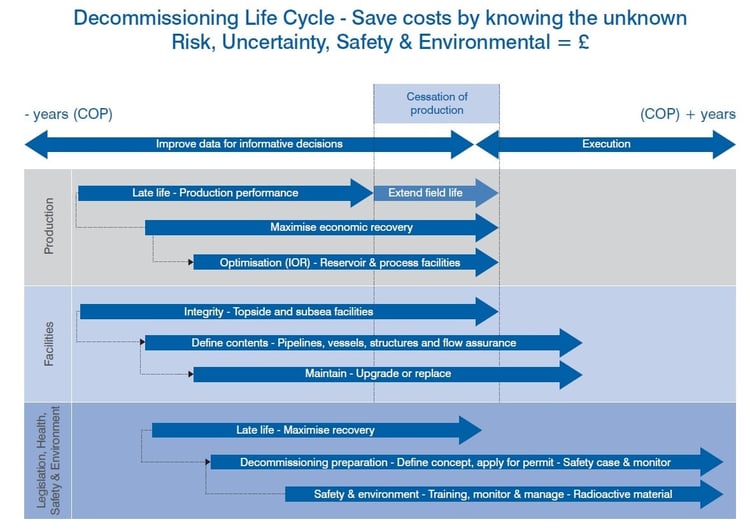

The challenging conditions faced in today’s oil and gas market has increased the focus on cost effective, sustainable operations. Operators are faced with the decision of extending or ending offshore production asset life and pre-decommissioning planning has emerged as a key challenge for the industry. Mitigating uncertainty, enabling decision making and justification as to whether to end or extend asset life, as well as detailed knowledge of asset conditions is crucial. In this blog, we will discuss how a range of Diagnostics services can be used to provide this detailed knowledge throughout late life operations.

Extending Asset Life

In assessing whether to extend asset life, inspection of asset structures to obtain detailed data on the condition of those assets is crucial to deciding if asset life and production is safe to extend. In cases of initial assessment, technologies that can confirm structural integrity with regard to pipeline corrosion and erosion, flexible riser liner and carcass inspection, midwater arch/buoyancy tank inspection, platform member inspection and grout monitoring is essential. These technologies, all of which are provided by Tracerco, are also vital during extended life campaigns, as regular inspection is required to confirm the viability of the asset.rvices/drilling-and-production/reservoir-interwell-connectivity/

With regard to ongoing processing, data provided through innovative detection, diagnostic and measurement technologies can ensure sustainable, cost effective production. Reservoir recovery is circa 30% to 40%, and with IOR/EOR technologies as an industry we have experienced a significant impact, where these percentages have been significantly increased. In IOR/EOR applications, chemical tracer technology can be used to manage fluid movement and maximise hydrocarbon output by establishing water entry points, providing a water cut profile along the wellbore and confirming the water source from the formation or injection water movement when combined with waterflood tracing.

In terms of field development planning, Tracerco’s technologies can also allow Operators to identify high flow permeable channel blocking and confirm the effectiveness of chemical treatment. In addition, operators can also measure waterflood effectiveness, residual oil saturation, water and oil inflow - which can often be used as an alternative to PLT’s where they are deemed too risky, costly, or well design does not permit - as well as effective water injection and mud invasion. Tracerco also offers added safety measures during logging while drilling (LWD) using a specially designed monitor for source detection.

Ending Asset Life

In the event assets are assessed and found to be no longer viable, decommissioning planning and execution must begin. The important factor here is to ensure that the route taken mitigates risk and is carried out safely, considering the best interests of the environment as well as complying with local regulations and legislation.

Tracerco’s technologies provide detailed knowledge of asset conditions, allowing operators to make informed decisions on their dismantle and disposal strategy. Tracerco’s diagnostic services can give information on the integrity of structures which can justify safe decommissioning. Knowledge of platform member integrity and flowline contents allows operators to assess the weight of structures (as well as ensure they are free from deposits/blockages) before any lifting, ensuing safe dismantling. Tracerco also offers expertise and equipment for NORM and LSA scale management, detection, and disposal - ensuring that decommissioning is as safe as possible. These services are also valuable in radioactive source recycling, further enhancing the safety and sustainability of operators’ decommissioning programmes.

To learn more about Tracerco's diagnostic services for decommissioning, please contact us.