With fluctuations in the crude market from over-supply and negative prices to supply shortages and price wars, the diversity of crude is ever changing. And while it may be attractive to refinery purchasing, crude blending is often an overlooked after thought in relation to how certain process mixes can create unwanted operational challenges.

Nicola Porter

Recent Posts

How to gain control of your crude distillation unit (CDU)

Posted by Nicola Porter

Sep 30, 2021 11:07:12 AM

Topics: nucleonic instrumentation, desalter optimization, Tracerco Profiler, insights, nucleonic instrument, desalter performance, instrumentation, real-time measurement, real-time insights, multiphase separation, crude distillation unit, process control, process optimisation, instrumentation control, crude unit, CDU

How to use actionable insights to optimise trayed tower performance

Posted by Nicola Porter

Apr 29, 2021 10:35:15 AM

Gas plants play a critical role in cleaning raw natural gas after being extracted from subterranean deposits.

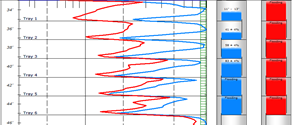

This process isolates hydrocarbons, non-methane fluids, hydrates and impurities to produce dry pipeline quality gas, which is then transported to the end user. These plants are generally low maintenance compared to oil refineries and most chemical processing complexes. However, they have limited options in the event of disruptions, degrading conditions or incoming raw gas flows. If these conditions do arise, scanning technology has proven to be an effective screening tool for providing detailed information about the hydraulic performance of trayed towers.

Topics: Tru-Scan, tower scanning, tower gamma scan, trayed columns, trayed tower, gas plant, insights, tower performance

How to ensure accurate and reliable pipeline pig tracking

Posted by Nicola Porter

Mar 24, 2021 7:38:56 AM

The ultimate objective of every pig run is to complete the required task, and return the pipeline to its original operating condition in the shortest time possible. A stuck pig causes delays, resulting in higher project costs, so it is important to have a contingency plan should the pig become stuck.

In this blog, we will discuss using a case study example how the implementation of our pig tracking technology allowed a customer to effectively and accurately track/time the pig trains progression down the length of the pipeline, thus resulting in huge savings on vessel and equipment costs.

Topics: pipeline inspection, pipeline integrity, pipe in pipe, subsea pipelines, pigging, stuck pig, pig tracking, gammatrac, pig run, pig tracking services

