With the oil price remaining low, the entire oil and gas industry together with their supply chain are faced with the challenge of producing more for less. Constantly looking to cut costs without compromising on production or quality of product, technologies demonstrate their value not only in how they can help optimise production at any stage in the hydrocarbon production and processing chains, but also in how they can act as enablers to operators who need to save on the cost of producing oil and gas.

In this post we examine three steps to achieving savings of as much as 66% in drilling costs by using accurate flow data to optimise well spacing in unconventional fields. Tweet this.

This is based on our vast experience across numerous fields and the insights and figures come from real projects conducted over the last few years.

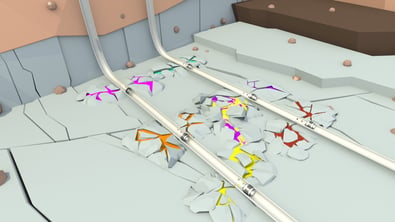

Well-spacing in fracking a field is a notoriously difficult balancing act: put wells too far apart and yield is compromised, put them too close and you waste drilling time and costs. How can you ensure that you are not needlessly drilling?

Step 1: Establish well connectivity

The linchpin of saving on drilling costs begins with accurately establishing well connectivity. The challenge faced by many operators in optimising their unconventional field is establishing connectivity between wells. Reservoir modeling can assist with this, but without real data on flow behaviour within the stages it is difficult to make an exact call regarding connectivity.

One way to be completely accurate on the connectivity between wells is to use smart tracers within the stages. They are very accurate - the oil tracer partitioning coefficient, for example, is 100,000 times more favourable to oil than water and they are unaffected by pumping systems. This can establish the optimum connectivity between wells.

Smart tracer technology can measure water oil and gas and we have hundreds of unique tracers meaning many stages can be measured in one frac completion. It is very easy to apply, being injected into the main flow of frac fluid at each stage. Tracer technology is well established and our customers have been using it for over 30 years in their conventional fields to measure fluid flow.

Sample collection can be taken by the operators with specialist kits that we provide, and sent to our specialist world-wide labs or, with the introduction of our new mobile labs, we can do on-site analysis for instant feedback.

Samples are typically collected twice a day for the first ten days, then once a day for the remainder of the first month, then weekly. The tracing process can last anywhere from a month to beyond a year depending on the flow of the well - the project is effectively complete when all of the tracer has been recovered.

After just ten days, we produce an early-time report, followed up by monthly reports, with the stage that produces all of its tracer first revealed as the most prolific producer in the well.

Step 2: Optimise your well spacing

The data from these reports is vital in establishing accurate well spacing. The advantages of optimised well spacing are most notable in terms of the cost saving but can also increase environmental compliance.

Tracer response from the samples will establish exact data on the connectivity or not of wells, enabling decisions to be made regarding the spacing of the next well. This knowledge will give operators the confidence that production is not compromised from reduced connectivity as this has already been established. This also empowers operators to decide when not to drill, saving millions on unnecessary drilling costs.

Ultimately you can confidently optimise development plans through the additional data gained from a smart tracer project.

Step 3: Save on drilling costs

You can now optimise field development plans by cutting unnecessary drilling programs, saving on all the associated costs with drilling a well. In fact, our tracer technology projects have seen operators reduce drilling costs by between 20% and 66% after identifying too much connectivity between wells.

Using smart tracers can save you up to 66% in drilling costs in unconventional fields by accurately establishing well connectivity in order to optimise well spacing. We hope you have found this post useful and if you want to learn more you can book a lunch and learn. You can also read our previous post, Five reasons to use chemical tracers in your frac applications. If you have enjoyed this post sign up for updates using the form on this page.

When do you think the oil price will return? Let us know in the comments below.