The verification of flare gas flow rates is an ongoing issue for many hydrocarbon producers globally, with strict environmental legislation continuing to impact oil or chemical processes. In this blog post we will review how the use of a Tracerco Diagnostics™ Flow Study can allow you to verify and calibrate flare flow meters, and locate the source of any fugitive flare flow, ensuring effective environmental reporting, as well as process optimisation and reduced downtime.

1. A Tracerco Diagnostics™ Flow Study. What does it do?

Tracerco Diagnostics™ Flow studies measure flowrates through flare lines or piping systems, monitor process changes over start-up/shutdown cycles and determine leakages past relief valves or block valves. Our flow study technology offers a non-instrusive, rapid, accurate, and cost effective method of determining flows of gas, water, and organic based materials.

2. How is a Tracerco Diagnostics™ Flow Study performed?

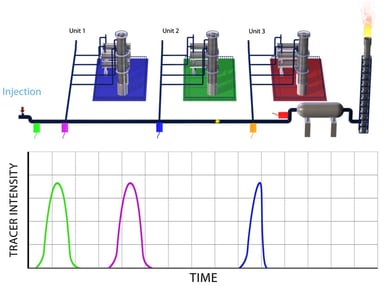

The most standard technique (Pulse Velocity) is to mount two or more radiation detectors on the outside of the pipe. A sharp pulse of tracer that is compatible with the gas, liquid, or solid in the pipe is injected into the process stream. The tracer mixes radially in the pipe and flows at the same velocity as the fluid. As the pulse of tracer passes each detector, the response is recorded. The time between the centroids of the response curves is the mean transit time of the tracer between the detectors and from this and detector separation, the flow velocity is calculated.

3. What information does a Tracerco Diagnostics™ Flow Study provide?

After a Tracerco Diagnostics™ Flow Study has been completed, the lead engineer will leave a preliminary report with the customer before leaving the plant site. A formal report will then be provided. A Tracerco Diagnostics™ Flow study is used to:

- Help our customers determine flow velocities.

- Isolate where flare flow is coming from within a flare line system.

- Verify and calibrate meters.

- Provide an independent verification that data reported for environmental purposes is correct.

- Information on where excess gas is entering a flare system - on a unit or equipment level.

- Determine the volume and thus the value of the material being lost to the flare.

- Monitor process changes over start-up/shutdown cycle.

- Determine leakage past relief valves or block valves.

- Perform mass/flow relationships through flare lines or piping systems.

- Verify and calibrate meters.

You can learn more about how a Tracerco Diagnostics™ Flow Study can enable you to make the right decision by downloading the full list of the questions and answers, or by watching our piping and flare systems animation.