At Tracerco, our people are at the heart of everything we do. Every role, every shift, and every story plays a vital part in our success. Through our Working Lives campaign, we’re shining a light on the individuals whose dedication, innovation, and teamwork power our business around the world.

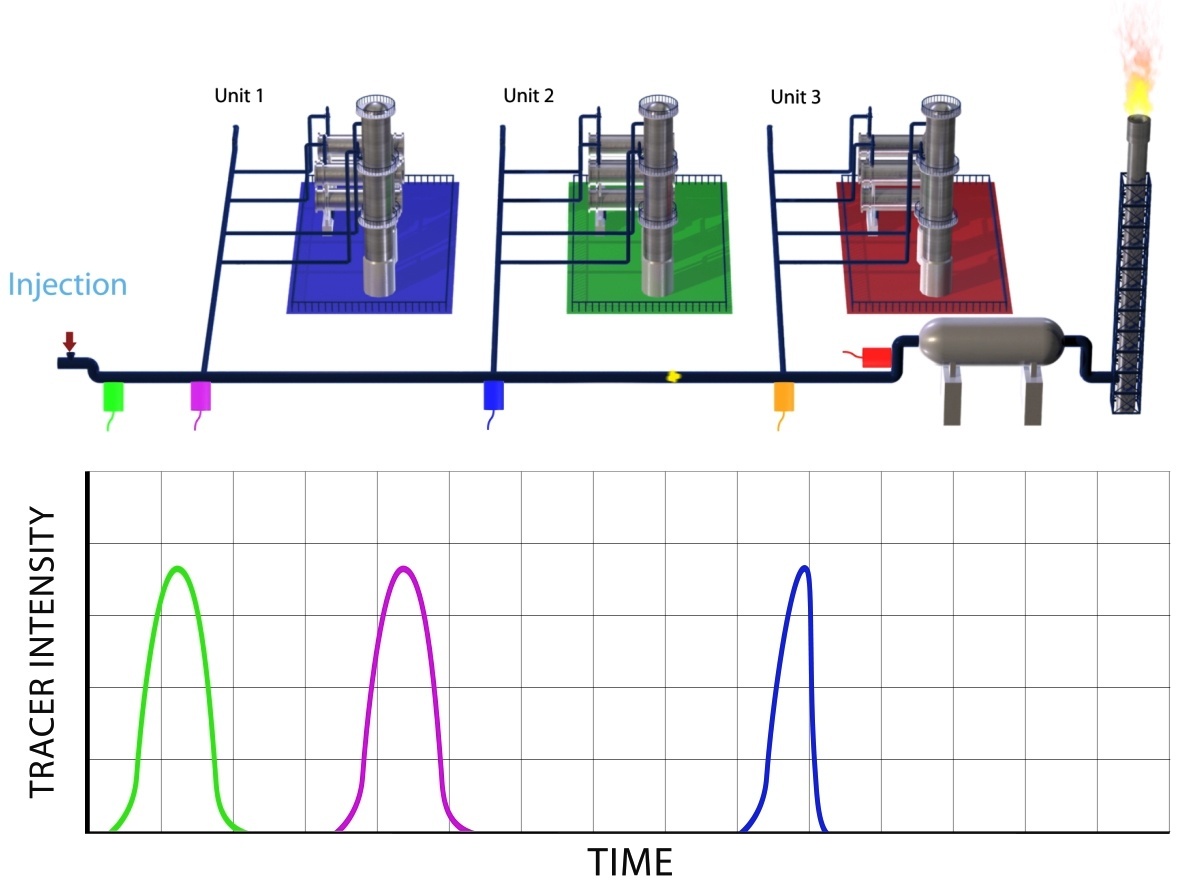

Today, we’re excited to introduce Vanessa, a Reservoir Technical Consultant based in Rio de Janeiro. With deep technical expertise and a passion for problem-solving, Vanessa plays a key role in helping our customers better understand their reservoirs using advanced tracer technologies to unlock critical insights.

