You may recognize Tracerco as the world leader in providing a wide range of scanning applications, but we would like to provide you some insight as to how we are the industry leader in tracer studies, heat exchanger leak testing, flowrate measurements, gas meter proving, monitoring for pipe blockage and FCC studies.

If you are looking to isolate mystery flare flows, detect heat exchanger leaks, optimize your desalter or to detect blockages within your piping system, Tracerco has the technology that can provide you with all the information you need.

If you would like to schedule an onsite presentation to learn more about our Process Diagnostic technologies or receive case studies on how our tracer and specialty scan technologies are able to help minimize unit downtime and optimize processes, please click here to submit your request.

Read More

Topics:

leaking exchangers,

Liquid maldistribution,

optimising plant production,

Suspected maldistribution in packed beds,

Flow Study,

fcc diagnostics,

flare system tracers,

flare flow,

excessive flare flow,

fcc troubleshooting,

fcc unit process,

fluid catalytic cracking unit,

fugitive flare flow,

verify flow meters,

flare lines,

gas meter proving techniques,

fcc services,

coke drum,

coker optimization,

delayed coke drum,

liquid distribution,

tomography scan,

off spec product,

online leak detection,

chemical leak test,

feed/effluent heat exchangers,

exchanger bundle leak testing,

Tracer Study,

density of liquid

Are you planning a scheduled turnaround and want to know the advantages of scanning before and after your planned turnaround?

A Tru-Scan™ or Tru-Grid™ Scan will assist in defining and developing a turnaround critical path project scope at an early stage ensuring that your turnaround meets your goals. The most common use of gamma scans is to give process engineers and operations an online tool that results in understanding how a column is performing. This data can be used in advance of a turnaround to identify tray or packing damage and other process problems without having to shut down the column for internal inspections. These results will fully prepare turnaround planners with the knowledge they need for critical path decisions that must be made prior to a shutdown. At other times the results from a Tru-Scan™ or Tru-Grid™ Scan can either justify an unscheduled shutdown or identify options that will enable a plant to continue operating until the next scheduled shutdown.

Read more on how Tracerco scanning technologies can help to develop a plan for your turnaround planning.

Read More

Topics:

Gamma Scanning,

Liquid maldistribution,

packed column,

Packed Beds,

Tru-Grid Scan,

Suspected maldistribution in packed beds,

turnaround schedules,

turnarounds,

turnaround planning,

tray fouling,

gamma scan,

liquid distribution,

quantitative analysis pack beds,

PackView Analysis,

packed bed towers,

packed bed scan,

packed bed performance analytics,

density of liquid,

fouling,

critical path

Diagnose and take control of fouling issues.

In some processes a common problem that towers experience over a period of time is fouling of trays and packing with solid deposits. Fouling can cause conditions such as liquid maldistribution in packed columns or premature entrainment/flooding in trayed columns resulting in a loss of efficiency and an increase in operating pressure drop. Fouling may result from foreign material entering a column or from polymerization or decomposition occurring inside the column. The fouling may start under normal conditions or begin to build due to abnormal operating conditions.

Read more on how Tracerco scanning technologies can help to develop a plan to implement a routine maintenance programme for assets with fouling issues.

Read More

Topics:

Gamma Scanning,

Liquid maldistribution,

packed column,

Packed Beds,

Tru-Grid Scan,

Suspected maldistribution in packed beds,

tray fouling,

gamma scan,

liquid distribution,

quantitative analysis pack beds,

PackView Analysis,

packed bed towers,

packed bed scan,

packed bed performance analytics,

density of liquid,

fouling

Advanced analytics introduce a numerical and easily understood approach to tower gamma scanning

Refinery and chemical plant operations depend heavily on distillation and separation towers. Tower gamma scanning is well established in the process industries as a qualitative tool to help troubleshoot towers. Advances in data analysis have lead to a quantitative approach in expressing gamma scan data in numerical terms easily understood by process and operations engineers.

In a recent Tracerco article published by Petroleum Quarterly Technology (PTQ) magazine you will be able to read three example case studies of packed towers that will answer questions concerning the state of liquid distribution through the packed bed and illustrate how Tracerco's PackView™ analysis was developed to consistently analyse Tru-Grid™ Scan data to reach a conclusive result.

CLICK HERE To read the full article (Page 69) published in the Q2 2018 Petroleum Quarterly Technology (PTQ) issue.

Read More

Topics:

Gamma Scanning,

Liquid maldistribution,

packed column,

Packed Beds,

Tru-Grid Scan,

Suspected maldistribution in packed beds,

gamma scan,

liquid distribution,

quantitative analysis pack beds,

PackView Analysis,

packed bed towers,

packed bed scan,

packed bed performance analytics,

density of liquid

This post is the second part of the "Diagnosing liquid maldistribution inside packed beds" series.

