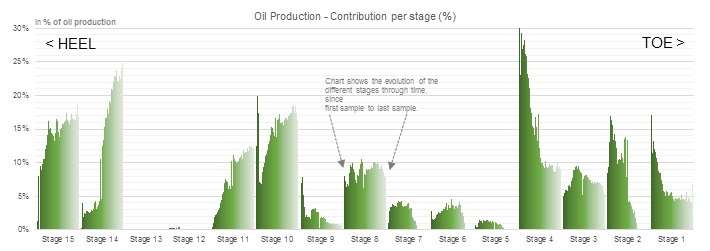

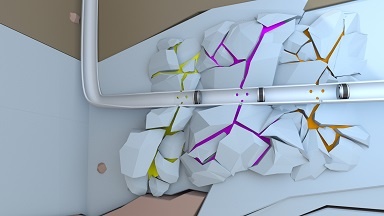

Selection of the stimulation target in unconventional shale formations is an important factor that impacts well productivity. In thick unconventional formations, it is essential that operators quantify the production of each stage of hydraulic fracturing executed in the well, in order to establish the most productive rock. It is also important for operators to be certain that every section of the stimulated well is effectively contributing to overall well production and clean-out of all stages has been achieved. In addition, other development challenges include optimal spacing between perforation clusters, stages and wells, allowing operators to optimize drilling and completion costs and maximize enhanced ultimate recovery (EUR).

This Blog describes the application of chemical tracers in a multi-stage horizontal well to gain insight on stage productivity in order to plan an optimal field development strategy.

Read More

Topics:

