With government regulations constantly evolving and varying based on localities, being able to isolate sources of fugitive emissions and repair or replace faulty equipment allows customers to remain compliant and avoid costly fines. To aid in this endeavour, Tracerco injects a variety of liquid and gaseous tracers to detect the presence of leaks within equipment whilst remaining fully operational.

In this blog, we will discuss using a case study example how our Tracerco Diagnostics™ Leak study identifies leaks resulting in massive savings from environmental fines, without any interruption to production.

A Tracerco Diagnostics™ Leak study is a fast and extremely reliable way to test for fugitive emissions leaking across compromised equipment. With government regulations constantly evolving and varying based on localities, being able to isolate sources of fugitive emissions and repair or replace faulty equipment allows customers to remain compliant and avoid costly fines. To aid in this endeavour, Tracerco injects a variety of liquid and gaseous tracers to detect the presence of leaks within equipment whilst remaining fully operational.

The Field Test

Tracerco was contacted to perform leak tests on pressure safety valve (PSV) tie-ins to the flare header throughout multiple units within a refinery. Operations had been experiencing high H2S concentrations reaching the flare and the issue was cause for concern regarding regulatory requirements. The customer had identified several PSVs they suspected as possible sources of fugitive emissions via the PSV bypass. A gaseous tracer material compatible with the system was chosen and introduced upstream of the selected PSVs. Detectors mounted externally to the flare piping were used to monitor any tracer flow bypassing the valve and entering the downstream piping. Additional detectors were also placed on the main flare header to confirm the presence of tracer in the main line and to measure the flow rate.