Read More

Topics:

people,

employee recognition,

Life at Tracerco,

Working Lives

At Tracerco, our people are more than employees. They are at the heart of everything we do. That is why we are committed in providing opportunities that not only support our business growth but help our teams learn, grow, and thrive.

One of the ways we bring this to life is through our Global Exchange Programme. Merlin Cherian’s story is a powerful example of how international experience can ignite fresh thinking and deeper connection across our teams.

Read More

Topics:

people,

employee recognition,

Global exchange,

Life at Tracerco

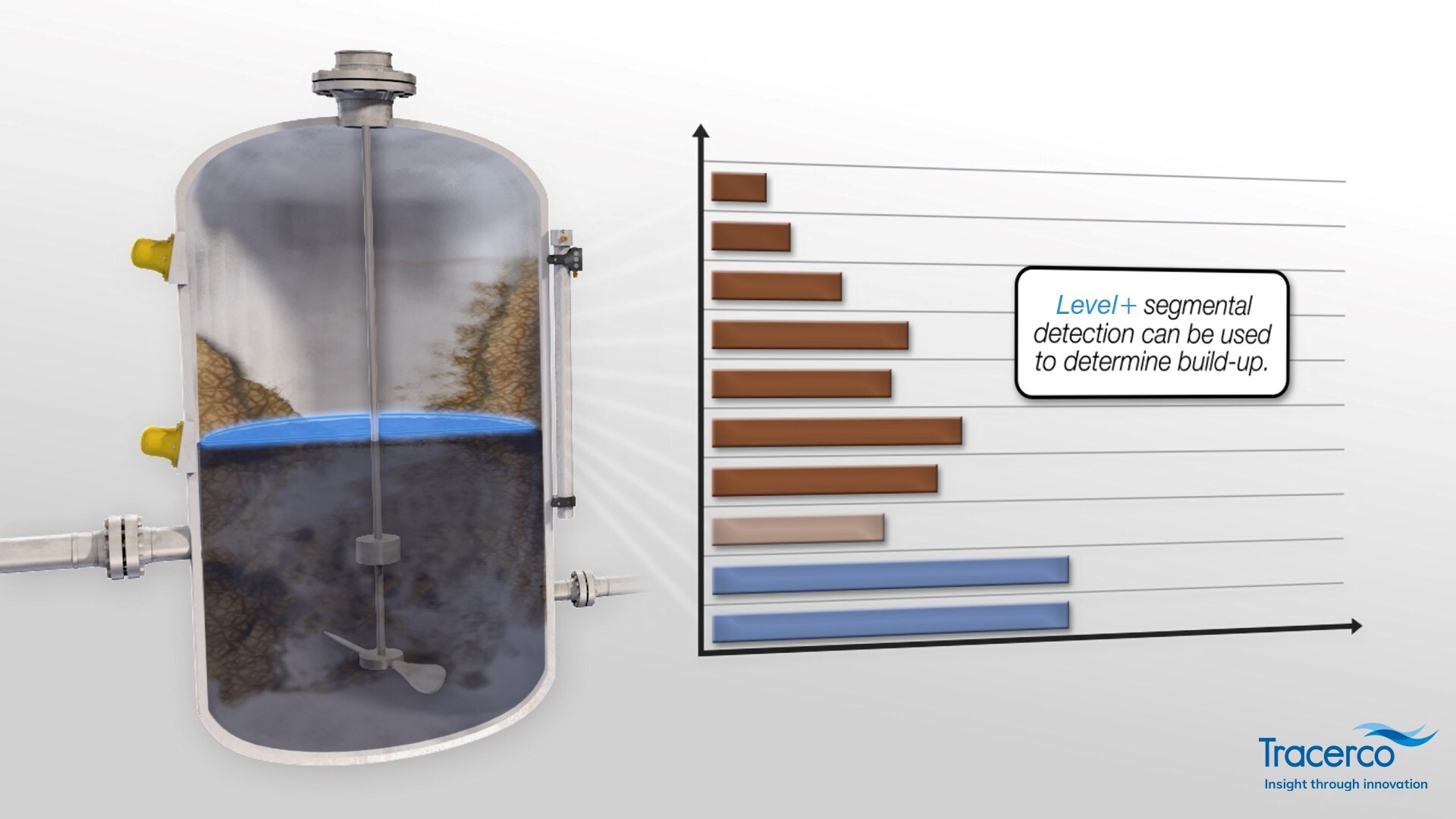

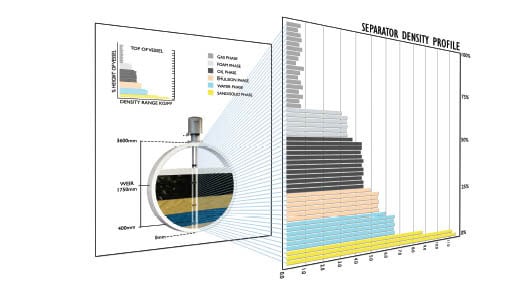

At Tracerco, we have always believed that the most effective tools are the ones that make their purpose clear. That is why we are excited to share some important updates to how we name our measurement instrumentation product portfolio. These changes are designed to help you quickly identify the right measurement solutions for your specific challenges, whether that is monitoring level, density, or internal process behaviour.

Read More

Topics:

nucleonic instrumentation,

Separator,

desalter optimization,

Tracerco Profiler,

nucleonic instrument,

separator performance,

instrumentation,

multiphase separation,

process control,

instrumentation control,

hydrocarbon separation train,

increased separator efficiencies,

nucleonic technology,

enhanced interface control,

process condition monitoring,

profiler,

Level+

The Asian petrochemical industry is experiencing rapid growth, driven by rising demand from sectors such as construction, automotive, packaging, and textiles. With massive investments in infrastructure and manufacturing across China, India, Malaysia, and Indonesia, the region is setting new benchmarks in petrochemical production. According to the International Energy Agency (IEA), China alone has added as much ethylene and propylene production capacity in five years as Europe, Japan, and Korea combined.

However, this growth presents challenges. Refinery owners must maximise throughput, improve efficiency, and reduce unplanned shutdowns, all while meeting increasingly strict environmental standards. In such a high-demand environment, precise process control is critical.

Read More

Topics:

nucleonic instrumentation,

Separator,

desalter optimization,

Tracerco Profiler,

nucleonic instrument,

separator performance,

instrumentation,

multiphase separation,

process control,

instrumentation control,

hydrocarbon separation train,

increased separator efficiencies,

nucleonic technology,

enhanced interface control,

process condition monitoring,

profiler,

Level+

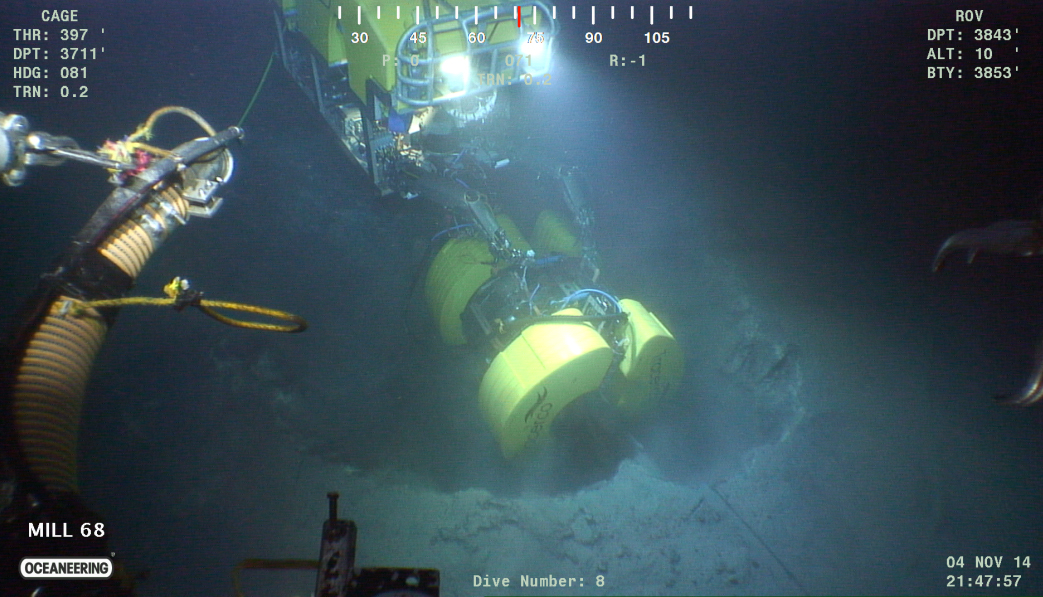

Keeping operations flowing smoothly

Flow assurance is at the core of offshore and subsea oil and gas operations. Ensuring uninterrupted transportation of hydrocarbons from reservoirs to processing facilities is a fundamental challenge, especially in deepwater environments where extreme pressures and temperatures can cause blockages. As the industry evolves, so too must our approach to diagnosing and preventing these issues.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Explorer,

Asset Integrity,

Subsea flexibles,

subsea pipelines,

pipeline blockage,

Subsea Inspection,

Subsea Integrity,

pipeline life extension,

pipeline extension,

CT scanner,

CT scanning,

gulf of mexico,

north sea

At Tracerco, safety is more than just a priority—it’s a core value that drives everything we do. As we mark World Day for Safety and Health at Work, we are especially proud to celebrate an incredible milestone: six years incident free.

Speaking about this achievement Rachel Burke, Director of Compliance and Risk said, “This achievement reflects the unwavering dedication and vigilance of every member of our team in upholding the highest standards of Environment, Health, and Safety (EHS).”

Read More

Topics:

safety,

safety stand-down,

safety awareness,

workplace safety,

work safe home safe,

Be Safe

High hydrogen sulphide (H2S) concentrations in flare systemspose significant operational and safety risks. To mitigate these risks, Tracerco conducted an advanced leak detection assessment on nine pressure safety valves (PSVs) within the Flare Header. The goal was to enhance safety, ensure regulatory compliance, and improve overall process efficiency using cutting-edge tracer technology and leak detection methodologies.

Read More

Topics:

Gamma Scanning,

tracers,

Tru-Scan,

leak tests,

gamma ray inspection,

flare system tracers,

excessive flare flow,

leak detection,

increase production rates,

optimising oil and gas production,

oil processing,

gas processing

In the demanding realm of subsea oil and gas operations, maintaining pipeline integrity and ensuring optimal performance of pipelines is paramount. At Tracerco our innovative technologies, notably Discovery™ and Explorer™, have set new benchmarks in non-intrusive subsea pipeline inspection. We offer operators unparalleled insights into asset integrity and flow assurance, helping them make informed decisions about their operations without compromising production.

In this blog we discuss how Tracerco can help you gain insight into how operators are leveraging these technologies to their advantage.

Read More

Topics:

Discovery,

pipeline inspection,

pipeline integrity,

subsea flowlines,

Flow assurance,

Subsea Technology,

Explorer,

Asset Integrity,

Subsea flexibles,

subsea pipelines,

pipeline blockage,

Subsea Inspection,

Subsea Integrity,

pipeline life extension,

pipeline extension,

CT scanner,

CT scanning,

gulf of mexico,

north sea

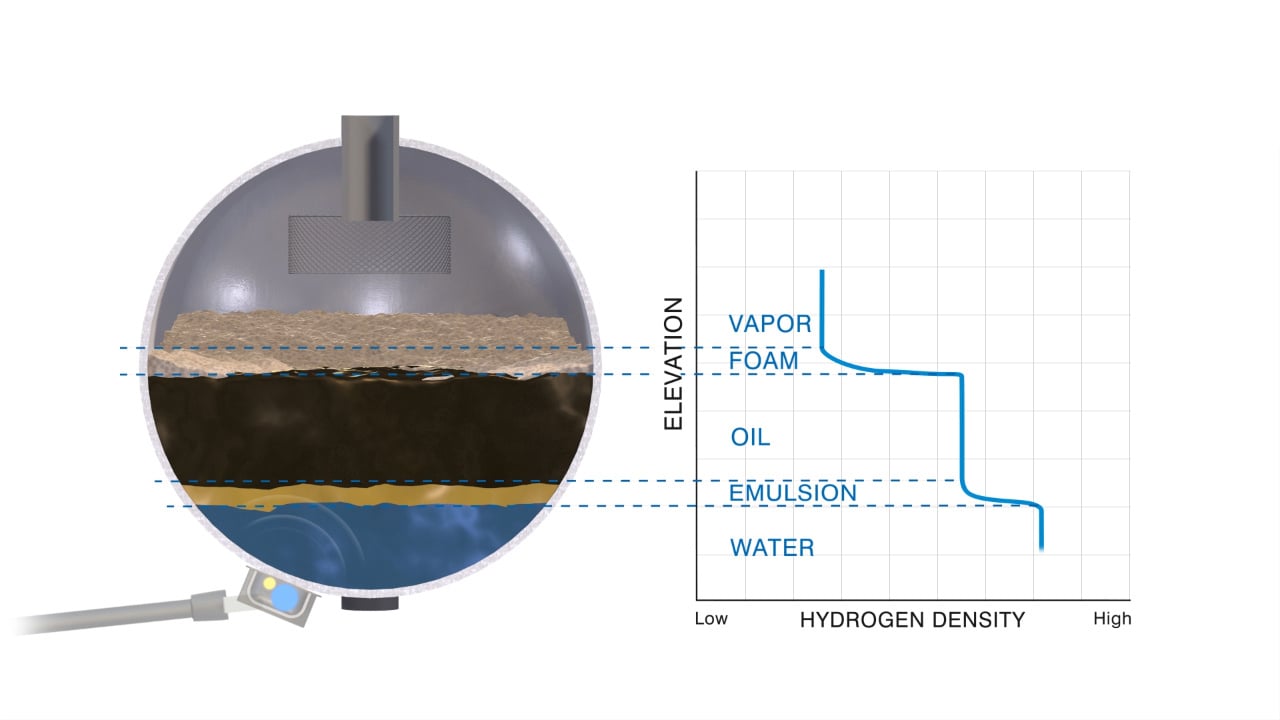

A nuclear level transmitter and multiphase measurement instrument, the Tracerco ProfilerTM has significantly improved operational efficiency and addressed various challenges in refining processes through its advanced process control equipment and nucleonic technology.

Read More

Topics:

nucleonic instrumentation,

Separator,

desalter optimization,

Tracerco Profiler,

nucleonic instrument,

separator performance,

instrumentation,

multiphase separation,

process control,

instrumentation control,

hydrocarbon separation train,

increased separator efficiencies,

nucleonic technology,

enhanced interface control,

process condition monitoring,

profiler

Understanding the significance of flaring in offshore, refinery, and petrochemical operations

Flaring has long been an integral part of offshore oil and gas, refinery, and petrochemical operations, serving as a critical safety mechanism to manage excess gas. However, with increasing environmental regulations and economic pressures, operators are scrutinising their flaring practices to minimise emissions and maximise efficiency..

Read More

Topics:

Gamma Scanning,

tracers,

Tru-Scan,

leak tests,

gamma ray inspection,

flare system tracers,

excessive flare flow,

leak detection,

increase production rates,

optimising oil and gas production,

oil processing,

gas processing

.png)

.jpg)