chemical tracers,

unconventional wells,

reservoir,

fracking,

reservoir characterisation,

tracers,

unconventional oil and gas,

smart tracers,

tracer technology,

frac wells,

shale,

shale production,

well development

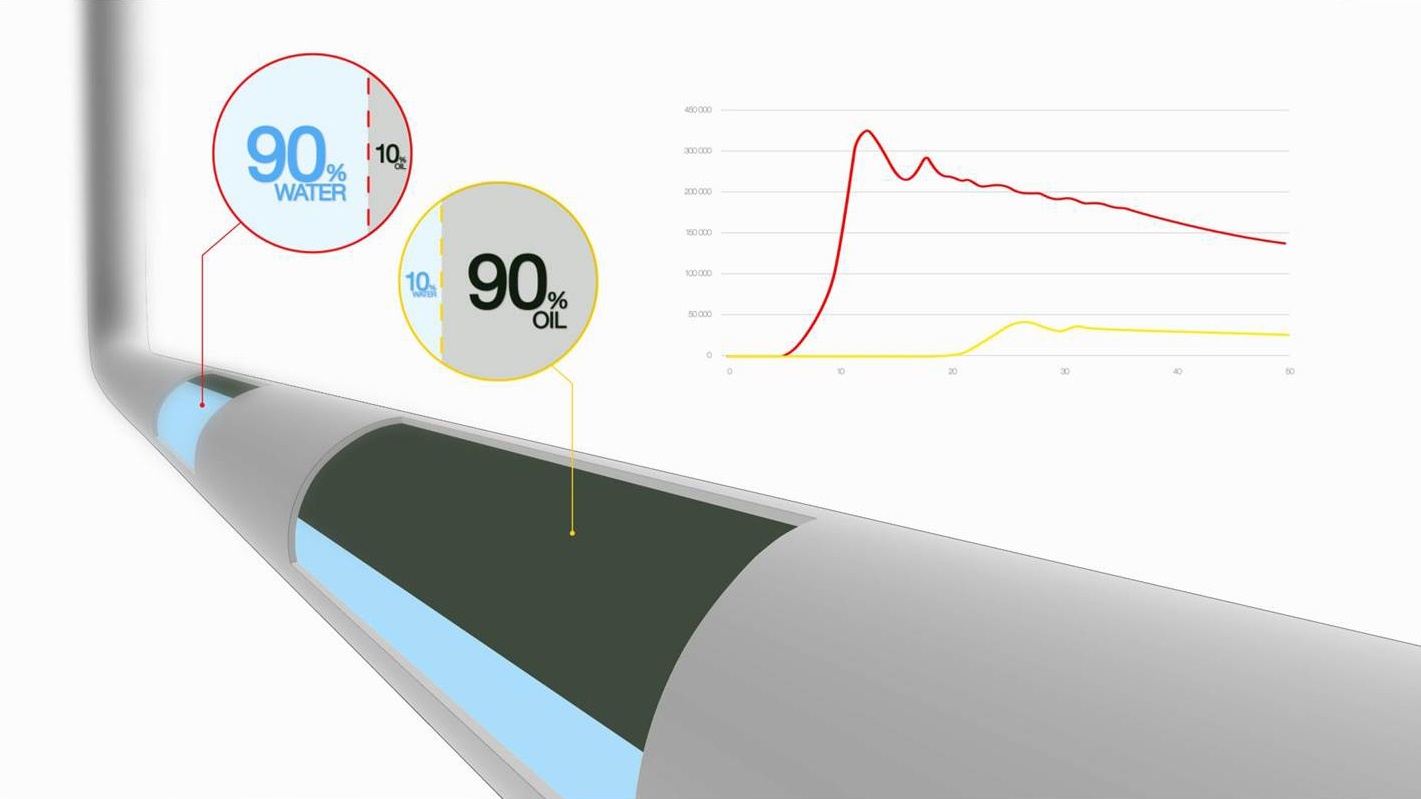

Tracerco, patented, pioneered and continues to enhance technology that enables the measurement of individual gas, oil, and water stage production along the length of a wellbore, without well intervention. This inexpensive technology provides confirmation that a wellbore is open to flow, identifies and quantifies stage flow contribution of each phase, and provides measurement of drainage area connectivity - simply by adding small amounts of unique chemical tracers to each stage’s stimulation fluid.

Read More

Topics:

chemical tracers,

unconventional wells,

reservoir,

fracking,

reservoir characterisation,

tracers,

unconventional oil and gas,

smart tracers,

tracer technology,

frac wells,

shale,

shale production,

well development

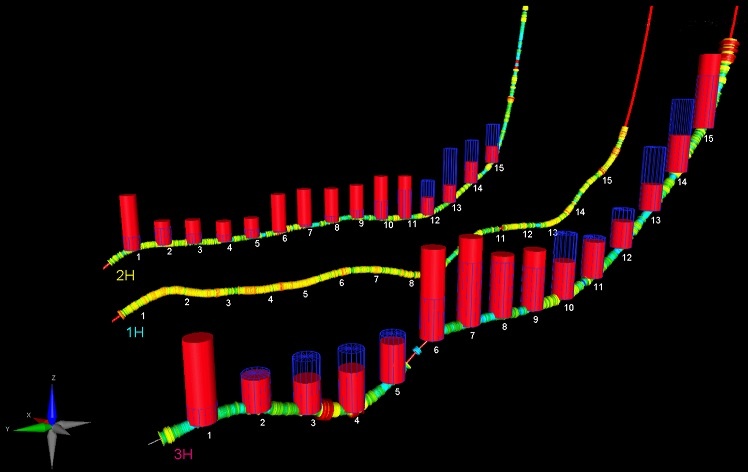

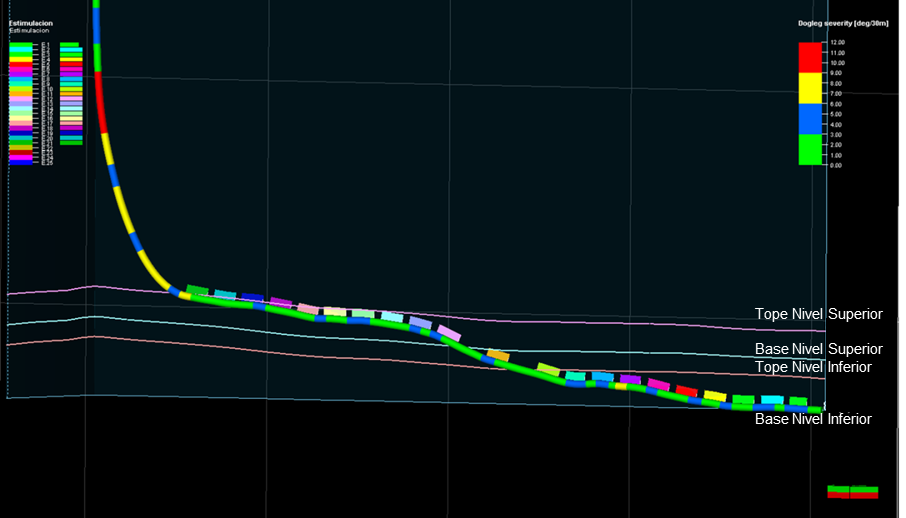

A customer wanted to test two different lithologies and compare the performance of both, in the gas window of the Neuquén Basin, in Argentina. For that reason, a slanted two-horizon target well was drilled, distributing 10 stages in the upper zone, and 10 stages in the lower zone. The intermediate zone, which was not considered a main target, received one stage.