Using tracer technology to identify the source of fugitive emissions

Posted by Nicola Porter

Mar 23, 2021 10:54:54 AM

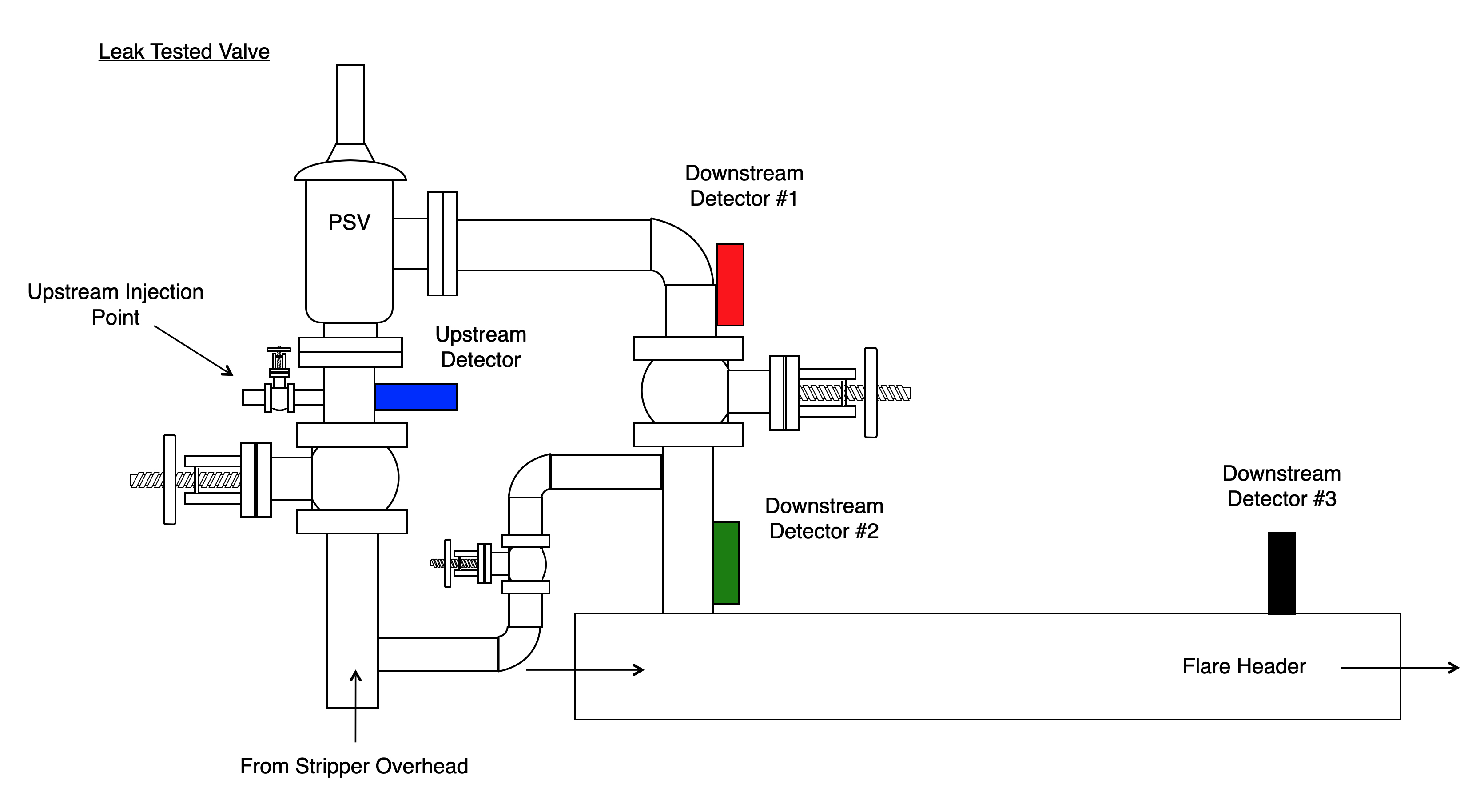

With government regulations constantly evolving and varying based on localities, being able to isolate sources of fugitive emissions and repair or replace faulty equipment allows customers to remain compliant and avoid costly fines. To aid in this endeavour, Tracerco injects a variety of liquid and gaseous tracers to detect the presence of leaks within equipment whilst remaining fully operational.

Topics: leak tests, small leaks, online leak detection, chemical leak test, pressure safety valve, leaking psv, leaking pressure safety valve, leak study, fugitive emissions, PSV, leak detection

