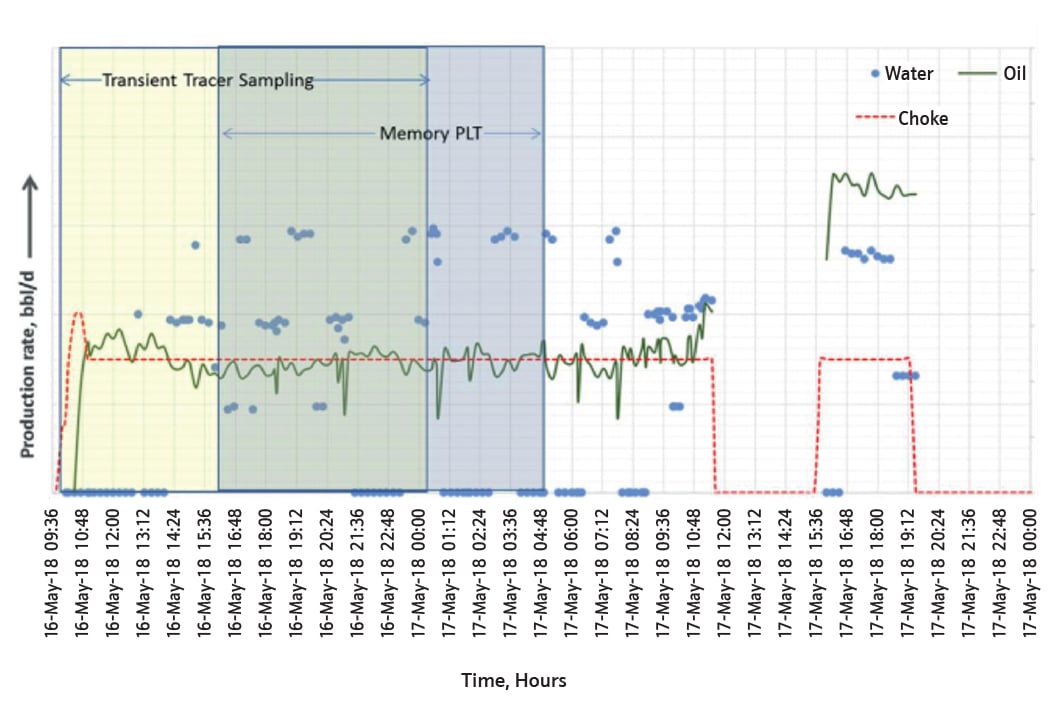

As this was the first use of inflow tracers for the operator, there was a need to compare the technique objectively to conventional data collection sources. As such, selected wells had a conventional PLT run in memory mode on the same day as transient tracer sampling in order to collect what should be comparable data from the simultaneous operations. This is shown in Figure 3. Both data collection systems provided similar results, with the majority of flow contribution achieved in the mid-toe region corresponding to layers A5, A7, and A9. The heel segments, corresponding to layers A1 and A3, were found to contribute very little to the overall well production. For the operator, the PLT validated the data collected via the inflow tracer study, both of which showed high agreement to the reservoir behaviour predicted from well logs and simulation modelling.

Figure 3 - Timing of tracer transient and PLT data collection.

The Conclusion

Both PLTs and transient inflow tracer studies provided consistent, clear information about how oil and water

production was distributed across the lateral. Yet through the use of Tracerco’s polymer tracer technology,

the operator gained data without the need for well intervention or deferred production as is typical with a

PLT. In addition, the use of polymer inflow tracers offered a 78% savings over a five-year PLT program, the equivalent of a $10 million USD cost reduction for a ten well offshore program with no compromise in data quality or content. For more details, please read SPE paper 193246-MS in which the operator goes in-depth into the tracer study and the results of their partnership with the experts at Tracerco.

Chemical tracer technology provides critical fluid flow information, accurately measuring water, gas and oil flow. It can help you to continuously monitor your reservoir and optimise drilling, completion and oil development strategies to maximise oil production. To find out more, watch our webinar: Chemical tracer technology or download the case study.