21 unique organic gas and water tracers were added to each of the different stages of the well during stimulation. The injection was controlled and care was taken to tag all stages in the same way, ensuring that the tracers would penetrate deep into the fracture structure and make contact with formation hydrocarbons. Subsequent flowback and sample analysis for the presence of the injected tracers allowed relative gas and water flow from the different stages to be evaluated.

Read More

Topics:

chemical tracers,

unconventional wells,

reservoir,

fracking,

reservoir characterisation,

tracers,

unconventional oil and gas,

smart tracers,

tracer technology,

frac wells

In any deep water field development it is important to monitor oil and water production from all wells in order to manage fluid movement and maximize hydrocarbon output. The use of Smart Tracers integrated into a lower completion, alongside the use of waterflood tracers, provides a number of advantages over traditional oil and gas inflow measurement technologies, at a fraction of the cost.

Read More

Topics:

chemical tracers,

reservoir,

reservoir characterisation,

fluid inflow,

oil inflow,

water inflow,

oil production,

inflow measurement,

smart tracers

Understanding zonal contribution is imperative when developing stacked plays where a primary appraisal objective is to quantify zonal productivity to determine which layers of the formation to target. One proven evaluation method is the use of chemical-based tracer technology. In this blog post we will provide a real case example of where chemical tracer technology was used to determine zonal contribution and assist in the planning of future well and field development.

Read More

Topics:

chemical tracers,

unconventional wells,

reservoir,

fracking,

reservoir characterisation,

unconventional oil and gas

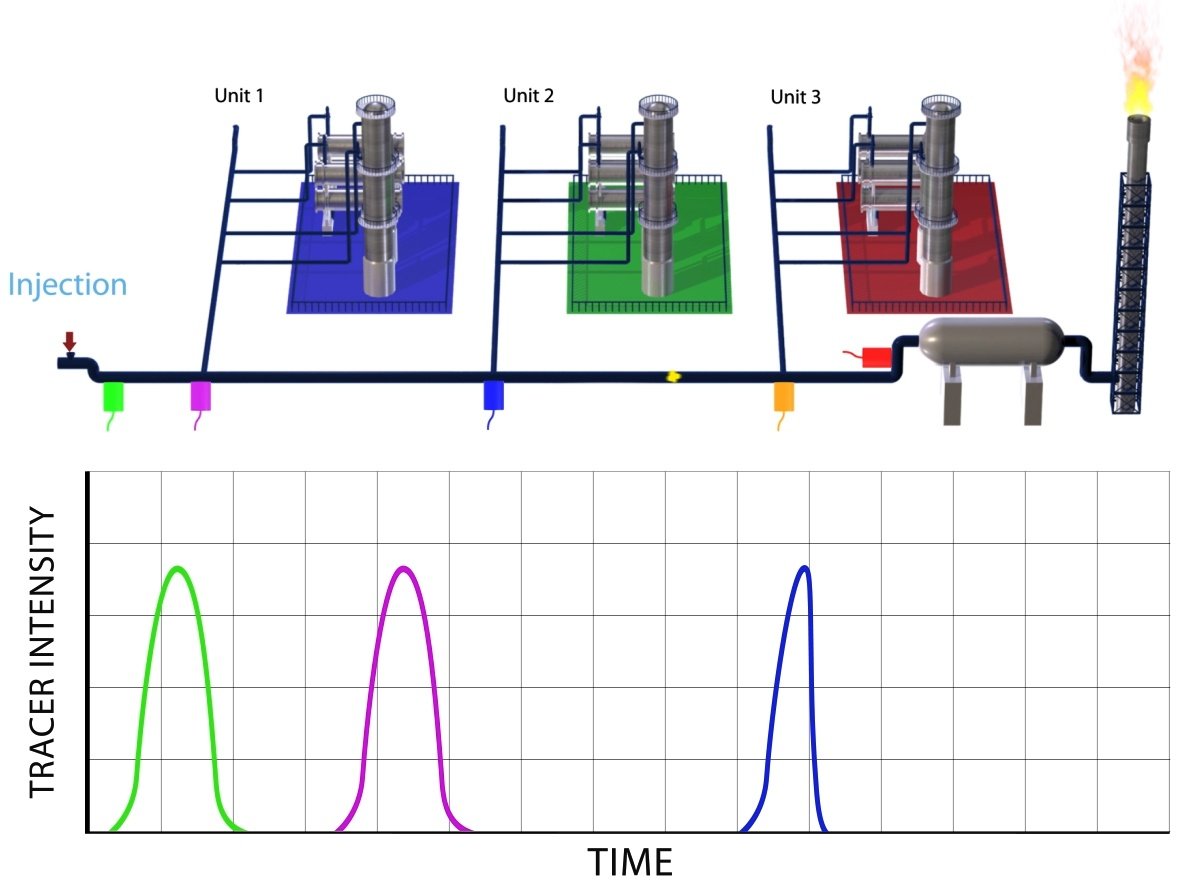

The verification of flare gas flow rates is an ongoing issue for many hydrocarbon producers globally, with strict environmental legislation continuing to impact oil or chemical processes. In this blog post we will review how the use of a Tracerco Diagnostics™ Flow Study can allow you to verify and calibrate flare flow meters, and locate the source of any fugitive flare flow, ensuring effective environmental reporting, as well as process optimisation and reduced downtime.

Read More

Topics:

Process Diagnostics,

flare gas flow meter,

gas flow meter proving,

flowrate,

flare study,

flare system tracers,

flare flow,

environmental reporting,

flare gas flow measurement,

excessive flare flow,

fugitive flare flow,

verify flow meters,

flare flow meter,

flow rate calculations,

calibrate flow meters,

Process Diagnostics Technology,

flare measurement,

flare gas meters

It is common in many oil refineries, chemical, ethanol and ammonia plants, for critical process equipment to experience problems. Issues in trayed towers such as internal tray damage, missing trays, plugged downcomers and tray foaming can all lead to off-spec production and in some cases, un-anticipated shutdowns. Scanning technology can help you avoid these scenarios by providing you with an assessment of your operating conditions, whilst your process equipment remains online. In this blog post we will feature the top three questions we are asked with regard to Trayed Towers and our Tru-Scan™ technology.

Read More

Topics:

Process Diagnostics,

Gamma Scanning,

Tru-Scan,

Tray Damage,

FrothView,

tower scan,

tower scanning,

tower gamma scan,

flooded trays,

process equipment,

Tray weeping,

tray fouling,

mechanical integrity

Offshore Northern Seas or ONS as it's more commonly known in Stavanger is one of my personal favourite events in the calendar. Occurring every two years, ONS is a must attend for anyone working in the oil industry in Europe and beyond. The last time I visited I could not help but be impressed by the spirit of innovation and the positive buzz around Stavanger for the duration of the show. Indeed, it is so popular that many locals leave the city for vacations and rent out their houses to visiting oil professionals in order to accommodate all the exhibitors and delegates who travel to the city for the show.

This year's event does not show any signs of being hit by the depressed oil price with 1,392 exhibitors confirmed and an additional conference arena being added this year. So why is it that the world's oil and gas industry home in on this event as a must attend in the calendar? Here are four reasons it should be on your agenda.

Read More

Topics:

oil & gas,

Events,

Upstream

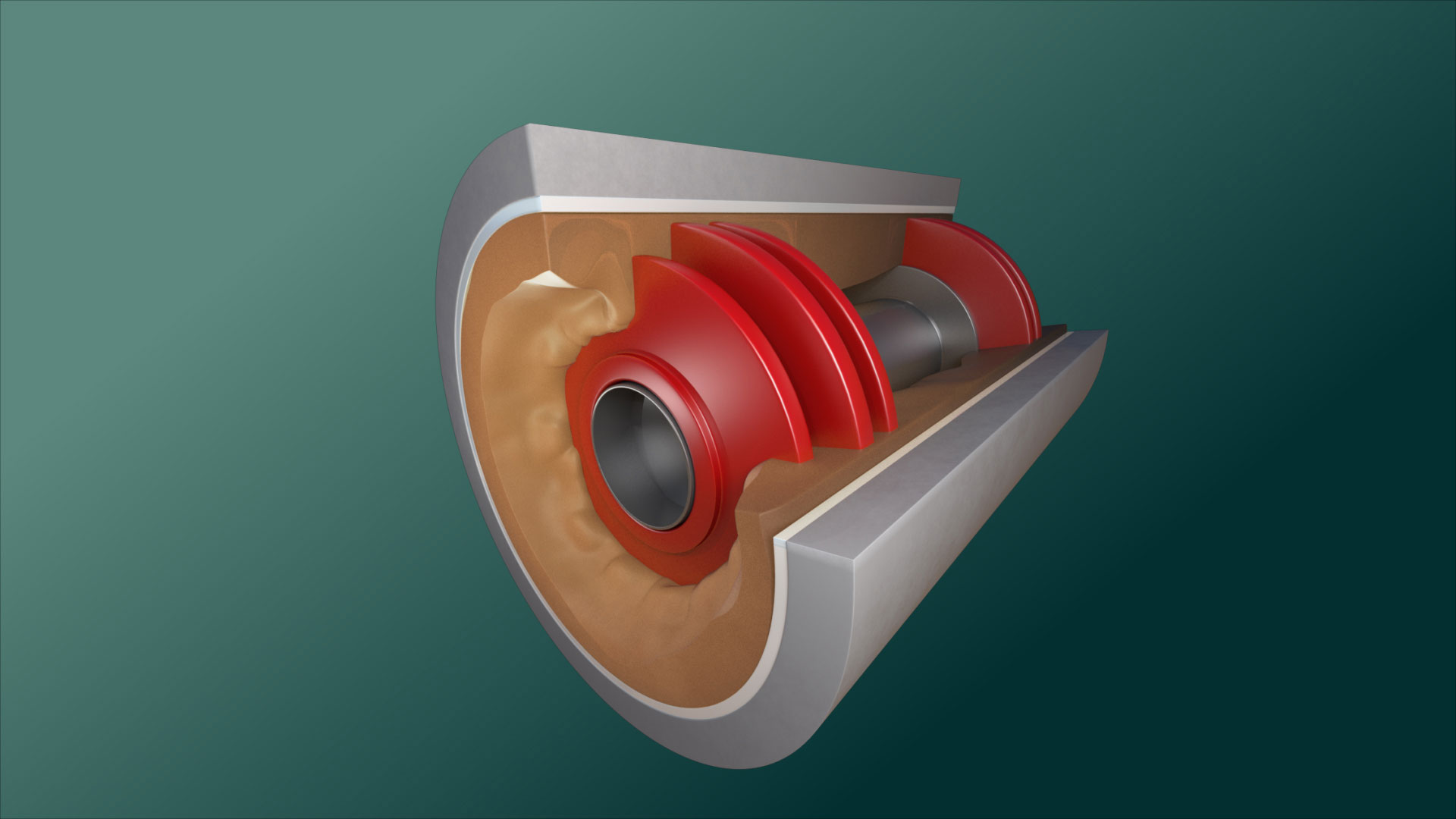

A Tracerco Diagnostics™ FCCU study allows refiners to identify operational and mechanical issues while the Fluid Catalytic Cracking Unit is still online. The use of Tracerco’s sophisticated scanning and tracer technologies allows refiners to improve productivity, maximise throughput, and plan any maintenance effectively. The insight provided from the study will lead to greater unit efficiency and higher profitability across the units run cycle. In this blog post we will discuss the top three questions we are asked with regard to a Tracerco Diagnostics™ FCCU study.

Read More

Topics:

plant processing,

Process Diagnostics,

tracerco diagnostics,

fcc unit,

fccu unit refinery,

FCCU,

fcc diagnostics,

fccu studies,

fcc riser,

fcc troubleshooting,

fcc unit process,

fluid catalytic cracking diagnostics,

fluid catalytic cracking services,

fluid catalytic cracking unit,

fcc cracking,

fcc process

It's a nightmare scenario no one wants... You run a PIG and it becomes stuck in the line. You now have an unsuccessful pigging campaign, a subsea pipeline blockage, and a missing PIG to deal with.

The cost of a shutdown due to a PIG stuck in a subsea pipeline can run into tens of millions in lost production, which is why it is absolutely critical to remedy the situation as quickly as possible. In this post we will examine the first step to remedying a blocked subsea pipeline due to a stuck PIG; that is locating the stuck PIG.

Read More

Topics:

pipeline inspection,

subsea flowlines,

Flow assurance,

Subsea Technology,

pipe bundles,

pipe in pipe,

Explorer,

scanning technology,

Flowlines,

subsea pipelines,

pipeline blockage,

pigging,

stuck pig