Optimise oil production using inflow, interwell and completion integrity tracers

Posted by Nicola Porter

Mar 22, 2021 4:01:23 PM

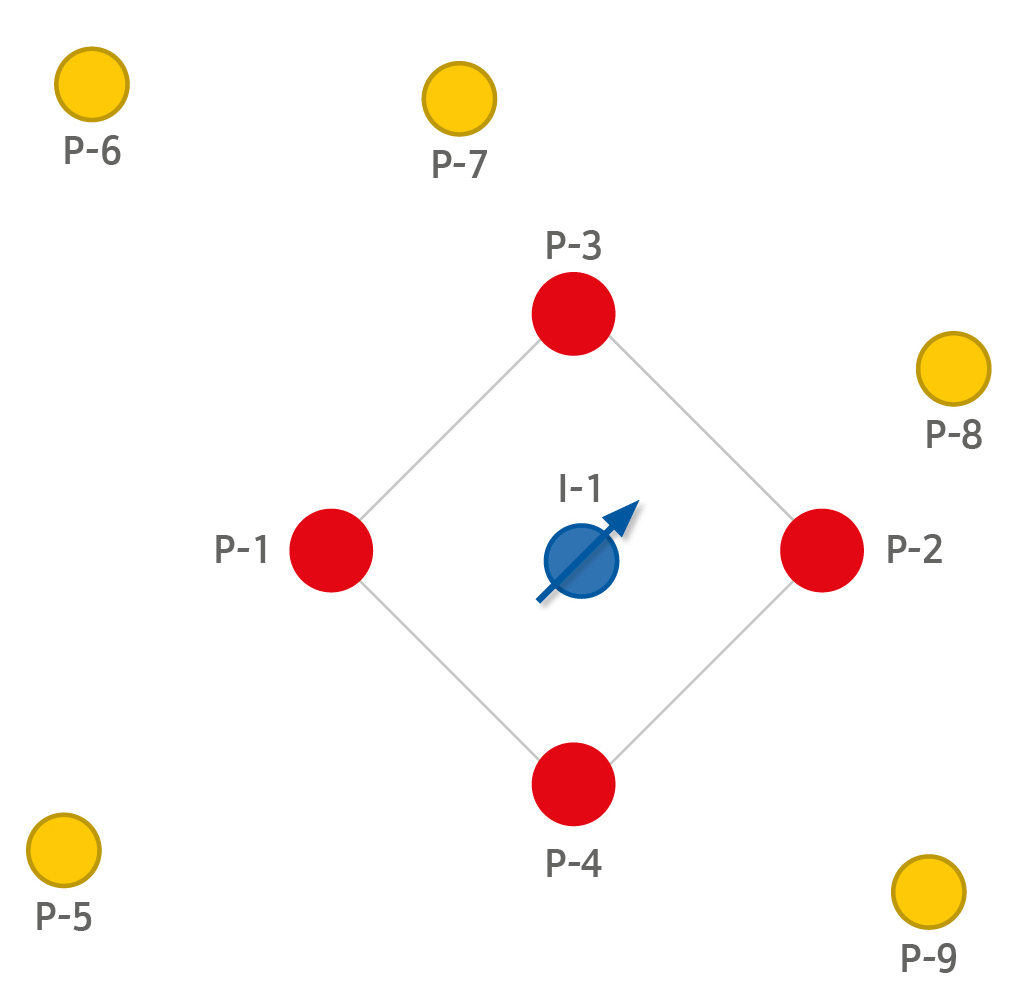

Mature oilfields are often characterised by increased water production. This results in costly water treatment and reduced oil processing capacity. Unwanted produced water may stem from well integrity failure, wellbore tortuosity, high waterflood injection rates, high permeability channelling, thief zones or injector / producer well spacing as well as water coning. Identifying the source of excessive water production and mitigating for its costly impact is critical during field development in reducing costs and maximising oil production.

Topics: chemical tracers, reservoir, interwell, reservoir characterisation, fluid inflow, tracers, oil inflow, water inflow, inflow measurement, inflow, waterflood, injected water, water breakthrough, water production, wellbore, mature offshore field, waterflood injection

Interwell partitioning tracers to measure the effectiveness of a chemical EOR flood

Posted by Nicola Porter

Mar 17, 2021 12:57:25 PM

Tracer technology is proven to be critical to assess remaining oil saturation measurement in a reservoir following secondary recovery. It allows the measurement of remaining oil saturation between wells, rather than just surrounding a wellbore. This technique is normally used before and after an Enhanced Oil Recovery (EOR) project to establish changes in crude oil saturation.

In this blog we will discuss using a case study example, how our range of specialist chemical tracers can allow operators to identify the amount of remaining oil saturation in a mature waterflood and determine the effectiveness of specific enhanced oil recovery techniques at reducing remaining oil to residual levels.

Topics: chemical tracers, reservoir, interwell, reservoir characterisation, fluid inflow, tracers, oil inflow, water inflow, inflow measurement, inflow, waterflood, injected water, water breakthrough, water production, water tracer, chemical tracer technology, wellbore, mature offshore field, waterflood injection, residual oil saturation, remaining oil saturation

Pre-turnaround scans enable better critical path planning

Posted by Nicola Porter

Mar 1, 2021 7:49:02 AM

Pre-turnaround scans are very useful tools for facilities to utilise for planning turnaround projects. They can indicate some damage within a vessel, allowing for parts to be ordered and onsite ahead of time. They can also indicate an operational issue, which can be corrected without an entry into the vessel. If required they can indicate that the vessel is healthy and no work is needed on it at this time.

