The loss of catalyst through reactor or regenerator cyclones is a fairly common problem. Identifying the reason for the loss is often difficult.

In this latest blog, Tracerco, part of Johnson Matthey Plc, discusses how a Tru-Scan™ can be a powerful tool for gathering much needed information regarding the loss of catalyst.

When a specific isotope source is positioned on the outside of an FCC reactor or FCC regenerator at the top tangent line and a sensitive

detector is positioned on the other side and also at the top tangent line, the varying amount of radiation that the detector records is directly dependent on the density of the material inside the vessel. If the area inside the vessel is vapour, then most of the radiation passes through. If the area contains dense material, like catalyst, most of the radiation is absorbed, never reaching the detector. Lowering the source and detector synchronously down the side of the vessel can generate a density profile of the internals and catalyst.

Project Field Test

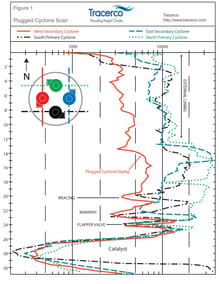

For one refinery, the primary cyclones were scanned.

Project Analysis

Results indicated one of the secondary cyclones and its dipleg were shown to be denser

than the other three. This was due to the fact that a blockage had developed in the dipleg and catalyst had filled the cyclone and dipleg . This problem meant that the catalyst entering the plugged secondary cyclone was not removed from the vapour but exited the reactor.

. This problem meant that the catalyst entering the plugged secondary cyclone was not removed from the vapour but exited the reactor.

Occasionally, a dipleg or cyclone is found to be blocked. Scan results provide confirmation of the problem cyclone so that critical operating decisions can be made.

Introduction to Johnson Matthey’s FCC Additives

Johnson Matthey offers a range of specialised FCC additives through the INTERCATTM brand. INTERCAT FCC additives are used in refinery FCCUs globally to tailor the selectivity of the unit, boost LPG yield at the expense of LCO and HCO, decrease bottom yields, and reduce regenerator SOx, NOx and CO emissions. INTERCAT addition systems allow refiners to add catalyst and additives to the FCC on a near continuous basis thus reducing additive and catalyst usage, improving FCC profitability through yield improvements, and reducing maintenance costs. The INTERCAT addition system IMS controller, monitors and logs daily catalyst and additive additions, simplifying negotiation of final FCC emission limits through data compilation and verification of testing results. For more information, visit the Johnson Matthey website.

If you want to learn more about how Tracerco's technology enable you to make the right decision, click here to request more information.