Interactions between fractures in adjacent horizontal wells and development of methods for mitigating their costly negative effects has become the focus of much discussion within the industry. Operators are now acutely aware that one of the key challenges of infill development is avoiding interwell communication between Parent and newly drilled and fractured infill wells.

The impetus for this attention is centered around the negative impacts these interactions can have on the productivity and mechanical integrity of Parent and Child Wells alike. Without an effective means to mitigate these interactions, nearby Parent Wells can suffer from severe production degradation while Child Wells suffer from Estimated Ultimate Recovery (EUR) losses.

In this blog we will discuss - with a case example, how our range of specialist chemical tracers can allow operators to accurately quantify interwell communication, as well as evaluate the effectiveness of various mitigation techniques.

Monitoring well communication using chemical tracers

To minimise the impact of infill development on existing wells and achieve larger Stimulated Reservoir Volume (SRV) on infill wells, many operators are employing various mitigation strategies to protect their existing producers and better control the propagation of infill wells. Some of the most common mitigation techniques include:

- Shutting-in the Parent Well: By shutting in the Parent Well for a period of days to months, the reservoir may naturally re-pressurise the depleted zone or artificially re-pressurise the Parent Well: Injecting fluid “preloads”, either water or gas, can effectively restore the localised reservoir pressure prior to fracturing infill wells.

- Use of Far-Field Diverters: Similar to near-well diverters, far-field diverters serve to slow fracture growth further out into the fracture to prevent frac hits and interwell communication. However, these diverters carry a risk of potentially shutting off clusters that are receiving less rate during the stimulation process.

The problem, however, is that selection of an optimal mitigation strategy is not clear cut, and what works in one basin may not work in another. Therefore, it is imperative to understand Parent-Child interactions at a basin-level and determine which mitigation technique works best.

The Solution

Utilising tracers in previous pads, a customer noticed that infill wells landed in target intervals above an established Parent Well would consistently develop a strong, long-term downward communication trend to the lower Parent Well. This led to a revised development strategy that focused on placing Child Wells exclusively in targets below a respective Parent Well to reduce communication. However, a need still existed to mitigate the fracture interference that continued to occur after infill stimulation. Liquid chemical tracers were used to compare the effectiveness of Parent Well shut-in to a strategy of pre-loading the Parent Well prior to stimulating infill wells.

The focus of the study was centered around two pads drilled in a similar stacked configuration. In both pads,

two development wells were landed beneath an existing Parent Well in a lower target layer. For both pads, the Parent Well had been on production for roughly two years, so a well-developed depletion zone was expected to surround the Parent Well. Unique pairs of oil and water tracers were added to each of the Child Wells 28 stages during the stimulation to quantify the amount of inter-well communication between the wells.

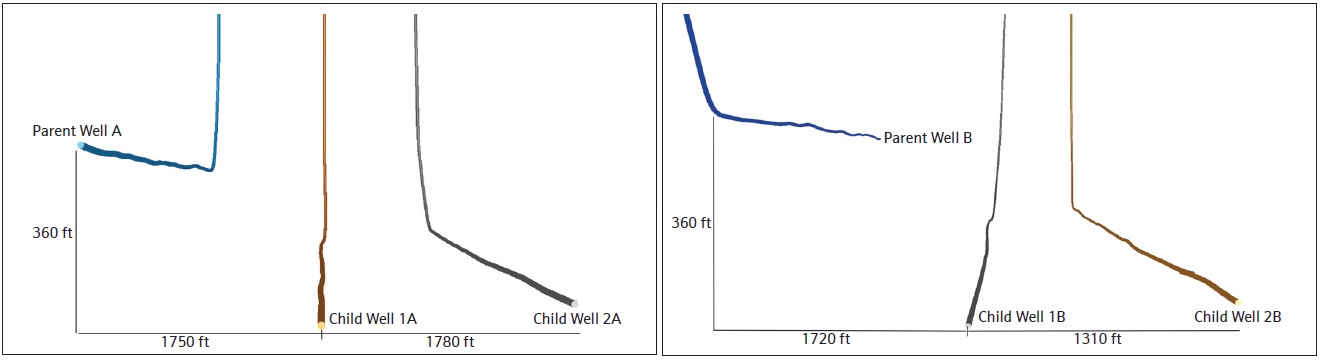

For Pad A, the first infill well, Child Well 1A, was landed 360 feet below the existing Parent and offset 1,750 feet laterally while the second infill well, Child Well 2A, was 360 feet below the existing Parent and offset an additional 1,780 ft laterally for a total horizontal distance of 3,530 from the Parent well. The Parent Well A was shut-in and allowed to naturally re-pressurise through movement of fluid within the reservoir. Pad B had a similar lateral arrangement, with the nearest Child Well, Child Well 1B, laterally spaced 1,720 feet away and 355 feet below the Parent (Parent Well B). The second Child Well, Child Well 2B, was stepped out an additional 1,310 feet laterally for a total distance of 3,030 feet in the horizontal direction.