Topics: distillation column, Distillation Column Performance, Column Performance, packed column performance, packed column, distillation column maintenance, gamma scanning distillation columns, trayed columns, turnaround schedules, turnarounds, distillation column scan, distillation column scanning, turnaround planning, packed bed towers, trayed tower, manage turnaround costs, turnaround critical path project, pre-turnaround scans, baseline scan, column troubleshooting, pre-turnaround planning, critical path planning

Baseline scanning is critical to diagnose future column problems

Posted by Nicola Porter

Jan 18, 2021 8:49:22 AM

Baseline scans of a vessel are undertaken when it is known to be clean, operating normally, and in good mechanical condition. They are often used for comparison purposes on future troubleshooting scans. Any anomaly, or abnormal absorption observed on a baseline scan, that cannot be explained by a visible external interference or by something indicated in the column drawings, may be able to be eliminated as a potential problem area in future troubleshooting scans.

Topics: distillation column, Distillation Column Performance, Column Performance, distillation column maintenance, gamma scanning distillation columns, distillation column scan, distillation column scanning, baseline scan, column troubleshooting

Counter fuel laundering and fuel adulteration using non launderable markers

Posted by Nicola Porter

Nov 20, 2019 1:02:48 PM

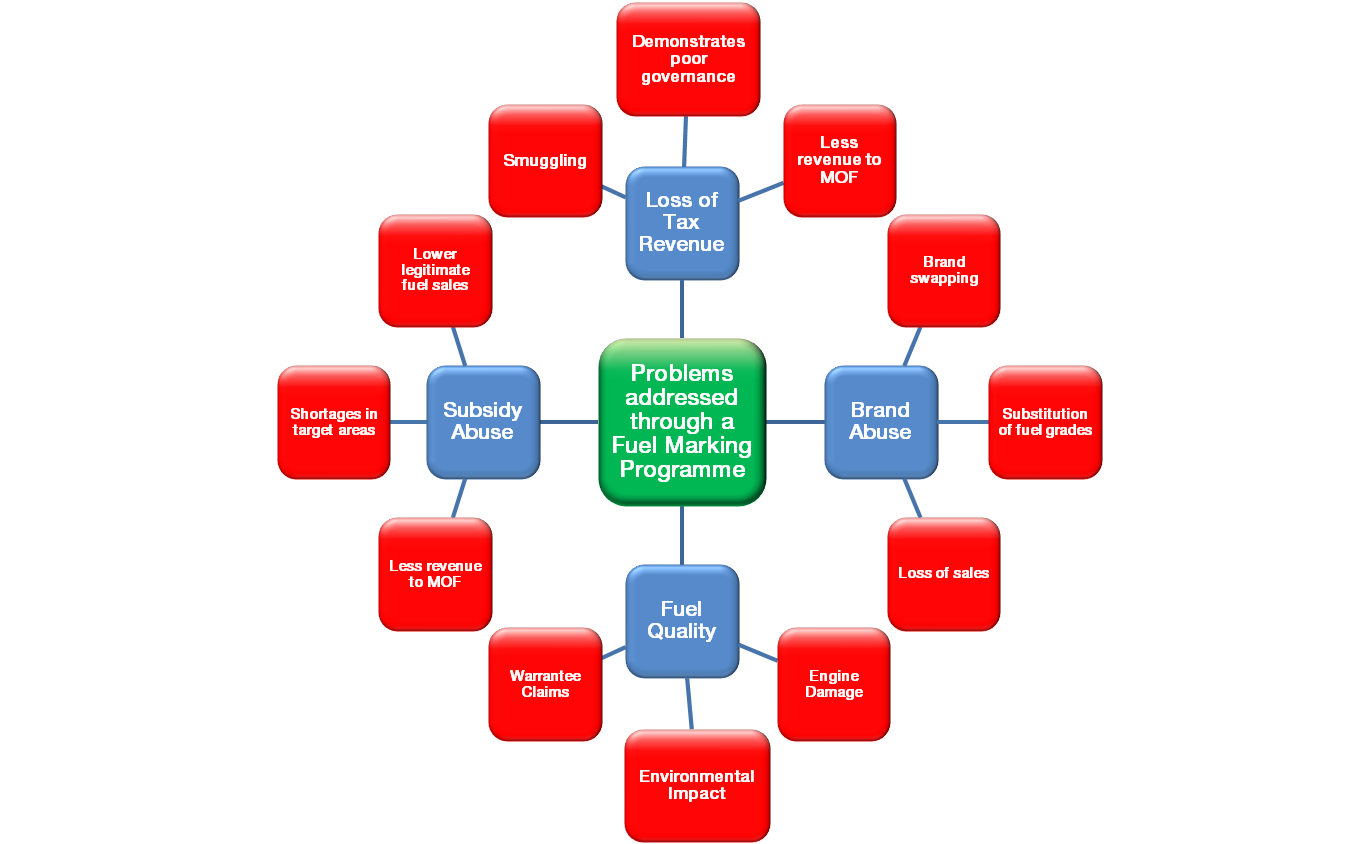

Fuel laundering, fuel adulteration and fuel smuggling combine to create a global problem for governments around the world. Not only does it deprive them of hundreds of millions of dollars of taxation revenues, it poses a burden to the environment and also to innocent motorists whose vehicles incur long-lasting damage. The cost in terms of policing, dismantling discovered plants, clean-up operations and the safe disposal of dumped toxic sludge — a by-product from such illegal operations — is also considerable.