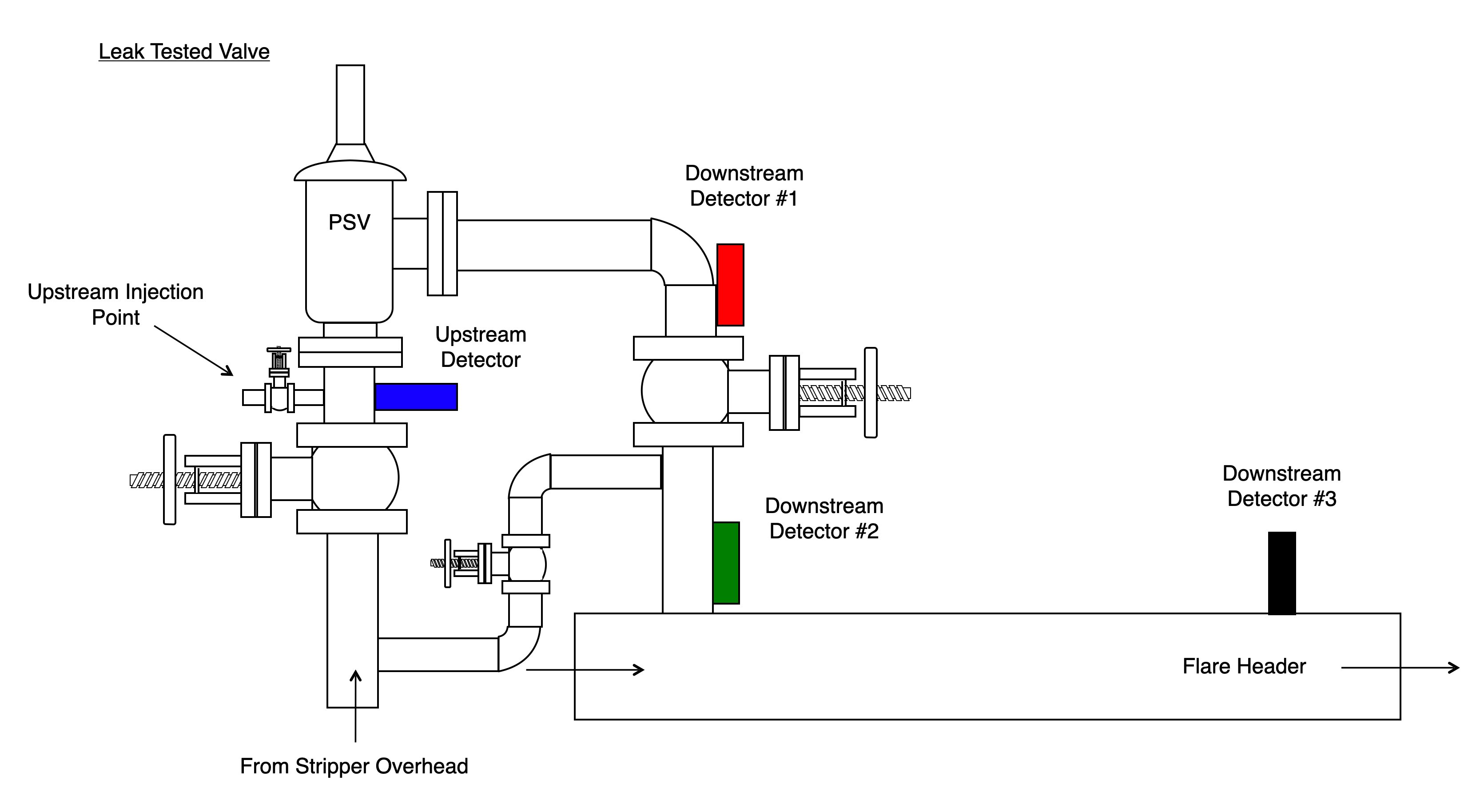

Figure 1 - Detector locations, flare valve leak testing.

