This post is the first of the "Diagnosing liquid maldistribution inside packed beds" series.

A challenge to process engineers is diagnosing liquid maldistribution problems inside packed beds that can cause severe mass transfer efficiency loss. In industrial distillation columns, common examples of the cause of liquid maldistribution are design, manufacture or installation defects of distributors as well as damage, plugging and process disturbance of packed beds.

In this latest blog, we will explain using a case study approach how Tracerco's scanning technologies can be used to diagnose suspected maldistribution in packed beds.

The first step to determine liquid maldistribution in a packed column is to perform a Tracerco Tru-Grid™ Scan to provide an initial look at the liquid distribution in the packing. A Tru-Grid™ scan consists of four equal-distant chords, one through each quadrant of the tower. Under ideal conditions and uniform liquid loadings, each scan plot will overlay closely with all others.

Case study

Case study

A petrochemical plant had just performed a major revamp of one of their most critical distillation towers. This tower was over 45m tall, more than 6m in diameter, and contained several large beds of structured packing. The scope of the revamp included removing all of the old distributors and packed beds and replacing them with a more efficient design.

Upon start-up, the tower was unusually unstable. The customer could not increase the feed to design rates while maintaining desired product quality. Both the overhead and bottoms products were off specification, even when the tower was running at reduced rates.

The first diagnostic step taken by plant personnel was sample analysis. Samples were collected at each packed bed, and the analysis of these samples indicated that all of the beds were performing poorly. What could not be determined by the samples was the reason that the beds were performing poorly. One possibility was liquid maldistribution through all beds. If the liquid distribution was good, then the packing was falling well short of its designed efficiency. Another possibility was that some type of mechanical damage might have occurred during start-up.

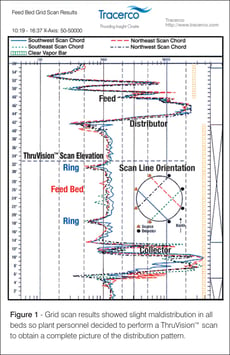

Tracerco was called to help diagnose the cause of the problem. The first step was to perform a Tru-Grid™ Scan of this tower. The results of the grid scan showed that all distributors, collectors, and packed beds were in place with no evidence of mechanical damage. (Figure 1) The Tru-Grid™ scan also showed slight liquid maldistribution in all of the beds, but it did not appear severe enough to cause the very poor efficiency of the tower. Liquid maldistribution had been strongly suspected and since the Tru-Grid™ Scan indicated that maldistribution could be an issue, plant personnel wanted to get as complete a picture of the distribution pattern, as possible.

A Tru-Grid™ Scan is one of the most cost effective methods of identifying liquid maldistribution and other problems affecting packed column performance. In order for Tracerco to provide our customer with a more in depth picture of the distribution pattern ThruVision™ scans were performed.

Next Edition: Liquid distribution within packed beds

In the next edition of our blog we will discuss how following a Tru-GridTM Scan our ThruVisionTM technology was able to obtain a more detailed liquid distribution profile of the packed bed, providing plant personnel with the data they needed to identify the best course of action to correct the problem.

If you want to learn more about how Tracerco’s technologies enable you to make the right decision, request more information.

Read the full series:

Part 1 – How to diagnose liquid maldistribution in packed beds: A case study - Part 1

Part 2 - How to diagnose liquid maldistribution in packed beds: A case study - Part 2