Topics: authentication, consumer protection, product quality, revenue protection, fiscal tax recovery, adulterated fuel, brand security, counterfeit detection, product protection, product authentication, fuel fraud, brand protection technology, brand authentication, brand protection, safeguard brand quality

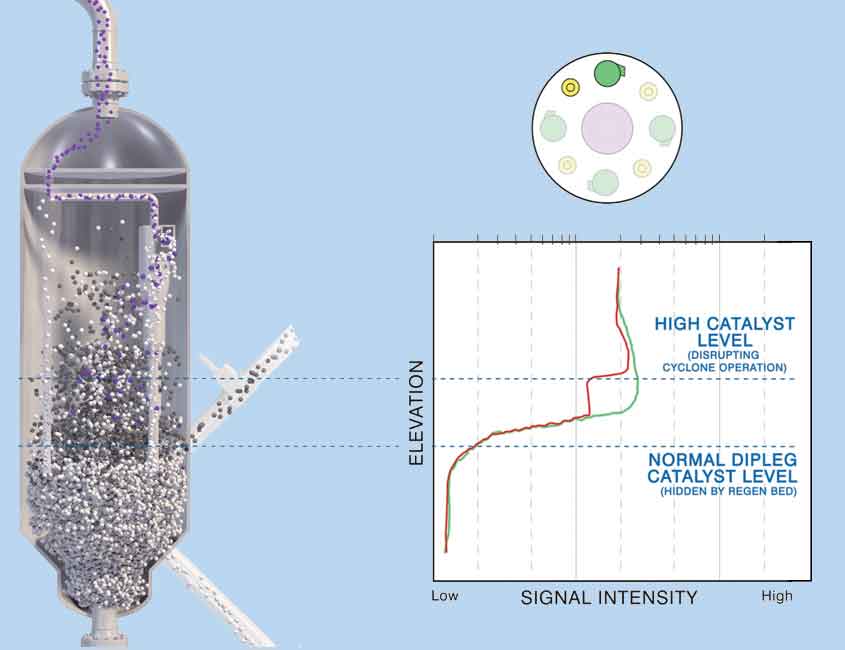

How to determine catalyst loss in FCC reactor or FCC regenerator cyclones: A case study

Posted by Nicola Porter

Jan 5, 2017 11:09:32 AM

The loss of catalyst through reactor or regenerator cyclones is a fairly common problem. Identifying the reason for the loss is often difficult.

In this latest blog, Tracerco, part of Johnson Matthey Plc, discusses how a Tru-Scan™ can be a powerful tool for gathering much needed information regarding the loss of catalyst.

Topics: Gamma Scanning, Tru-Scan, fcc unit, fcc, fcc diagnostics, fccu process, fccu studies, cracking unit, fcc troubleshooting, fcc units, fcc unit process, fluid catalytic cracking diagnostics, fluid catalytic cracking services, fluid catalytic cracking unit, Catalytic cracking, fcc cracking, reactor cyclone, gamma scan, fcc additives, fcc services, reactor distributor, riser reactor, fcc reactor, reactor riser, reactor stripper, regenerator cyclone, catalyst loss, Intercat, fcc addition systems

Oil and Gas Comment and News

Tracerco's news and comment on measurement and diagnostics in Oil & Gas and processing industries

Tracerco brings comment, news, how tos and more on their blog. Sign up for regular notifications of new posts.