The Analysis

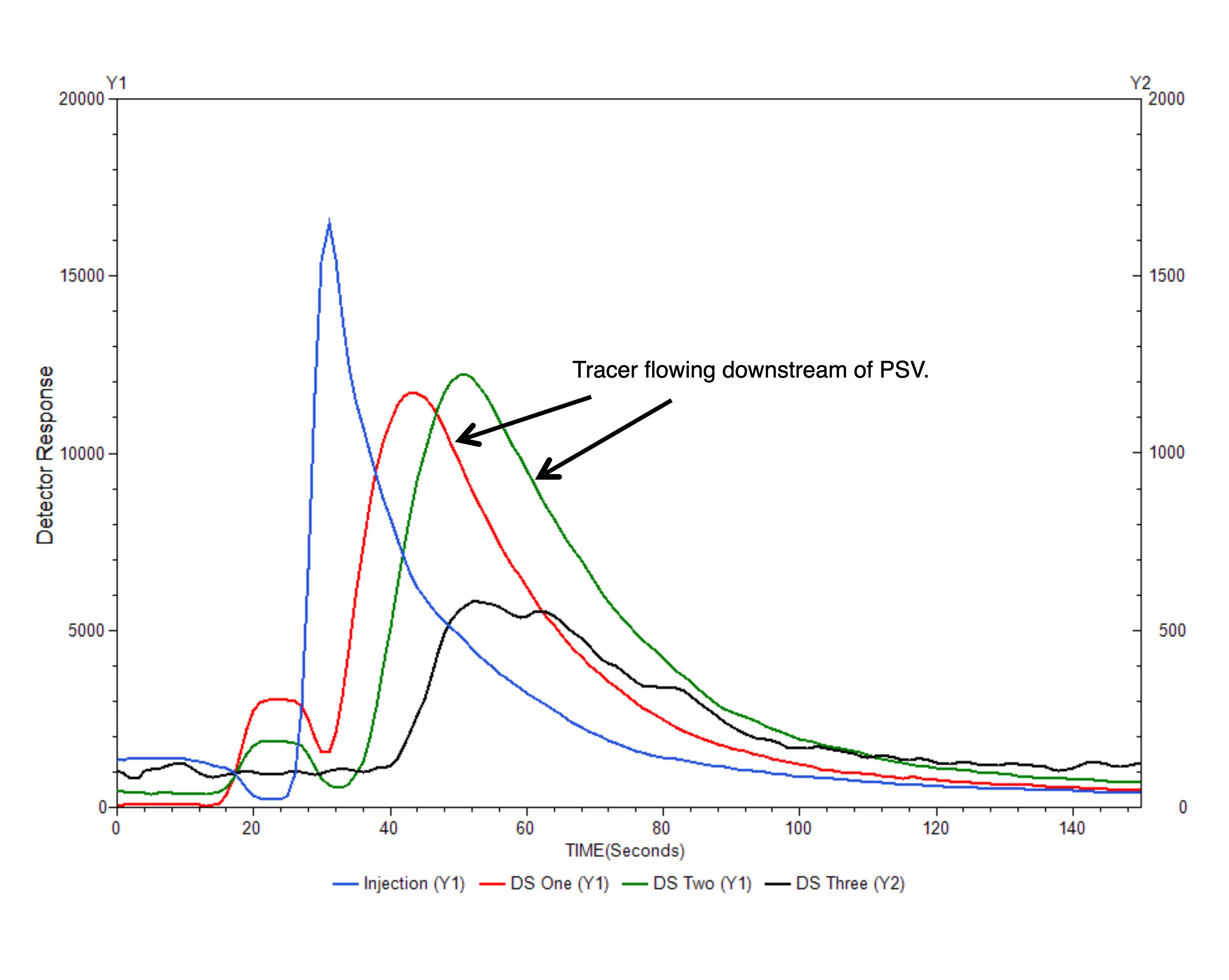

Of the PSVs that were tested throughout the refinery, a major leak was identified and confirmed across one PSV. The valve was leak tested by injecting tracer through an upstream bleeder and monitoring detectors downstream for a leak response. Figure 1 shows the approximate detector locations used to obtain the data. Figures 2 and 3 are plots showing the leak test results. The blue line, detector 1, shows the detector response at the injection point of the test. The data showed the tracer effectively entering at the upstream side of the valve. The upstream detector response immediately began decreasing after the injection. Soon afterward, downstream detectors (red, green, and black lines) returned a response as tracer passed downstream of the valve. These responses indicated a leak through this PSV.

Figure 2 - Results from the first injection, identifying the leaking PSV.