In this second pad, the Parent Well was pre-loaded with 30,000 bbls of water prior to any stimulation of the infill wells. Beyond this preloading, one additional variable change existed in the experimental pad (Pad B): the Child Wells were drilled in the opposite direction of the Parent Well, alternating in a north-south direction.

Figure 1 - Pad A - pad with shut-in parent well. Figure 2 - Pad B - pad with pre-loaded parent well.

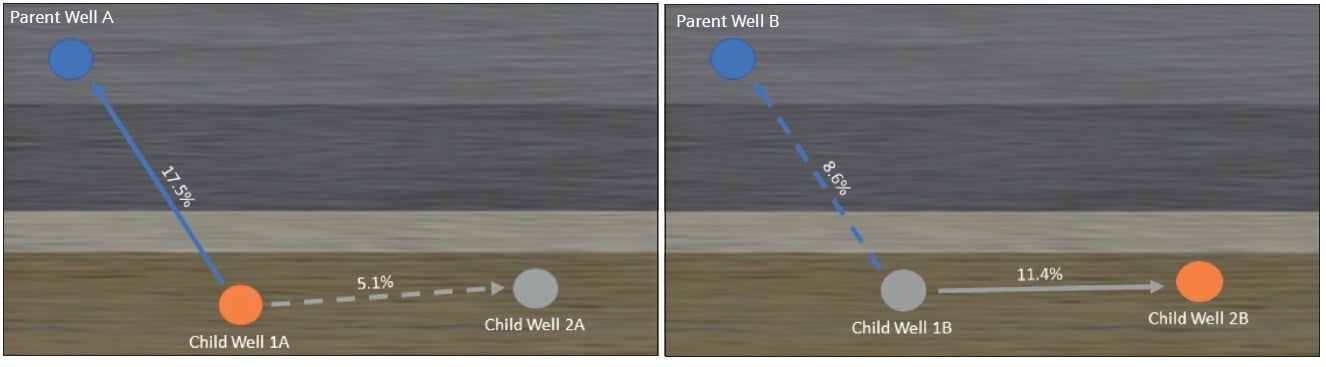

After 30-days of production, tracer data was used to quantify the amount of communication between wells. For the pad with the shut-in Parent Well, roughly 5.1% of the water tracer injected into Child Well 1A was produced at the second infill well, 2A. This communication was not bi-directional and was evaluated as being fairly minimal, suggesting that the well spacing was sufficient to control communication. However, a significant amount of water tracer injected into 1A travelled to the depleted Parent Well A, above. Over 17% of the water tracer applied at the Child Well 1A was ultimately recovered at the Parent Wellhead, demonstrating that the well spacing was insufficient to overcome the asymmetric fracture growth related to depletion effects.

Figure 3 - Pad A communication summary. Figure 4 - Pad B communication summary.

In the pad with a pre-loaded Parent Well, tracer movement from the nearest infill well (Infill Well 1B) to the Parent Well was reduced 51% over the same 30-day period. However, an increased amount of tracer injected into the 1B was communicated to the second infill well, 2B. This may be ascribed to either the closer spacing of infill wells (26.4% closer than in pad one) or to increased fracture interference as a more symmetrical fracture network developed around 2B during well stimulation. Interestingly, as this experiment was repeated it was observed that in some formations the pump-in only protects the heel of the parent and not the entirety

of the lateral.

The Conclusion

Using liquid chemical tracers, an operator was able to rapidly quantify the effect of different fracture mitigation strategies. With minimal cost, and without the need for a large data set or multiple trial-and-error efforts, the drilling and completion strategy was able to be rapidly adapted with immediate improvements in EUR and net profitability.

Chemical tracers provided a demonstrable value, as a method to rapidly quantify the impact of well spacing, establish acceptable bench-to-bench communication with varying completion designs, and influence of Parent Wells during infill stimulation. To find out more, watch our webinar: Chemical tracer technology.