Subscribe to Email Updates

Recent Posts

Posts by Topic

- reservoir (18)

- people (17)

- reservoir characterisation (17)

- Gamma Scanning (16)

- chemical tracers (16)

- employee recognition (16)

- Flow assurance (15)

- Life at Tracerco (15)

- Tru-Scan (15)

- gamma scan (15)

- pipeline inspection (15)

- Discovery (14)

- Process Diagnostics (14)

- Working Lives (14)

- pipeline integrity (14)

- tracers (14)

- Colleague Forum (13)

- Subsea Technology (13)

- subsea flowlines (12)

- Asset Integrity (9)

- subsea pipelines (9)

- Explorer (8)

- Subsea Inspection (8)

- Subsea Integrity (8)

- Tru-Grid Scan (8)

- liquid distribution (8)

- nucleonic instrumentation (8)

- Awards (7)

- PackView Analysis (7)

- fluid inflow (7)

- optimising plant processing (7)

- packed bed towers (7)

- quantitative analysis pack beds (7)

- reservoir analysis (7)

- unconventional wells (7)

- Distillation Column Performance (6)

- Liquid maldistribution (6)

- Process Diagnostics Technology (6)

- Suspected maldistribution in packed beds (6)

- desalter optimization (6)

- excessive flare flow (6)

- flare system tracers (6)

- fracking (6)

- interwell (6)

- packed column (6)

- pipe in pipe (6)

- pipeline blockage (6)

- pipeline life extension (6)

- process diagnostics technologies (6)

- tracer technology (6)

- CT scanner (5)

- Separator (5)

- Subsea flexibles (5)

- Tracer Study (5)

- Tracerco Profiler (5)

- Tracerco innovations (5)

- distillation column maintenance (5)

- gamma scanning distillation columns (5)

- inflow measurement (5)

- packed bed performance analytics (5)

- packed bed scan (5)

- pipe bundles (5)

- pipeline extension (5)

- plant processing (5)

- radiation monitor (5)

- smart tracers (5)

- tracerco diagnostics (5)

- tray fouling (5)

- water inflow (5)

- CT scanning (4)

- NORM (4)

- NORM Management (4)

- Subsea Technologies (4)

- chemical leak test (4)

- chemical tracer technology (4)

- density of liquid (4)

- fcc diagnostics (4)

- fcc troubleshooting (4)

- fcc unit process (4)

- fccu studies (4)

- feed/effluent heat exchangers (4)

- fluid catalytic cracking unit (4)

- fugitive flare flow (4)

- gulf of mexico (4)

- hydrocarbon separation train (4)

- instrumentation (4)

- instrumentation control (4)

- multiphase separation (4)

- north sea (4)

- nucleonic instrument (4)

- oil inflow (4)

- online leak detection (4)

- process control (4)

- radiation (4)

- scanning technology (4)

- tower gamma scan (4)

- tower scanning (4)

- trayed tower (4)

- unconventional oil and gas (4)

- water production (4)

- Column Performance (3)

- Decommissioning (3)

- Downstream (3)

- Flow Study (3)

- Flowlines (3)

- FrothView (3)

- NORM Detection (3)

- Naturally Occurring Radioactive Material (3)

- Packed Beds (3)

- Radiation Protection (3)

- Radiation Protection Adviser (3)

- Tray Damage (3)

- adulterated fuel (3)

- brand authentication (3)

- brand protection (3)

- brand security (3)

- catalyst bed wash (3)

- consumer protection (3)

- controlled release (3)

- counterfeit detection (3)

- delayed coke drum (3)

- desalting (3)

- distillation column (3)

- distillation column scan (3)

- distillation column scanning (3)

- distillation tower scanning (3)

- enhanced interface control (3)

- exchanger bundle leak testing (3)

- fcc cracking (3)

- fcc services (3)

- fcc unit (3)

- fiscal tax recovery (3)

- flare flow (3)

- flare gas flow measurement (3)

- flare gas flow meter (3)

- flare study (3)

- fluid catalytic cracking diagnostics (3)

- fluid catalytic cracking services (3)

- frac wells (3)

- gamma ray inspection (3)