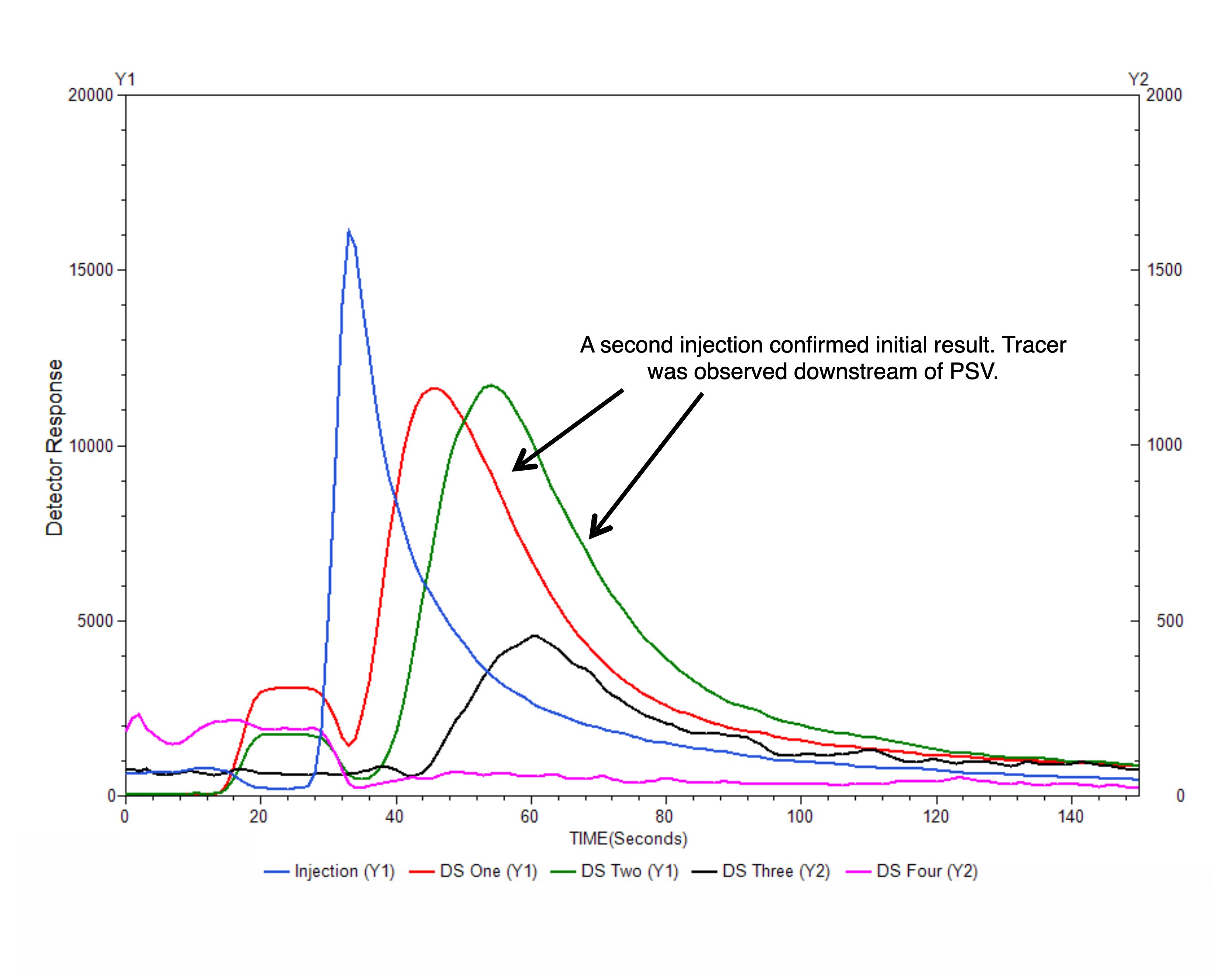

A second injection was conducted to confirm the leak. Similar responses were observed, shown in Figure 3, and process vapour appeared to be leaking past the PSV to the flare. The downstream detectors were placed at a known distance apart and when used in conjunction with the time of flight between the externally mounted detectors, a tracer velocity was calculated. The tracer velocity was then used with the known pipe dimensions to calculate a volumetric flowrate, allowing the customer to quantify the fugitive emissions from the leaking PSV.

Figure 3 - Results from the second study confirmed the leaking PSV.

The Conclusion

Shortly after the leak study, the customer was able to isolate and replace the valve. After installation, the H2S

leaving through the flare was greatly reduced which in turn reduced the fines that the customer was incurring from rogue emissions to the flare. This single valve, of the several that were tested, was the greatest contributor and the refinery was able to continue operation confidently without incurring significant fines and penalties. A single day of onsite work enabled our customer to isolate where the flare flow was coming from. Tracerco confirmed a substantial leak which resulted in massive savings from avoiding fines. The customer was also able to limit their environmental impact without interfering with production. The Tracerco Diagnostics™ Leak study was a fast and effective way to identify the source of the fugitive emissions that had been a long-standing issue at the plant.

A Tracerco Diagnostics™ Leak study is a fast and extremely reliable way to test for fugitive emissions leaking across compromised equipment.

Our innovative work gives customers the insights they need to help solve their problems. To learn how scanning and tracer diagnostic services can help you quickly identify, resolve and improve operational issues, optimise and run your processes more efficiently and potentially save you millions of dollars every year watch our webinar; optimising processes with data driven diagnostics solutions or download the case study.