Gas plants play a critical role in cleaning raw natural gas after being extracted from subterranean deposits.

This process isolates hydrocarbons, non-methane fluids, hydrates and impurities to produce dry pipeline quality gas, which is then transported to the end user. These plants are generally low maintenance compared to oil refineries and most chemical processing complexes. However, they have limited options in the event of disruptions, degrading conditions or incoming raw gas flows. If these conditions do arise, scanning technology has proven to be an effective screening tool for providing detailed information about the hydraulic performance of trayed towers.

In this blog, we will discuss using a case study example how our online diagnostic Tru-Scan™ technology can identify abnormal process conditions and optimise unit/vessel efficiencies resulting in an increased unit capacity and significant savings.

The Field Test

A customer contacted Tracerco after they recently replaced their trays with a more efficient design, however, the newly installed trays were carrying liquid overhead at only 80% of production rates. The newer design was installed so they could obtain an additional 15% over their previous 100% production rates. The customer had previously shutdown and entered the vessel after start-up assuming the carryover would have been caused by solids or debris left behind during tray installation or start-up. After entry, they found no material or limitation that would have caused the liquid carryover. They closed the vessel and started back up, but again found themselves carrying liquid overhead at only 80% of the design load. This cost the

plant three days of downtime and production losses, not including several days of running at 80% of plant capacity prior to the shutdown and entry.

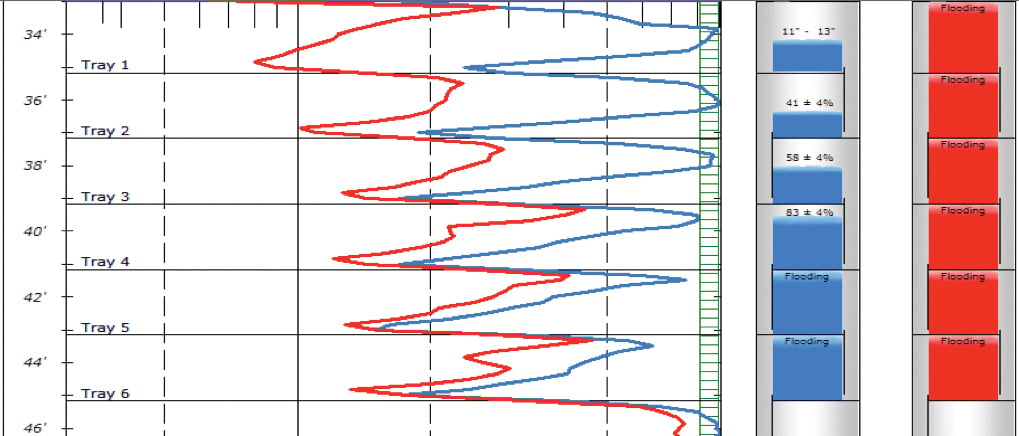

Figure 1 - Tru-Scan™ results conducted at different capacities indicated the location of flooding.

The Analysis

An initial Tru-Scan™ was conducted near 60-70% capacity where the customer was not experiencing issues

or increased pressure drop (Figure 1). This scan (blue scanline) showed the bottom 2 trays were in a flooding

state. A second scan (red scanline) was then completed at 80% capacity, which showed all the trays to be in a flooded state with liquid, well within the top head of the vessel. These scan results concluded that the initial liquid flood point originated at the bottom tray.

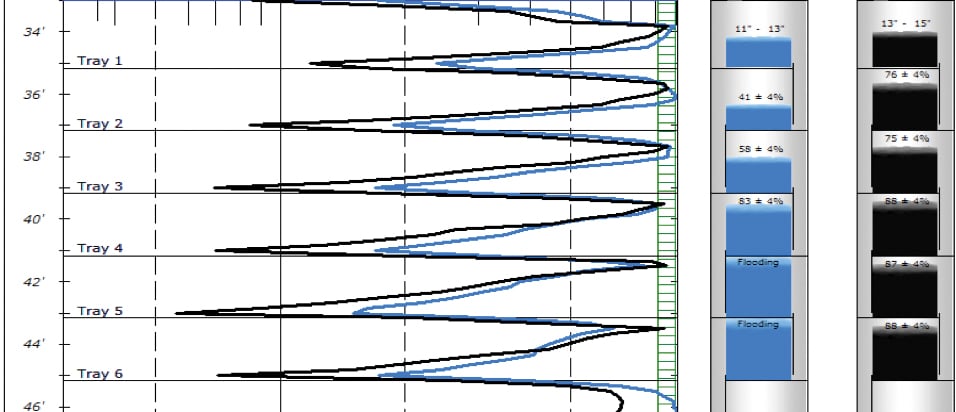

Figure 2 - A baseline scan showing tray operating capacity.

The customer re-evaluated their newly installed tray designs and found they had adjustable outlet weirs on

the trays. They decided to re-enter the vessel a few days later and found that the weirs were positioned to their maximum height. After adjusting the weirs to correct design specifications they were able to safely operate the tower with 115% of unit capacity without increased pressure drop or liquid carryover. A baseline scan (Figure 2) was requested and conducted at their current operating capacity. The baseline scan (black scanline) showed all trays to be operating between 75-88% tray spacing with no indications of liquid build-up or flooding.

The Conclusion

A Tru-Scan™ captures relative density signatures across a vessel’s internals. Tru-Scan™ results have proven to be an effective screening tool for providing detailed information about the hydraulic performance of trayed towers. Data results from the scan identified the initial liquid flood point, helping the customer to safely operate at 115% of unit capacity.

Our innovative work gives customers the insights they need to help solve their problems. To learn how scanning and tracer diagnostic services can help you quickly identify, resolve and improve operational issues, optimise and run your processes more efficiently and potentially save you millions of dollars every year watch our webinar; troubleshooting and optimising trayed and packed bed towers or download the case study.