- gas processing (3)

- increase production rates (3)

- increased separator efficiencies (3)

- inflow (3)

- injected water (3)

- leak detection (3)

- leak tests (3)

- manage turnaround costs (3)

- mature offshore field (3)

- monitor wash bed coking (3)

- neutron backscatter (3)

- nucleonic technology (3)

- off spec product (3)

- oil & gas (3)

- oil processing (3)

- optimising oil and gas production (3)

- optimising plant production (3)

- packed column performance (3)

- packing mal-distribution (3)

- ped (3)

- personal electronic dosimeter (3)

- process condition monitoring (3)

- process systems (3)

- product quality (3)

- profiler (3)

- radiation detection (3)

- radiation safety (3)

- revenue protection (3)

- separator performance (3)

- technology enabling cost savings (3)

- tomography scan (3)

- tower scan (3)

- trayed columns (3)

- turnaround critical path project (3)

- turnaround planning (3)

- turnaround schedules (3)

- turnarounds (3)

- verify flow meters (3)

- water breakthrough (3)

- waterflood (3)

- waterflood injection (3)

- well development (3)

- wellbore (3)

- Catalytic cracking (2)

- Damage to vessel internals (2)

- Depropanizer scan tray damage (2)

- Engineering (2)

- Events (2)

- Flooded Memeber Inspection (2)

- Flow distribution (2)

- High temperature plant processing (2)

- Houston events (2)

- INWED22 (2)

- Imagine the Future (2)

- International Women in Engineering Day (2)

- Inventors and Innovators (2)

- Level+ (2)

- Maths (2)

- PhaseFinder (2)

- Radiation Waste Adviser (2)

- SAGD (2)

- SRU Unit (2)

- STEM (2)

- Science (2)

- Subsea (2)

- Sulphur Recovery Unit (2)

- TENORM (2)

- Technology (2)

- ThruVision scan (2)

- Tracerco technologies (2)

- Tray Capacity (2)

- Upstream (2)

- Women in STEM (2)

- Women in engineering (2)

- annular liquid distribution (2)

- area monitoring (2)

- authentication (2)

- baseline scan (2)

- brand protection technology (2)

- coke (2)

- coke buildup (2)

- coke deposits (2)

- coke drum (2)

- coke drum cycle (2)

- coke drum optimization (2)

- coker optimization (2)

- column troubleshooting (2)

- counterfeiting (2)

- cracking unit (2)

- desalter (2)

- dose rate (2)

- dosimeter (2)

- drilling (2)

- employees (2)

- exchanger (2)

- fcc (2)

- fcc process (2)

- fcc riser (2)

- fcc units (2)

- fccu process (2)

- fccu unit refinery (2)

- fixed monitoring (2)

- flare flow measurement (2)

- flare flow meter (2)

- flare flowrate data (2)

- flare gas meter (2)

- flare gas meters (2)

- flare lines (2)

- flare measurement (2)

- flooded trays (2)

- flow profiling (2)

- flow rate calculations (2)

- flowrate (2)

- fouling (2)

- fouling deposits (2)

- fuel fraud (2)

- gas flow meter proving (2)

- gas meter proving techniques (2)

- grout monitoring (2)

- inflow tracer (2)

- insights (2)

- leaking exchangers (2)

- level detection devices (2)

- liquid restriction (2)

- marketing (2)

- mechanical integrity (2)

- monitoring (2)

- monitors (2)

- observa (2)

- oil in water (2)

- oil production (2)

- pigging (2)

- pre-turnaround scans (2)

- process diagnostics systems (2)

- process equipment (2)

- process vessels (2)

- product authentication (2)

- product protection (2)

- reservoir production modeling (2)

- residual oil saturation (2)

- safeguard brand equity (2)

- safeguard brand quality (2)

- safety (2)

- safety awareness (2)

- safety stand-down (2)

- separator study (2)

- shale (2)

- shale production (2)

- small leaks (2)

- solids buildup (2)

- stuck pig (2)

- tracer analysis (2)

- water tracer (2)

- well communication (2)

- work safe home safe (2)

- workplace safety (2)

- Ammonia converter (1)

- Be Safe (1)

- Blockages in perforated plates (1)

- CCS (1)

- CCUS (1)