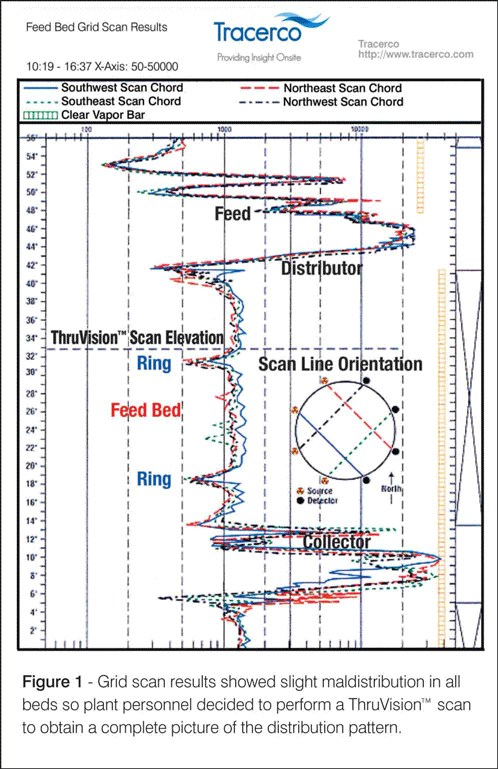

In the previous blog, we explained how Tracerco’s Tru-Grid™ Scan technologies can be used to diagnose suspected maldistribution in packed beds. In Part 2, we will discuss how we obtain more details on distribution within the packed bed.

A challenge to process engineers is diagnosing liquid maldistribution problems inside packed beds that can cause severe mass transfer efficiency loss. In industrial distillation columns, common examples of the cause of liquid maldistribution are design, manufacture or installation defects of distributors as well as damage, plugging and process disturbance of packed beds.

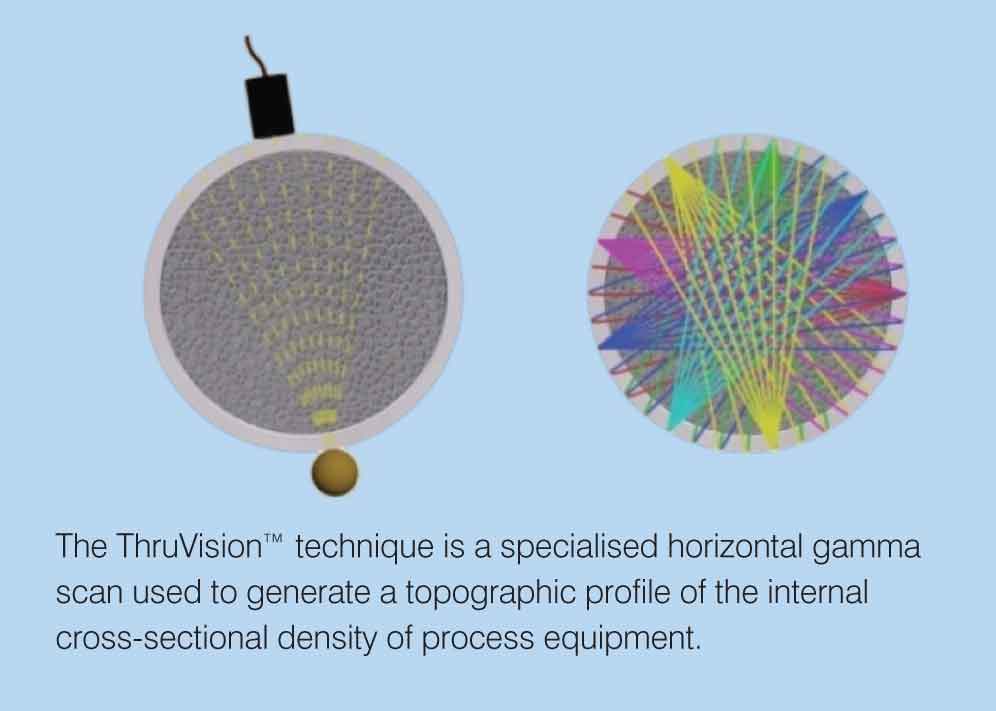

In this latest blog we will explain how following a Tru-Grid™ Scan, Tracerco’s ThruVision™ technology was able to obtain a more detailed liquid distribution profile of the packed bed.

Read More

Topics:

optimising plant processing,

plant processing,

scanning technology,

Process Diagnostics,

distillation column,

Distillation Column Performance,

packed column performance,

distillation tower scanning,

annular liquid distribution,

Liquid maldistribution,

packed column,

Suspected maldistribution,

distillation column maintenance,

ThruVision scan,

Tracerco technologies,

Suspected maldistribution in packed beds,

ThruVision

This post is the first of the "Diagnosing liquid maldistribution inside packed beds" series.

A challenge to process engineers is diagnosing liquid maldistribution problems inside packed beds that can cause severe mass transfer efficiency loss. In industrial distillation columns, common examples of the cause of liquid maldistribution are design, manufacture or installation defects of distributors as well as damage, plugging and process disturbance of packed beds.

In this latest blog, we will explain using a case study approach how Tracerco's scanning technologies can be used to diagnose suspected maldistribution in packed beds.

The first step to determine liquid maldistribution in a packed column is to perform a Tracerco Tru-Grid™ Scan to provide an initial look at the liquid distribution in the packing. A Tru-Grid™ scan consists of four equal-distant chords, one through each quadrant of the tower. Under ideal conditions and uniform liquid loadings, each scan plot will overlay closely with all others.

Read More

Topics:

optimising plant processing,

process systems,

plant processing,

scanning technology,

Process Diagnostics,

Gamma Scanning,

Distillation Column Performance,

packed column performance,

distillation tower scanning,

annular liquid distribution,

Liquid maldistribution,

packed column,

Tru-Grid Scan,

distillation column maintenance,

Tracerco technologies,

optimising plant production,

Suspected maldistribution in packed beds