- CDU (1)

- Carbon capture and storage (1)

- Carryover (1)

- Column Flooding (1)

- Demulsifier Chemical (1)

- Digital Marketing (1)

- EHS (1)

- EHS behaviour (1)

- EHS culture (1)

- EPD (1)

- Entrainment (1)

- FCCU (1)

- FMD (1)

- FMI (1)

- Global exchange (1)

- H2S Absorber (1)

- Heavy oil (1)

- InDepth (1)

- Intercat (1)

- Life cycle management (1)

- NORM Monitor-IS (1)

- NORM Survey Meters (1)

- OTC (1)

- PSV (1)

- Physics (1)

- Platform Members (1)

- Platform Memeber Integrity (1)

- Platform Structural Members (1)

- ROV-deployed instrumentation (1)

- SEO (1)

- Suspected maldistribution (1)

- ThruVision (1)

- Tracerco Day (1)

- Tray weeping (1)

- Water Ingress (1)

- Weeping (1)

- activities (1)

- adulteration (1)

- authentication solutions (1)

- authentication, product authentication (1)

- beer column (1)

- brand (1)

- brand protection tehnology (1)

- butadiene condenser (1)

- butadiene purification unit (1)

- calibrate flow meters (1)

- catalyst loss (1)

- celebration (1)

- coker units (1)

- counterfeit fuel (1)

- critical path (1)

- critical path planning (1)

- crude distillation unit (1)

- crude unit (1)

- crude vacuum tower (1)

- debutanizer (1)

- desalter maldistribution (1)

- desalter performance (1)

- distillation column service (1)

- distillation tower scan (1)

- distribution study (1)

- education (1)

- electronic personal dosimeter (1)

- environmental reporting (1)

- exchangers (1)

- extraction tower (1)

- fcc addition systems (1)

- fcc additives (1)

- fcc reactor (1)

- flare gas measurement (1)

- foam profile (1)

- fouled trays (1)

- fouling accumulation (1)

- fracture diagnostics (1)

- fuel adulteration (1)

- fuel marker (1)

- fuel marker technology (1)

- fuel marking (1)

- fuel smuggling (1)

- fugitive emissions (1)

- gamma ray inspection distillation (1)

- gamma scan distillationcolumns (1)

- gammatrac (1)

- gas flow meter prover (1)

- gas plant (1)

- gas undercutting (1)

- grout compliance (1)

- grout density monitoring (1)

- grout quality (1)

- health and safety (1)

- heat exchanger (1)

- heat exchangers (1)

- interface levels (1)

- leak study (1)

- leak testing (1)

- leaking pressure safety valve (1)

- leaking psv (1)

- liquid carry-over (1)

- liquid liquid extractor (1)

- marker systems (1)

- mass transfer diagnostics (1)

- medical (1)

- mental wellbeing (1)

- mobile tracer labs (1)

- monopile and jacket foundations (1)

- new technology (1)

- oil residence time test (1)

- outdoor fun (1)

- personal dosimetry (1)

- pig run (1)

- pig tracking (1)

- pig tracking services (1)

- plant performance (1)

- polymer tracer technology (1)

- polymerisation (1)

- popcorn polymer (1)

- pre-turnaround planning (1)

- pressure safety valve (1)

- process optimisation (1)

- process pipes (1)

- product assurance (1)

- providing insight onsite (1)

- radioactive source security (1)

- radiography (1)

- reactor cyclone (1)

- reactor distributor (1)

- reactor riser (1)

- reactor stripper (1)

- real-time density profiling (1)

- real-time insights (1)

- real-time measurement (1)

- refining (1)

- refractory depth (1)

- refractory lined pipes (1)

- refractory lined vessels (1)

- refractory loss (1)

- refractory measurements (1)

- regenerator cyclone (1)

- remaining oil saturation (1)

- reservoir fluid inflow (1)

- reservoir stimulation (1)

- responsive design (1)

- riser reactor (1)

- risers (1)

- safety behaviour (1)

- safety culture (1)

- safety education (1)

- separation tower scanning (1)

- separator systems (1)

- shutdown planning (1)

- shutdowns (1)

- source security (1)

- source theft (1)

- tower performance (1)

- trayed extraction tower (1)

- wash bed optimization (1)